While supercomputing capabilities are still quite rare, the touted growth of quantum computing should serve as encouragement for today’s digital manufacturers. After all, access to advanced computing has the potential to unearth new efficiencies and enhance operational methods.

GE Research, the central technology development arm for GE, was recently awarded access to the world’s #1-ranked supercomputer to discover new ways to optimize the efficiency of jet engines and power generation equipment. The U.S. Department of Energy (DOE) selected the GE project among 47 winners in the 15th year of its Innovative and Novel Computational Impact on Theory and Experiment (INCITE) program. This competitive and peer-reviewed program grants time for advanced science and engineering projects to harness the power of some of the nation’s most powerful supercomputers.

National Labs, such as Oak Ridge, Argonne and Sandia rely upon high-performance computing (HPC) assets to analyze, model, simulate and predict complex phenomena critical to the DOE missions. The department’s Office of Science supports and advances these practices through the Advanced Scientific Computing Research (ASCR) program, which oversees supercomputers such as Summit, hosted at the Oak Ridge Leadership Computing Facility (OLCF). ASCR established the INCITE program to accelerate scientific discoveries and increase the nation’s competitiveness by making DOE supercomputing resources available to top researchers in academia and industry..Michal Osusky, the project’s leader from GE Research’s Thermosciences group, says access to the supercomputer and support team at OLCF will greatly accelerate learning insights for turbomachinery design improvements that lead to more efficient jet engines and power generation assets, stating, “We’re able to conduct experiments at unprecedented levels of speed, depth and specificity that allow us to perceive previously unobservable phenomena in how complex industrial systems operate. Through these studies, we hope to innovate new designs that enable us to propel the state of the art in turbomachinery efficiency and performance.”

Osusky noted that industry partnerships with the National Labs can go a long way in reaching shared goals around sustainability. He cited past advancements GE has made with the Labs that have led to significant improvements in combined cycle power plant efficiency, wind energy output and jet engine performance, among others.

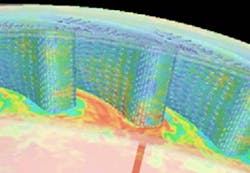

Researchers at GE also utilize company-internal supercomputer resources to support a wide array of advanced research initiatives for GE’s Aviation, Power and Renewable Energy businesses. Highly complex computational fluid dynamic simulations can be run to understand how the to achieve more optimal designs for GE’s broad array of turbomachinery products.

On this project specifically, Osusky and a team of engineers from the Research Lab and GE’s Aviation business will investigate the complex flow physics that impact gas turbine performance using newly-advanced Large Eddy Simulations (LES) on full 3D engine components. The team will look at the phenomena of flow mixing, boundary layer transition, separated flows, multiscale flow structures, and coupling between high pressure turbine components.

In addition to discovering ideas for more optimal turbine designs, the GE team also hopes this study leads to novel methods to integrate advanced 3D part and component designs that would deliver further efficiency and performance improvements.

About the Author

IW Staff

Find contact information for the IndustryWeek staff: Contact IndustryWeek