There is a reason why rail freight continues to move nearly 40% of North America’s freight per ton-mile – it is efficient with significantly lower emissions. How efficient? Specifically, rail can move one ton of freight 470 miles per gallon of fuel (approximately three to four times more fuel efficient than moving freight by truck), yet rail only accounts for 8 percent of the freight-related carbon emissions.

Of course, the opportunity exists to making rail freight even more efficient. As such, Pittsburgh-based Wabtec Corp. has made optimizing rail efficiency one of its key goals with the introduction of its battery electric locomotive. The company has been testing its battery powered locomotive in conjunction with BNSF for approximately a month and will continue to do so through March 2021.

BNSF Railway Company and Wabtec’s exploration of the future potential of battery-electric locomotives crosses another significant milestone as they begin testing the technology in revenue service between Barstow and Stockton, California. As BNSF seeks ways to further reduce its environmental impact, the advancement of battery technology offers some possible solutions.

“We've got everything in place and we're ready to see how this next-generation locomotive performs in revenue service," said John Lovenburg, BNSF vice president, environmental, in a statement. “BNSF is focused on continuing to reduce our environmental impact, and we’re committed to doing our part to test and assess the commercial viability of emerging technologies that reduce emissions.”

The battery-electric locomotive pilot program is part of a $22.6 million grant awarded to BNSF and the San Joaquin Valley Air Pollution Control District from the Zero- and Near Zero-Emission Freight Facilities (ZANZEFF) project by the California Air Resource Board to pilot several emissions-reducing technologies in and around railyards. The ZANZEFF project is part of California Climate Investments, a statewide initiative that puts billions of Cap-and-Trade dollars to work reducing greenhouse gas emissions, strengthening the economy and improving public health and the environment — particularly in disadvantaged communities.

Meaningful difference

The Wabtec battery locomotive is projected to provide operators with 10-30% in fuel savings, which could prove significant since fuel is the second largest operating cost of the class, costing roughly $7 billion per annum. Of course, the exact savings will depend on the grade of the track and the standard deviation, according to Wabtec CTO Eric Gebhardt.

The ability to leverage regenerative braking is crucial. "Today, most locomotives use what's called dynamic braking where you use traction motors as the train brakes. The battery electric locomotive takes the energy created by those traction motors to charge the batteries just like you would do on a Tesla or any other electric vehicle today," Gebhardt tells IndustryWeek. "This helps with the overall fuel savings because you're making your own power by braking while you're driving the train."Staying smart

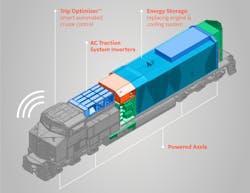

Wabtec and BNSF are running the tests with a consist sporting the all-electric locomotive sandwiched between Tier 4 locomotives, creating an environment that regenerate electricity to optimize fuel efficiency. Wabtec combines this consist with its trip optimizer software overlay, which essentially serves as a smart cruise control system.

"It knows what the track is, and what's coming ahead including the grades as well as when the turns are going to happen. This allows it to optimize the use of both the Tier 4 engines, as well as how to charge and discharge the battery electric locomotive,” Gebhardt says. “It is really a supervisory system allowing trains to operate as intelligently as possible, optimizing the way the energy is utilized across the entire consist.”

Wabtec is also working to ensure the right charging infrastructure is in place. However, the next step is finding those core customers ready to productize the offering and move it out into their fleets. Of course, finding the right routes will drive the most cost-effective results. "We want routes that have the right grades and standard deviations to fully optimize the dynamic braking capabilities. There are many tracks in North America where this makes economic sense,” he says. “And, depending on the length of the runs and the total megawatt hour of power necessary, there may be shorter runs that could be done in an EV only fashion. There may also be opportunities in mining applications where an all-battery situation makes sense as well.”

Riding the rails

Wabtec has every intention of constantly evolving its battery electric locomotive offering. The current configuration has a battery capacity of 2.4 megawatts. However, plans are in place for the next generation to go to six megawatts.

Ongoing battery evolutions will undoubtedly make a meaningful different. “If you look at batteries today the estimated learning curve going forward is 18%,” he says. “And, the energy density has also improved meaning you can put more batteries on the same locomotive."

Also, while the initially the focus is on the new production, Wabtec understands that locomotives are long lived assets, often having 25 plus year lives. With that in mind, the company will most likely look at retrofits for existing locomotives in the future, adding battery systems while leveraging the rest of the electronics, traction motors and other key pieces of equipment already in place.

Bottom line: There is a bright future ahead for the electric locomotive. “We are really just scratching the surface,” says Gebhardt.

About the Author

Peter Fretty

Technology Editor

As a highly experienced journalist, Peter Fretty regularly covers advances in manufacturing, information technology, and software. He has written thousands of feature articles, cover stories, and white papers for an assortment of trade journals, business publications, and consumer magazines.