On the Journey to a Smart Manufacturing Revolution

In the 1970s and 80s, we witnessed a revolutionary wave of productivity improvements in manufacturing. New technologies, including personal computers (PCs), numerically controlled (NC) machines, programmable logic controllers (PLCs), and computer-aided manufacturing (CAM), combined with new process improvement ideas like Total Quality Management (TQM), Just-In-Time, and Six Sigma yielded great new levels of productivity and efficiency in many manufacturing industries.

Now, in this decade, we are seeing a similar convergence of technologies and process improvement initiatives with the potential to radically improve the way manufacturers thread processes and systems in the entire product value chain in order to deliver more options and new service models to customers.

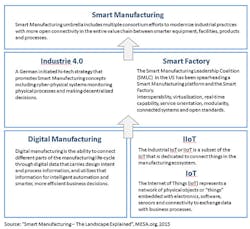

Several organizations that bring together manufacturers, technologies and information systems, organizations like MESA (Manufacturing Enterprise Systems Association), the Industrial Internet Consortium (IIC), and the Smart Manufacturing Leadership Coalition (SMLC), are working on initiatives including the Industrial Internet of Things (IIoT) and Smart Manufacturing to coordinate this convergence of technologies and realize the process improvement potential sooner rather than later.

Smart Manufacturing will enable proactive management of the manufacturing enterprise through informed, timely (as close to real-time as possible), in-depth decision execution. Smart Manufacturing initiatives share the following goals:

- Ability to receive published data from equipment using secure open standards, analyze and aggregate the data, and trigger process controls back to equipment, systems of record and process workflows across the enterprise and value chain connected via A2A and B2B open standards.

- Autonomous and distributed decision support at the device, machine and factory level.

- Ubiquitous use of mined information throughout the product value chain including end-to-end value chain visibility for each product line connecting manufacturer to customers and supplier network.

- Enhanced information- and analytics-based decision making on large amounts of raw data gathered from the smart manufacturing equipment and processes.

- New levels of efficiency to support new services and business models including mass customization (highly configured products) and product-as-a-service.

- Provide a broad portfolio of these advanced capabilities to manufacturers of all sizes and in all industry sectors, at acceptable levels of cost and implementation complexity.

Catalysts Driving Smart Manufacturing

Those are ambitious goals for Smart Manufacturing, but the following catalyst technologies and integration standards are coming together to provide the building blocks for this new revolution:

- Smart machines and advanced robotics – Smart machines communicate with manufacturing systems and display a high level of autonomy. These machines recognize product configurations and diagnostic information, and make decisions and solve problems without human intervention. Robots have enhanced sensors, dexterity and intelligence and perform tasks without being pre-programmed as they can learn from experience. Sensors make them aware of the environment and safer for the people around them.

- Industrial Internet of Things (IIoT) – Manufacturing devices with network and internet connectivity — from mobile tablets to smart shelves to sensors embedded in automation controls to smart machines — are active participants in event-driven, self-healing manufacturing processes integrated with open standards that support connectivity via the internet.

- Cloud services – Cloud software and platform services are delivered over the internet and enable ubiquitous, convenient, on-demand network access to a shared pool of configurable computing resources (e.g., networks, servers, storage, applications, and services) that can be rapidly provisioned and released with minimal management effort or service provider interaction.

- Enterprise integration platforms - Enterprise integration platforms, like Enterprise Service Buses (ESBs), Manufacturing Service Buses (MSBs), and API Managers, have the ability to receive data broadcast from equipment via secure open standards, analyze and aggregate the data, and trigger process controls, history recording, and work flows enabling business processes across the enterprise and value chain systems to be integrated via A2A and B2B open standards into a digital thread.

- Big data processing capabilities – Big data tools, like Hadoop, R, Storm and streaming analytics enable processing of large streams of data coming out of connected devices to support operational visibility, analysis and diagnostics over physical assets, processes and supply chains. Harnessing the power of big data analytics will allow manufacturers to not only analyze trends but also to predict events such as equipment lifespan, capacity fluctuation, and demand patterns.

Next Steps to Ubiquitous Smart Manufacturing

However, even with these great technical advances, organizations are working on Smart Manufacturing related initiatives because we are still falling short in some key areas to achieve the desired levels of connectivity in manufacturing processes. If we want these solutions to be broadly available to small and medium size manufacturing companies, we will need to work on the following areas:

- Broad adoption of machine-to-machine (M2M), application-to-application (A2A), and business-to-business (B2B) integration standards that will enable multi-vendor hardware and software plug and play solutions with open integration platforms to the internet. Organizations like ISO, IEC, NIST, and OAGi play a key role in establishing and promoting standards for connectivity.

- Data messaging standards that create a digital thread of communications from product definition in engineering systems to manufacturing in a multi-tier supply chain to product maintenance applications. Standards that not only distribute the product 3D definition but are also used to manage changes and record production history for traceability and archival purposes.

- New workforce skills will be required for the smart factory. Manufacturing IT personnel will need to learn about manufacturing systems, protocols for equipment integration, and how manufacturing data flows into business intelligence and corporate metrics. Workers will need to learn how to configure and maintain smart machines and robots.

In future articles, we will continue to chronicle the challenges and progress on the journey to Smart Manufacturing. In the meantime, hop on the bandwagon and get involved with some of the initiatives and organizations listed in this article. It is one way for your organization to be on the forefront of adoption and a step ahead of the competition.

About the Author

Conrad Leiva; VP Product Strategy and Alliances, iBaset

VP Product Strategy and Alliances

Conrad Leiva is VP Product Strategy and Alliances at iBASEt. His career has included consulting with many Aerospace & Defense companies on how to streamline the paperwork and information flow among Engineering, Planning, Quality, Production and Supply Chain disciplines.

Recently, Conrad has focused his work on manufacturing intelligence and the integration between engineering, business, and manufacturing systems working with PLM and ERP partners.

Conrad holds a master of science in Industrial Engineering from Georgia Institute of Technology, certificate from MESA on MES/MOM manufacturing operations management methodologies and is an ASQ certified quality auditor.

Conrad is chair of the Smart Manufacturing Working Group of MESA, the Manufacturing Enterprise Systems Association, and has co-authored MESA guidebooks on using information systems for Lean Manufacturing, and Quality & Regulatory Compliance.

He is a frequent speaker on Smart Manufacturing related topics.