Survey Says: Additive Manufacturing on the Rise

Essentium recently released the findings from independent global research on the current and future use of industrial 3D printing. Simply put, acceptance across all industries is growing. And the key to continued growth is crystal clear: manufacturers desire an open ecosystem.

Although closed systems have been in the norm across industrial additive manufacturing - often locking manufactures into one vendors’ hardware, processes and materials - survey results show that the vast majority of executives see openness as crucial to advancing 3D printing at scale.

Manufacturers are now demanding open ecosystems to overcome system inflexibility and use the materials of their choice with 50% of respondents saying they need high quality and affordable materials to meet the growing demand for industrial 3D printed parts. While 85% of manufacturers reported that industrial-scale additive manufacturing has the potential to increase revenue for their business, 22% said vendor lock-in has hampered needed flexibility.

An open additive ecosystem will see more partnerships focused on giving customers greater control of their innovation, more choice in materials and industrial-scale production at ground-breaking economics. “Being locked into proprietary solutions that limit flexibility and choice is no longer an option if 3D printing is to become a serious contender as an industrial process for end-use products,” says Essentium CEO and Co-founder Blake Teipel. “An open market focused on developing new materials and better and faster machines is the only way for manufacturers to unlock new applications and new business opportunities. With this approach, the future belongs to the customer, not to the OEM.”

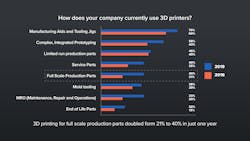

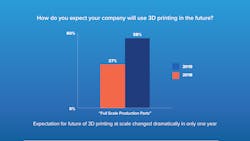

Fortunately, as technology obstacles around economics, scale, strength and speed of production dissipate, the number of manufacturers using 3D printing for full-scale production rather than just prototyping has almost doubled when compared to last year (40% in 2019; 21% in 2018). Additionally, two-thirds of companies reported they have more than doubled their use of industrial-scale AM in their manufacturing, and 47% are now using the technology for runs of thousands of printed parts, a jump of 17% compared to 2018.

Digging deeper

While reduced manufacturing costs remain a key driver for many manufacturers (58%), the need to improve customer response time is also fueling interest in additive technologies with 61% of respondents are adopting the technology to reduce lead times.

Teipel tells IndustryWeek, “Manufacturers are realizing more value from their systems because of open architecture. When companies install a system and have the ability to use more materials, they can quickly realize more value from their hardware investment and have the opportunity to achieve scale,” he says. “This is driving the strong appetitive for an open ecosystem where those within manufacturing can fully control the process. They also need the economics of time to part and the ability to deliver the ROI necessary when adopting these technologies.”

About the Author

Peter Fretty

Technology Editor

As a highly experienced journalist, Peter Fretty regularly covers advances in manufacturing, information technology, and software. He has written thousands of feature articles, cover stories, and white papers for an assortment of trade journals, business publications, and consumer magazines.