Digital Molding Gives 3D Printing Six Sigma Repeatability

Over the years 3D printing solutions have replaced or augmented a variety of traditional processes. Creating jigs and fixtures, offering fast delivery of durable prototypes, custom-making prosthetics, and providing on-demand short-run parts are a few of the many ways 3D printing proves its worth daily. These reasons and more are why the 3D printing industry grew by 21% in 2017 according to The Wohler’s Report. 3D printing use grows because every day companies discover more ways additive manufacturing lowers operating costs, improves productivity, and offers equal or increased product durability.

Until recently, one important metric was not part of the 3D printing equation — production-run repeatability. 3D printing offered cost-saving speed, access to amazing materials, and a way to build complex and imaginative new parts. However, the ability to “dial in” print settings and have a full production run has been lacking. That ability is changing with the evolution of Digital Molding.

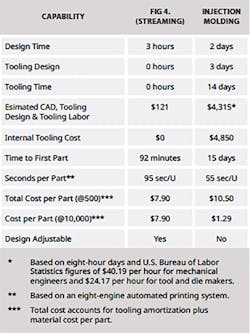

Digital Molding is the next advancement for 3D printing. It provides an immediate solution to tool-based thermoplastic molded production using lab-proven rigorous repeatability. New and advanced 3D printers will now behave like other manufacturing equipment, offering longer production runs and comparable repeatability. The tedious process of mold development and tooling is substituted by digital design that can be finished in a matter of hours instead of days or weeks. Although this methodology will not replace injection molding-based mass production, it offers an immediacy of production and a very rapid change of parts being produced. This occurs while tooling is still being designed and machined.

High-Volume Automated Production

Repeatability is non-negotiable for volume production. Existing thermoplastic manufacturing techniques offer standardized high-volume production with minimal run-time maintenance — the process is repeatable, for millions of parts. Digital Molding brings this level of repeatability to additive manufacturing. If eight 3D printers are set up to manufacture 10,000 parts, all eight must have identical settings that do not vary during the production run. Laboratory testing results confirm that Digital Molding processes based on the new 3D Systems Figure 4 system offers print speeds up to 100 mm per hour — at six sigma repeatability.

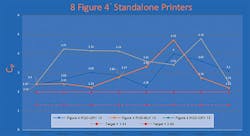

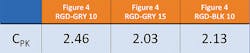

The statistical result is stated as Cpk > 2, where Cpk is the process capacity index. A result of 2 or higher is considered a “six sigma” quality process. To establish a Cpk value for the Figure 4 3D printing platform, tests were run on 8 machines individually. Cpk testing requires running 30 samples. The test parts were printed on each Figure 4 printer and measured using micrometers four times; the average was used for the statistical sample.

Next the physical model was adjusted, and new objects printed and measured again. The results for each printer from both runs were given their own results chart. The combined results scored 2 or higher, establishing six sigma quality in the repeatability of the process. Some individual results scored Cpk=1.94, not technically a six sigma result, but much higher than the nearest lower standard of 1.67 for "safety or critical parameter for new process."

Materials specialists, designers, and manufacturing engineers can now use Digital Molding to meet rigorous specifications for aesthetics, function, cost, and durability. Digital Molding can open the door to improved existing products, new designs, new business models, and new markets. The key is to know when to use additive manufacturing instead of conventional injection molding.

Materials scientists at 3D Systems have created a family of engineered thermoplastics specifically for Figure 4 — a broad and expanding range of materials to fulfill the role of Low Rate Initial Production (LRIP) of parts prior to mass production with injection molding.

Digital Molding Hardware

Digital Molding requires a production system, designed for fast scalability and customization to a manufacturer’s unique requirements. True industrial 3D printing, including Digital Molding, must account for the entire parts production process. Throughput is more than raw printing speed. It is the sum of printing, curing, and post-processing requirements across a period of time. Only when the part is ready for further manufacturing or shipping can throughput be considered complete.

The new 3D Systems Figure 4 Production platform is a set of individual modules that can be customized for specific needs. Each stage of the additive manufacturing process is automated, starting with an array of super-fast micro-DLP (Digital Light Printing) printers. These individual modules are combined with custom post-processing modules to enable automated part finishing at record speed, delivering to customers a Digital Molding engine.

System throughput is measured as vertical velocity. Depending on the geometry and material, a 3D object can be pulled from a 2D plane at speeds measured in millimeters per minute.

Smart manufacturing technology is central to Digital Molding. Robotic arms take the parts through every step of the primary and secondary processes. Digital inspection puts Industry 4.0 data capture and use into play. Industry standard protocols connect the Digital Molding system to other factory devices and to operations via Web and Cloud connectivity.

Scalability

Digital Molding is a toolless, volume production method for plastic parts. To work at volume, the technology must scale to meet a variety of factory situations. To be viable it must equal or exceed traditional injection molding in quality as well have acceptable speed. Benchmark testing found a Figure 4 Digital Molding system of eight modules can turn out 10,000 units of a textured automotive vent in 11 days; traditional injection molding tooling would be produced during those 11 days. Assuming injection molding starts after 11 days, Digital Molding could produce an additional 4,000 units of the vent in the same time that injection molding could produce 10,000.

Digital Molding does not need to replace traditional injection molding to be valuable. The CAD-to-production speed makes it ideal for Low Rate Initial Production (LRIP) or bridge manufacturing. Companies can go to market faster by starting with Digital Molding then switching or adding injection molding to ramp up volume as demand grows.

Complete Ecosystem

Digital Molding is an ecosystem. It requires hardware, materials, and software, all engineered to demanding expectations. To be the next innovation in additive manufacturing, a Digital Molding ecosystem must offer advanced printing, the latest in materials science, CAD software that understands the unique properties of Digital Molding, and robotics systems to automate the connections between modular operations.

When is the right time to invest in Digital Molding? When the four metrics of TCO, productivity, durability, and repeatability are in alignment. When business drivers such as time to market, production flexibility, and innovative design are required. When better/faster/cheaper and Industry 4.0 innovations arrive hand in hand. For the injection molding industry, the advent of Digital Molding means the time is here.

Philip Schultz is Senior Vice President, General Manager, On Demand Manufacturing & Plastics, 3D Systems Corporation, the company that created the 3D printing industry.

About the Author

Philip Schultz

Senior Vice President, General Manager, On Demand Manufacturing & Plastics

Philip Schultz is Senior Vice President, General Manager, On Demand Manufacturing & Plastics, 3D Systems Corporation, the company that created the 3D printing industry.