Five Ways AR Apps Will Enhance Industrial Work in Next Five Years

There is a rightful excitement to augmented reality (AR) apps as the new technology is picking up the pace and getting wider adoption in business solutions. The name "AR" for these applications is somewhat restricted, as most industrial solutions include a mix of AR and its counterpart VR, or virtual reality. In the final outcome for the correct terminology, industries benefit from the mixed reality – the sum of both VR and AR – as a synonym for a technology that helps us bridge the gap between the physical and the digital worlds, and vice versa.

How to Link the Theory and Practice of AR Apps

Undoubtedly, being able to pick up insights from both worlds and use them to improve manufacturing processes has turned a new page for companies. However, there is a bump in the road. As the Microsoft Azure team states, engineers who work in manufacturing are grounded people who look for practical, tangible benefits. The extra layer of digitalization produced by AR apps is not immediately visible when it comes to industrial machinery.

When viewing augmented reality in the sense of mixed reality (AR plus VR), it’s obvious that the advantages of AR include extracting fresh information from the field with digital overlays, which is impossible if we only stick to industrial equipment per se.

An excellent way to understand the theoretical concept of AR, VR, and mixed reality is to observe reality on a continuum, where augmented reality mirrors the real environment and virtual reality is closer to the virtual environment. Workers operating in a real environment factory would use machines in the conventional factory system. Workers operating in a virtual environment would, for instance, use virtual factory floor planning supported by tools like the Oculus Rift.

In the next 5 years, we will witness the transformation of manufacturing as companies adopt augmented reality apps as a day-to-day tool to gather real-time operational insights, improve maintenance and servicing, design in 3D, reduce staff onboarding costs, and develop powerful remote collaboration platforms without the need to have teams in close proximity.

Setting the Scene for Industrial AR Application

There is an important development the manufacturers should keep in mind - developing AR apps is getting simpler than it used to be and the trend is expected to continue. In turn, such a trend will further reduce implementation costs as app developers gain experience in 3D development, computer vision, as well as in dynamic, interactive, and immersive UX practices.

As a bonus, developers have access to a resourceful base of AR tools. Google has ARCore. Apple has ARKit. Microsoft has HoloLens. There are even more platforms and SDKs that are helping manufacturing companies pick up the best fit. So, the environment is all set up.

At the moment, the big names are leading the wider industrial application of augmented reality. Following the natural development curve for innovative technologies, AR apps will take an exponential turn toward broader use as more tools and functionalities are crammed into less space. In a way, this is parallel to the classic Moore’s law, albeit in a slightly different way that encompasses more of the 21st-century emerging technologies, such as computer vision, face recognition, and artificial intelligence. Let’s look at some common applications of augmented reality in the manufacturing industries.

1. Simplified Assembly Instructions

Technical products consist of thousands of components. To assemble a car or a home appliance, factory workers need to keep track of dozens of spreadsheets, moving back and forth between a series of documents and field operation. AR apps can help by setting up a unified field for visible input, in which assembly instructions are presented in the same space, using voice control without hands. Airbus has implemented the AR app called MiRA to facilitate aircraft production with 3D models that monitor the integrity of the hydraulic equipment.

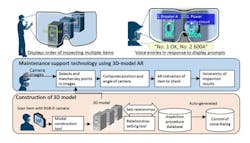

2. Efficient Equipment Maintenance

A similar and equally important segment of AR application is AR maintenance. Mitsubishi developed a 3D AR model that helps maintenance technicians follow the inspection order with AR smart glasses, using voice entry for the results. This augmented reality app significantly reduces the stress of a noisy work environment and improves productivity when building electrical systems or water-treatment plants.

3. Increasing Worker Productivity

Worker productivity has been a focus of General Electric, too. GE overlays graphics and video to the real world for almost a decade, but, since the technology is now cheaper, it has adopted it at scale. One example of a successful AR application is the elimination of critical mistakes in the process by collecting sensory input from the environment.

Combined with other advanced technologies, such as robotics and computer vision, it won’t be long before AR apps revolutionize the manufacturing context and make industrial processes more precise and less cumbersome for humans. Simply put, that’s what we expect from new technologies – to make our lives easier.

4. Lowering Operational Costs

AR apps can provide immersive, real-time, on-the-job training, which is irreplaceable for decreasing training costs in manufacturing industries, famous for the high technician turnover rates. All these tiny process improvements add up to reduced operational costs, especially when gauged against staff training costs, minimizing assembly errors and defects, and optimizing equipment repairs.

5. Quality Assurance

COQ (Cost of Quality) includes keeping an eye on hundreds of small details that accumulate over time and result in more expensive products. With AR apps, prevention costs, appraisal costs, as well as internal and external failure costs can be brought down to a minimum, simply because augmented reality adds another layer of checks of which the human eye is incapable. If we expand COQ in the organizational context, manufacturing industries could really communicate an important quality assurance message to customers by showing that they pay attention to detail in an unprecedented way. AR apps not only raise awareness about QA but also provide insight into a recently invisible field of improvements that can additionally profit in manufacturing.

At the moment, augmented reality may be the tool of the big names but as AR app development intensifies, so will the interest of smaller and medium-sized business keep rising. In the next five years, we will be looking at multiple micro improvements of the efficiency in the manufacturing process, which will be simple and cost-effective enough to be adopted without major research teams or long-term expert input innate for big organizations.

About the Author

Michael Kelley

Content Strategist

Michael is a professional tech writer and content strategist with an app development background. He specializes in Android & iOS app design, as well as blockchain & dapp technology.