Although 3D printing has reached the point where it’s no longer an emerging technology, intriguing new applications remain.

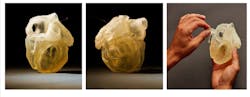

Consider, for instance, the potential benefits associated with printing digital anatomy.

Proving grounds

The Jacobs Institute, a Buffalo, N.Y.-based medical innovation center focused on accelerating device development in vascular medicine, has been testing the Digital Anatomy 3D Printer to re-create key vascular components for advanced testing and training.

“3D printing has been wonderful for recreating patient-specific anatomy compared to cadavers or animal models; however, the final frontier for organ model realism has been live-tissue feel and biomechanical realism,” said Jacobs Institute Chief Medical Officer Dr. Adnan Siddiqui. “That’s exactly what the Digital Anatomy 3D Printer gives us. We believe these models give us the best opportunity to recreate human physiological conditions to simulate actual clinical situations and to study new devices to establish their effectiveness before introducing them to patients.”

The new Stratasys J750 3D printer is expected to see adoption primarily by medical device companies, which require new ways to drive faster adoption of technologies and procedures - and academic medical centers, which are under increasing pressure to conduct training outside of the operating room to minimize risk to patients. The solution also supports efforts to move from time-based surgical training to proficiency-based evaluation.

Lifesaving potential for complex cases

While leveraging the 3D printed modeling process as a training tool has become a routine practice, the Jacobs Institute does not do it for every case. Doing so at this point would not be economical. However, the ability to print digital anatomy is an incredible resource when helping surgeons prepare for complex cases.

“It provides a streamlined process where we can take radiographic data to create anatomically true models,” says Siddiqui. “There is no question the process is getting faster and easier, but it is not straight forward for the novice."

And as printable materials continue to get better it allows for more advanced model differentiation. Siddiqui anticipates it will to come to a point where any major medical institution can use the technology to address complex case – whether it is going to be fee for service or onsite around the world is yet to be determined.

Expanded opportunities

Of course, the wider potential application for digital anatomy deals with being able to effectively advance the development of medical device technology. While medical professionals typically have a choice of cadavers, animal, traditional or virtual reality models, each route has significant limitations.

Unlike animal models that only approximate human anatomy and may raise ethical concerns, or cadaver models that cannot retain live-tissue feel and require a controlled environment, the Digital Anatomy 3D Printer recreates actual tissue response - and can be used anywhere without specialized facilities. It also lets users focus on specific pathologies. This ability to develop complex models ultimately enables medical professionals to conduct tests and gain a better understanding of device behavior whether it is intended for surgical treatment of strokes, aneurysms or heart disease.

“3D printing could really change this because as we develop more complex models, we can test effectiveness of strategies and devices compared to appropriate controls on standard of care,” he says. “We will always have to do human trials, but we can resolve effectiveness with the models.”

Road ahead

The biggest hurdle remains on the software side, and the next is in cleaning the model. “Current software does not do the complete conversion. It is doable, but the information you get will not be totally usable,” he says. “For effectiveness, we need to essentially duplicate the pulse and generate pressures just like the heart. You need to create the arteries and veins. That is impossible without labor intensive engineering – until we figure out a solution.”

About the Author

Peter Fretty

Technology Editor

As a highly experienced journalist, Peter Fretty regularly covers advances in manufacturing, information technology, and software. He has written thousands of feature articles, cover stories, and white papers for an assortment of trade journals, business publications, and consumer magazines.