Leveraging Design for Sustainability Across Product Development

The term Design for Sustainability (DfS) is used to indicate considerations for sustainability are included in the design of a product. It is commonly related to environmental sustainability, but can include broader concepts of sustainability. The nature of DfS considerations and their effectiveness varies widely. Some products eliminate substances considered harmful to people or the environment. Others include technology to reduce a particular impact. Still others capture metrics to demonstrate reductions of impacts. The common theme is DfS considerations, relative to alternatives, aim to be less harmful, more sustainable or better for people and the environment.

The means of implementing DfS may vary, but they are most effective when metrics are included in the original intent of the product design. However, it is not enough to start out intending to design a more sustainable product, DfS metrics must be maintained throughout manufacturing, sourcing, production, delivery and beyond. Life cycle thinking should be incorporated into all aspects of product development. More sustainable products are the result of integrating a life cycle thinking approach throughout these processes and into extended manufacturer responsibilities. This article is an introduction to life cycle thinking methods for various product development phases.

Before product design begins, the challenge is identifying product performance goals. Since you cannot achieve unmeasureable goals, this step includes defining metrics for gauging these goals. Teams must first implement identifiable, quantifiable and measurable performance metrics. Successful product development companies revisit performance metrics often to verify their validity. They are frequently asking if the metrics continue to make sense given the current state of the product design and what metrics should be revisited for improvements.

Design teams verify that performance metrics are feasible. They predict and verify the expected performance based on prototypes, testing and analogous comparisons. Manufacturing and sourcing teams gauge the feasibility to continue meeting performance metrics for given supply chain options. Whether or not the metrics were achieved is captured and communicated for product production and delivery. Finally, performance metrics are continuously tested by consumers. It is a process of continuous verification, management and when necessary, adjustment. Many of us relate this process to things like functional performance, ease of use and manufacturability. However, like any of these other product performance metrics, this process extends to DfS performance.

Many of you are probably familiar with the above description through the foundations of Product Lifecycle Management (PLM). Companies implement PLM processes to manage projects as they transition between job functions and across departments. Among other things, they capture and track performance against specifications, project progress against goals, process identification and implementation and supply chain management.

Many companies currently use some type of PLM process for managing project progress. Rather than establishing a bolt-on parallel process for managing sustainability, it is preferable to integrate sustainability into one of these existing process. The following is not intended to applicable to exclusively to 'PLM processes,' but rather to any product development methodology. At the start of a product development process, product managers establish the original DfS performance intended for the product. However, they are not solely responsible for the ultimate DfS performance of the final product. Anyone that influences supply chain decisions for a product also influences the DfS performance. For this reason, DfS performance specifications should be included with other product performance specifications tracked in a PLM or product development process.

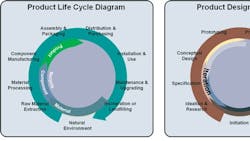

While they are complimentary, the lifecycle in PLM should not be confused with that in Life Cycle Thinking or Life Cycle Assessment (LCA). Lifecycle in PLM refers to the phases of product of product development -- ideation, concept development, prototyping, detail design and production. This is the product development phase of the product which establishes the life cycle of the product. The life cycle of the product refers literally the life of the product from cradle to grave. This includes the mine where the base materials originate, refining, manufacturing, assembly, transportation, usage and, finally, end-of-life of the product. Life Cycle Thinking and DfS aim to combine these two processes by expanding product performance considerations from being user-centric to being life cycle inclusive. Figure 1 contrasts these two terms.

Some examples DfS goals are reduce carbon footprint over last year's product, reduce ecotoxicity compared to similar products, minimize overall ecological impacts, reduce hazardous emissions throughout the product life or eliminate landfill waste. Notice all of these metrics are relative to a baseline or analogous product. This is is an important feature of DfS. All products use resources and result in emissions; thus a 100% sustainable product is not a feasible DfS goal. In addition to establishing DfS targets, it is important to identify the relative baseline for the targets. The specification phase offers the opportunity to establish or adhere to uniform and similar goals across all product lines.

Product development begins in earnest with several concepts. The process starts with several vaguely defined concepts. The concepts are refined through development and elimination. The feasibility of meeting performance targets also gets clarified. Many teams wait to evaluate DfS performance until later stages of the process due to the perception that it is difficult to evaluate DfS metrics on vaguely defined concepts. This perception arises because sustainability tools such as LCA require sophisticated and precision inputs. However, similar precision is necessary for evaluating the functional performance of a concept. For example, the actual performance of a drive train cannot be fully defined until every component is identified; yet, teams are able to select and define concepts early based on performance through the application of experience, best practices and guidelines. Like other performance metrics, best practices and guidelines for DfS targets need to be developed during this stage.

Since sustainability standards do not exist, best practices are refined over time. The importance of documenting progress against goals, results and lessons learned throughout the product development cannot be overemphasized. On one hand, teams learn what works and establish new baselines and guidelines for future product teams. On the other hand, teams also learn what doesn't work. They may even find DfS targets that do not accurately address the impacts they are attempting to reduce. One example is using a recycled materials to address the carbon emissions of a consumer electronic product. Depending on the power consumption scenarios, teams may find effort is better spent on efficient system architecture and task management rather than on identifying and designing with exotic 'green' materials.

Integrated design teams include manufacturing and production on the team, but even these best efforts leave many manufacturing and production questions unanswered until the design is complete. It is not uncommon for a design to undergo several changes during the transition into manufacturing and production. This is no different for DfS performance. Every design change results in a change in the DfS performance which may also result in the adjustment of targets. This requires evaluation to compare the performance of the new design with that of the original design. Good documentation eases the effort required to track and re-evaluate DfS metrics. Additionally, DfS metrics can be continually refined for pieces of the supply chain as they are identified. This eases the burden on final product evaluations that maybe used for marketing.

An important component to integrating DfS into the manufacturing and production of a product is the upstream supply chain.

The life cycle of the product does not begin with procurement of components, but with the source of the raw materials and all the processes necessary to make and deliver the component. This means the impacts on DfS metrics extends to suppliers and vendors outside of a company. This is competes with the notion that meeting DfS targets is the responsibility of the company providing the completed product. Extending this responsibility is similar to how product quality responsibility is extended. Communicating DfS metrics with suppliers should be managed the way quality metrics are managed. This requires providing DfS specifications and guidelines for reporting DfS metrics for all procurements. Since DfS metrics are not physically measured the way a tolerance is measured for quality metrics, uniformity of guidelines and understanding of results is necessary.

Integrating DfS into a product development process may seem like a daunting task. Integrating product quality programs were also once considered difficult. However, with the advent of product quality, many companies have implemented sophisticated processes for specifying, integrating, communicating and ensuring product quality. It is feasible to expand product quality systems to include, evaluate and track Design for Sustainability metrics. The management frameworks exist, it is just a matter of identifying goals and methods for integrating sustainability into these frameworks. In fact, integrating these metrics into an existing process is likely to result in broader acceptance of the metrics and faster integration.

Kimi Ceridon is a Sustainability Consultant, Kalepa Tech.

This article was made possible by the Society of Manufacturing Engineers Lean to Green Sustainability Tech Group.