Turbulent times often bring out the best in our people and our efforts. The history of manufacturing is rich with examples of great leaps forward that have come in times of great challenge. Change, inspired by critical needs and constraints, unfolds in different ways, sometimes by design, and sometimes on demand. Strategic teams power a lot of change.

How we organize people for growth, performance and change is important. Structures and approaches to manufacturing talent must evolve to reflect the need for technical, analytic, creative, resource, solution and relational competence across the span of operations. We have coined the term “talent blocks” in a framework describing these six areas of human capacity. Talent blocks are critical human assets in manufacturing. They help shape key elements of business readiness, performance, resolve and sustenance.

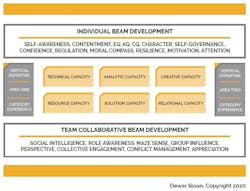

But there is more. People work together best when they are served with the experience and expertise of others. People are more readily engaged when their interactions are shaped by positive culture, attitudes, character, connections and respect. These are part of what we call “talent beams” in the framework, and they reflect across the influences and behaviors that surround the interactions of people at every level. Talent beams serve and enable the individual and collective efforts of people working across the manufacturing realm.

The chart below shows the framework of six Talent Blocks surrounded by a pair of Horizontal Talent Beams, and a set of Vertical Talent Beams. The horizontal beams represent individual and collective awareness, social and cultural attention, character, and influence. The vertical beams represent career expertise and experiences at two levels, from the earlier stages of exposure to the more seasoned stages of development in a person’s industrial work spans and roles. Some organizations refer to the importance of Emotional Intelligence and Adaptive Intelligence as part of the “soft skills” balance of individuals and teams. These are part of Talent Blocks and Beams.

Change Viewed through Strategic Lenses

Changes in manufacturing are often tied to smart automation, advanced supply chain leverage, adaptive capacity, operational excellence, agile practice, process integration, Industry 4.0, and system innovation. Companies must look ahead to prepare, engage and advance across a changing business landscape. We need manufacturing teams to be ready, willing, and strong. Leading with the right people, shaped with the right talent blocks and beams, matters greatly.

Talented organizations frame planning, make decisions, manage risks, and solve problems. Talented individuals and their teams drive the creation of new strategic and economic value. Competitive advantage in manufacturing reflects in strategic, workforce and cultural terms, and strategic teams provide the “change agency force” that powers real manufacturing advantage.

The Work to Be Done Across Manufacturing

The work to be done in manufacturing entails many things, most of which reflect important strategic and economic goals. We can look at these efforts and objectives in terms of the organization’s business model. We can also examine key elements of operational excellence in the context of market requirements and competitive conditions. And then, we can look at innovation maps as part of what we might expect to unfold in the future of the enterprise.

Manufacturing involves broad and complex challenges, shaped by issues of compliance, integration, coordination, and experiments. Some organizations have the span and depth to tackle everything, all the time, in every setting, with conventional structures and exceptional talent blocks and beams. However, many organizations need a different approach, one that is powered by strategic teams of different kinds and forms. These teams can greatly enhance the abilities of manufacturing systems and operating units. People with unique talent blocks and beams can join together with abilities to engage, perform and learn in action. Strategic teams are alternatives to bulking-out organizations with more structure and weight. They have many advantages, and they are, by definition, adaptive. They work in large and small organizations alike, and they are well-suited to continuous improvement and change management.

Moving the Needle with Strategic Teams

From experience with many industrial organizations, we have framed a collection of 20 kinds of strategic teams. These teams shape effective collaboration, critical analysis, creative exercises, problem solving, system improvement, and much more. Strategic teams operate with specific charters that tend to run on short time frames and rapid work cycles. Their purpose is to create new strategic and economic value. They drive insight and interaction for progress and impact.

Some examples here are useful. We find two particular strategic teams to be helpful across a broad range of manufacturing settings. First, we have “advance teams” which are equipped with talent blocks and beams that are well-suited for exploration and discovery. Managers put together these advance teams to provide forward assessments, build new points of view, conduct experiments, develop roadmaps, define and redefine requirements, review constraints and decipher specific options.

Advance teams help engage readiness and shape confidence. One manufacturer of agricultural systems and technology uses advance teams to explore opportunities for project collaboration between operating groups in different plant locations. They work on supply chain integration, production concentration, production and process innovation, data-driven automation/control and a number of manufacturing experiments that are associated with Industry 4.0 themes.

Second, we have “red/gray teams” which also have a number of applications. Managers charge red/gray teams with the work of testing assumptions about planning, and reviewing decision options, risk factors and problem sets. These teams assemble people whose talent blocks and beams are well-matched for comparative analysis, strategic and operational stress-testing, and scenario investigation. They can identify the weak nodes and links across the organization’s value streams. Red/gray teams can also be used in simulations for offensive and defensive plan review.

Red/gray teams bring focus and resilience, and they help create new manufacturing paths. One producer of construction components and systems uses red/gray teams to evaluate new design-for-manufacturing and design-for-application options. Exercises like these help people better understand what kind of operational and service choices make sense. This kind of work often reveals opportunities for product and service development and operating partnerships.

Enhancements, Engagement, Experiments

Strategic teams provide a very strong learning and development base for talent blocks and beams, building the mindset for effective collaboration and operational excellence. Strategic teams can work as laboratories for new manufacturing systems, value stream models and Industry 4.0 test flights. The bottom-line impact of strategic teams should always be part of their charter and orientation. How will these teams shape revenue and resource leverage? How will they drive growth, performance and change?

Strategic teams and readiness

Manufacturers depend on system effectiveness, process efficiency, standard work, adaptive capacity, integration, speed, agile practice, and moves that make them more competitive. Strategic teams are a key element in the journey of business transformation. Let’s reflect on these things in our everyday conversations. Where could a strategic team help us tackle the changes needed in our manufacturing model? Where could a strategic team help us bridge the gaps between plant functions, supply chains, network capacity, profit models and operations? How could strategic teams enhance our competitive position, both near-term and long-term? Strategic teams are formed in talent blocks and beams. These teams become the agents of manufacturing performance and transformation. They are part of the relative advantage of manufacturing that companies depend upon for growth, performance and change over time.

Daniel Wolf leads the strategy and governance practice of Dewar Sloan, an executive and board advisory group serving the broader growth, performance and change interests of organizations. His latest book is Strategic Teams and Development, a field book for strategic teams in action.

Joshua Lord brings a portfolio of technical, organization and project management insights to the Strategic Teams and Development practice of Dewar Sloan. Josh conducts research initiatives and guides strategic team programs, communication programs, and program development.

About the Author

Daniel Wolf

President and CEO, Dewar Sloan

Daniel Wolf leads the strategy and governance practice of Dewar Sloan, an executive and board advisory group serving the broader growth, performance and change interests of organizations. His latest book is Strategic Teams and Development, a field book for strategic teams in action.