So That Happened: Gum in the News and More Grid Investments

Editor’s note: Welcome to So That Happened, our editors’ takes on things going on in the manufacturing world that deserve some extra attention. This will appear regularly in the Member’s Only section of the site.

And Then There Were Three

It's egg-laying time again at U.S. Steel Corp. That's right, even as the eventual fate of the venerable steel company remains far from certain, with Japan's Nippon Steel remaining adamant in its desire to acquire the Pittsburgh manufacturer, a bald eagle couple is moving forward with family plans at U.S. Steel’s Mon Valley Works Irvin Plant in West Mifflin, Pennsylvania.

The domestic situation has not been without drama, and it's not the bald eagle couple eager observers are used to seeing at Mon Valley Works.

Here's a little back story: Irvin and Claire had been nesting at the steel manufacturer's property since at least 2019 and hatched their first eaglet in 2020. As late as last spring, the couple were raising an eaglet in their woody nest.

Claire is now out of the picture. "Because there are so many bald eagles now in the area, we had a new female come in and took over the nest and challenged Claire," explained U.S. Steel Irvin Works plant manager Don German, according to CBS News.

This year Irvin has snuggled up with Stella, and the feathered couple have already laid three eggs. That's the first time there have been three eggs in the nest, according to the Pittsburgh Union Progress.

When will they hatch? You can watch for yourself, as Pixcams provides a 24-hour livestream video.

—Jill Jusko

China Bets Its Chips on Semiconductor Design

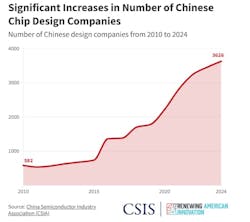

While the United States can’t compare with China and Taiwan in advanced semiconductor manufacturing, it is far and away the leader in advanced semiconductor design—locking in nearly half of all chip design sales globally and 72% of software and licensing sales for chip design.

In 2024, sales in China’s chip-design industry increased 11.9% from 2023, with the help of billions of dollars from the China Integrated Circuit Industry Investment Fund. The number of Chinese chip design companies grew by 175, to 3,626, in 2024.

“Many of these companies probably will go bankrupt,” the study concedes, “but the overall growth in the number of firms highlights China’s growing design industry.”

Having the advantage of a thriving manufacturing foundry network coupled with demands from its population of 1.4 million, China could develop into a leader rather than a follower, noted Wei Shaojun, vice president of the China Semiconductor Industry Association.

Some challenges for U.S. firms include rising development costs vs. the possibility of declining revenues from export restrictions and a shortage of highly skilled chip designers, a companion piece to the CSIS study observed. While U.S. universities lead in graduates with these skills, 65% are foreign nationals who may be up against labor restrictions in the U.S. Some will work overseas for the likes of Qualcomm and Apple, while others may start their own firms in their home countries, competing with U.S. firms.

—Laura Putre

Dallas to Meet Data Center Demands

Electronics manufacturing services company Flex announced Thursday a new 400,000 square-foot manufacturing facility for its data center power infrastructure solutions. The Dallas facility will expand production of power pods, power distribution units and switchgear.

“As AI adoption accelerates, the need for reliable, efficient and scalable power infrastructure grows,” said Chris Butler, president of Embedded and Critical Power at Flex. “Our new Dallas facility positions us to deliver next-generation power infrastructure solutions that help customers maximize computing performance while reducing deployment times.”

Flex joins Cummins and Eaton in supporting grid capacity growth, two companies mentioned in our last So That Happened column two weeks ago. Learn more about Flex’s investments to support the data center market in our latest episode of Production Pulse: America Needs More Electricity.

—Anna Smith

Mercedes-Benz Adding New Products to Alabama Plant?

It’s only one sentence in a much larger strategy plan released by the automaker, but Mercedes-Benz is suggesting that it could upgrade its Vance, Alabama, plant in the near future.

In announcing its 2024 financial results, the German automaker unveiled a raft of strategic plans that should run throughout the next several years, including plans to slash production outside if Europe by as many as 500,000 vehicles per year. But, don’t expect those cuts to come from U.S. operations.

By 2027, the company hopes to produce 70% of its vehicles in the countries where they’re sold, up from 60% today. As part of that strategy, “An additional Core segment model could be allocated to the United States.” Not exactly an iron-clad promise, but it’s something.

With the threat of tariffs on European auto imports constantly in the air, promising more U.S. production can also become a good political strategy.

Unrelated, but along those lines, Mercedes rival BMW announced Wednesday that it exported $10 billion worth of SUVs and cars from its South Carolina plant to Europe and the rest of the world last year. BMW has been a net vehicle exporter from the U.S. for nearly a decade as the SUVs made in Spartanburg aren’t made in the company’s European car plants.

BMW Manufacturing was the leading automotive exporter by value in the United States in 2024, according to data released this month by the U.S. Department of Commerce. Since 2014, the South Carolina plant has exported more than 2.7 million BMWs – about 63% of total production – with an export value of more than $104 billion.

—Robert Schoenberger

Elon Musk, The Distressed-Asset Investor?

Shareholders of Nissan Motor Co. enjoyed a few days of renewed hope after the Financial Times reported Friday that a former Tesla Inc. board member was leading an effort to have Elon Musk’s EV market leader lead an investment that would give Nissan a path out of its troubled state.

Merger talks between Nissan executives and their peers at Honda Motor Co. fell apart earlier this month after the latter reportedly insisted that Nissan become a Honda subsidiary rather than a full(ish) partner. So, Tesla to the rescue, in part because it could quickly scale via Nissan’s U.S. manufacturing plants?

Alas—despite some analysts and onlookers liking the sound of that tie-up. Both Musk and Hiro Mizuno, the former Tesla director, said early this week there was nothing to the report. Nissan shares promptly gave up all the gains they’d booked after the FT’s report—and then followed that up Feb. 25 by falling another 4%.

—Geert De Lombaerde

The Robots are Everywhere, Watching

Artificial intelligence “agents” are already all around you, observing and learning from your digital presence how to better serve you and replace human beings in our most basic interactions.

Deloitte consulting released last week a new quarterly report on the state of generative AI (GenAI) in the enterprise quarter. According to Deloitte’s data, drawn from over 2,700 interviews from directors and C-suite level respondents from six industries, between Q1 and Q4 last year, interest in GenAI from boards of directors and the C-suite fell markedly, while employees’ and technical leaders’ interest remained even, with 86% of tech leaders predictably showing the most interest.

Trust in GenAI remains moderate and senior decision-makers want to see the value from deploying the software, and soon. Only 21% of surveyed C-suite executives believe GenAi is already transforming their organization.

According to the data, worries about complying with regulations and risk management difficulties provide the greatest barriers to GenAI development and deployment, with each concern rising markedly throughout the course of 2024. Organizations are less concerned nowadays with a lack of technical talent and skills, however.

Tasks that rely heavily on logic, like code generation in IT, currently benefit the most from GenAI. While it would be an insult to say that writing code lacks artistry, generally speaking code uses repeated, proven language as a basis for software. AI is perfect for that sort of task.

The most interesting part of the report, I think, is the evidence that we’re entering the part of the hype cycle where the value of technology begins to prove out. 46% of respondents who said they were seeking the true benefits of GenAI reported uncovering new ideas and insights by using the technology.

The broad trend in GenAI is the development of “agents,” software given the agency to perform tasks with little if any human intervention. If you’ve interacted with a chatbot at your favorite online store to resolve a problem, you’re likely talking to an AI agent. Marketers use agents to shape campaigns based on survey data.

These are, finally, practical demonstrations that show what GenAI can actually do for us. Nothing to do with manufacturing, as I’ve been saying ever since the hype kicked off over a year ago, but good reasons to take the technology seriously if you haven’t before and start asking whether there’s something agentic AI might accomplish for your business.

Deloitte’s report also includes three brief GenAI case studies of banking, sales, and social media applications.

—Dennis Scimeca

Boosting the Building of Autonomous Ships

Coming soon: A shipyard that its backers say can be the hub of the U.S. Navy’s plans to rapidly grow its fleet of autonomous vessels.

Where that shipyard will rise has yet to be decided but Saronic Technologies CEO Dino Mavrookas recently told reporters that Texas and the Gulf Coast are being studied for the facility. Mavrookas and his team this month said they had raised $600 million from an investor group that are valuing the company at $4 billion.

Saronic has developed three vessels since its founding three years ago; the largest checks in at 24 feet, can hold 1,000 pounds and travel 1,000 nautical miles. To set the stage for the building of larger ships, the company’s leaders have hatched plans for the Port Alpha shipyard, which the newly raised dollars—and many more to follow—will help build.

“The velocity and economics of warfare have fundamentally evolved and several of our own team have witnessed firsthand how unmanned systems became true force multipliers in Afghanistan and in other theaters of conflict,” Paul Kwan of investment firm General Catalyst, which is a new investor, said in a statement. “Saronic represents a paradigm shift for our maritime resilience.”

—Geert De Lombaerde

Candy Industry Celebrates Decades of Bad Jokes

Bazooka!

Half of you just thought about a World War II era anti-tank gun, and the other half thought about aggressively pink gum with bad puns on its wrapper. Or to be fair, a lot of you thought about both simultaneously.

But you probably didn’t think about Ring Pops, Push Pops or Juicy Drop candies. Those all fall under the label of Bazooka Candy Brands, not just Bazooka Joe. Throughout the past 11 years, Bazooka Candy Brands CEO Tony Jacobs has tripled the company’s profits and more than doubling its size. He strengthened the company’s manufacturing and supply chain capabilities and developed marketing and product innovation, allowing Bazooka to break into new categories and channels.

In recognition of that, the National Confectionery Sales Association (the sweetest trade group in America) is awarding Jacobs with its 2025 Kettle Award, an annual recognition that the association says honors “dedication to confectionery manufacturing and operations, superior achievement in education and personnel training, energy and environmental contributions, quality advancement, production and plant improvement and research and product development.”

“The Kettle Award recognizes individuals who have made a lasting impact through leadership, innovation and dedication in the confectionery industry, and Tony Jacobs exemplifies these qualities,” said Audra Vogler, NCSA vice president and Kettle Committee liaison. “His contributions have strengthened not only his company but the confectionery industry as a whole, making him a truly deserving recipient of this year’s award.”

Bazooka gum got its start in 1947 and added the pun-filled wrappers in 1953. Watch this video for a 15-minute documentary from 2022 celebrating the company’s history.

—Robert Schoenberger

About the Author

Jill Jusko

Bio: Jill Jusko is executive editor for IndustryWeek. She has been writing about manufacturing operations leadership for more than 20 years. Her coverage spotlights companies that are in pursuit of world-class results in quality, productivity, cost and other benchmarks by implementing the latest continuous improvement and lean/Six-Sigma strategies. Jill also coordinates IndustryWeek’s Best Plants Awards Program, which annually salutes the leading manufacturing facilities in North America.

Have a story idea? Send it to [email protected].

Laura Putre

Senior Editor, IndustryWeek

As senior editor, Laura Putre works with IndustryWeek's editorial contributors and reports on leadership and the automotive industry as they relate to manufacturing. She joined IndustryWeek in 2015 as a staff writer covering workforce issues.

Prior to IndustryWeek, Laura reported on the healthcare industry and covered local news. She was the editor of the Chicago Journal and a staff writer for Cleveland Scene. Her national bylines include The Guardian, Slate, Pacific-Standard and The Root.

Laura was a National Press Foundation fellow in 2022.

Got a story idea? Reach out to Laura at [email protected]

Anna Smith

News Editor

News Editor

LinkedIn: https://www.linkedin.com/in/anna-m-smith/

Bio: Anna Smith joined IndustryWeek in 2021. She handles IW’s daily newsletters and breaking news of interest to the manufacturing industry. Anna was previously an editorial assistant at New Equipment Digest, Material Handling & Logistics and other publications.

Robert Schoenberger

Editor-in-Chief

LinkedIn: linkedin.com/in/robert-schoenberger-4326b810

Bio: Robert Schoenberger has been writing about manufacturing technology in one form or another since the late 1990s. He began his career in newspapers in South Texas and has worked for The Clarion-Ledger in Jackson, Mississippi; The Courier-Journal in Louisville, Kentucky; and The Plain Dealer in Cleveland where he spent more than six years as the automotive reporter. In 2014, he launched Today's Motor Vehicles (now EV Manufacturing & Design), a magazine focusing on design and manufacturing topics within the automotive and commercial truck worlds. He joined IndustryWeek in late 2021.

Geert De Lombaerde

Senior Editor

A native of Belgium, Geert De Lombaerde has been in business journalism since the mid-1990s and writes about public companies, markets and economic trends for Endeavor Business Media publications, focusing on IndustryWeek, FleetOwner, Oil & Gas Journal, T&D World and Healthcare Innovation. He also curates the twice-monthly Market Moves Strategy newsletter that showcases Endeavor stories on strategy, leadership and investment and contributes to other Market Moves newsletters.

With a degree in journalism from the University of Missouri, he began his reporting career at the Business Courier in Cincinnati in 1997, initially covering retail and the courts before shifting to banking, insurance and investing. He later was managing editor and editor of the Nashville Business Journal before being named editor of the Nashville Post in early 2008. He led a team that helped grow the Post's online traffic more than fivefold before joining Endeavor in September 2021.

Dennis Scimeca

Dennis Scimeca is a veteran technology journalist with particular experience in vision system technology, machine learning/artificial intelligence, and augmented/mixed/virtual reality (XR), with bylines in consumer, developer, and B2B outlets.

At IndustryWeek, he covers the competitive advantages gained by manufacturers that deploy proven technologies. If you would like to share your story with IndustryWeek, please contact Dennis at [email protected].