So That Happened: Reshoring Boom Continues and Maybe Kids Do Like Manufacturing

Editor’s note: Welcome to So That Happened, our editors’ takes on things going on in the manufacturing world that deserve some extra attention. This will appear regularly in the Member’s Only section of the site.

High School Confidential

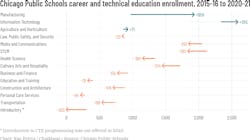

Are all those Manufacturing Day tours finally paying off? Enrollment in manufacturing education programs just about doubled between 2015 and 2021 in the Chicago Public Schools, according to data from Chalkbeat Chicago, an education-reporting website.

The chart comes from an article on the re-emergence of career and technical programs in Chicago and other urban school districts. With this growth, more Chicago students are enrolled in manufacturing training than any other vocational area besides information technology.

“‘This is where I see education going in the future,’” Martinez says. “‘I see a convergence of pre-K-12, higher education and industry all coming together.’”

New openness on the part of schools to partner with manufacturers looking to build tomorrow’s workforce? Needless to say, we’re all for it.

After reading several lifetimes’ worth of stories about undoing of manufacturing vocational training, we really can’t hear enough about new programs starting. So let’s close with another optimistic article around the subject, this one from Shaker Heights, Ohio: Manufacturing Their Own Success. And, dear readers, if you know of any other such initiatives, please email us with the details so we can shout it to the rafters.

Can you Create Inventors?

Well, Qualcomm thinks it can and has the numbers to show it’s doing a pretty good job.

It’s Thinkabit Lab program, which began in 2014, has inspired 85,000 students to look at inventions. And the company was involved in helping FIRST, the robotics competition, provide 23,580 students in 30 countries with opportunities to solve real-world problems.

Looking at 2021 over, the company said in its 2021 Corporate Responsibility Report, that they reached 561,063 students and 12,817 teachers.

This was done through the company’s social investments in the future workforce which include initiatives that:

- Bridge the STEM skills gap among students globally

- Build STEM capacity among teachers and educators

- Engage women and underrepresented minorities in STEM fields

- Leverage our employees as STEM ambassadors in our communities

And the company isn’t done. Its goal for 2025 is to “foster the next generation of innovators by inspiring 1.5 million students and teachers across the globe.

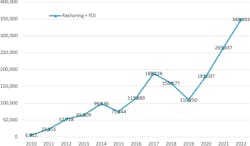

Reshoring Initiative: Supply Chain Risks Accelerate Reshoring

In 2021, reshoring and foreign direct investment (FDI) job announcements hit a record high, but industry was just getting started. Projections from Reshoring Initiative 1H 2022 data show reshoring and FDI continuing these gains. The current 2022 projection of jobs announced is around 350,000—another record and up from 260,000 in 2021. If the projection is achieved, 2022 will bring the total jobs announced since 2010 to over 1.6 million.

So far, the top three states by jobs announced are Kentucky, North Carolina and Georgia.

“With 5 million manufacturing jobs still offshore, as measured by our $1.1 trillion/year goods trade deficit, there is potential for much more growth. We also call on the administration and Congress to enact policy changes to make the United States competitive again,” Moser says.

Don’t sleep on the Midwest

More from the reshoring desk, courtesy of Encore Wire Corp. Chairman, President and CEO Daniel Jones: Speaking at a D.A. Davidson investor event this week, Jones said it’s clear the disruptions of recent years have given many more companies the impetus to shore up their supply chains and production networks. The Encore team, which markets electrical building wires and cables used in factories, data centers, apartments and more, is seeing onshoring demand rising in several corners of the country, Jones said.

In the Northeast, Jones laid out, the inventory of older facilities that can be upgraded is giving many companies a solid headstart. The usual growth-focused suspects Florida and Texas, meanwhile, are thriving thanks to population growth, “political reasons” and plentiful incentives. But, Jones added, “overlooked quite a bit” is the Midwest—represented on the Reshoring Initiative’s list of top 10 states by Ohio, Wisconsin and Michigan.

“It’s consistently pretty steady,” Jones said of the interest in investment. “The highs are not quite as high and the lows are not quite as low. With skilled labor and a real steady market, we’ve seen a lot of requests and a lot of activity.”

Being called consistent and steady without being given to extremes? We’re betting many a Midwestern manufacturing executive will nod and smile contentedly at that.

Stamping Giant Schuler Dives into Battery Cell Manufacturing

For many traditional automotive suppliers, the shift from internal combustion engines (ICE) to electric vehicles (EVs) is an existential crisis. If you’re making fuel injectors, now might be a time to explore new options because future generations of cars may not need them. However, future cars will continue to have doors, trunks, hoods and frames made out of metal.

Based in Villafranca di Verona, Italy, with sites in the St. Louis, Missouri, and China, Sovema supplies equipment for battery cell production from electrode shaping to the finished cell, with skills in process automation and power electronics.

About the Author

IW Staff

Find contact information for the IndustryWeek staff: Contact IndustryWeek