Bridging the Skills Gap: Best Practices for Finding, Keeping and Growing Talent

A shortage of trained, educated workers is forcing the manufacturing industry to change how it finds and retains talent. A survey of manufacturing executives by the Manufacturing Institute and Deloitte ranked access to a highly skilled, flexible workforce as the most important factor in their success -- 20 percentage points higher than other factors, such as new product innovation or increased market share.

Against these challenges, manufacturing companies need new ways to build and retain not only qualified engineers and welders, but positions that involve the day-to-day use of their products, such as maintenance technicians. This development and retention of talent is vital for achieving long-term success in the industry and for accommodating the demands of a strengthened economy.

In recent decades, all areas of manufacturing have suffered from the skills shortage. The challenges are varied: advancements in technology, lack of education and applicable skills training in educational curricula, an aging workforce, and a lack of interest in manufacturing jobs.

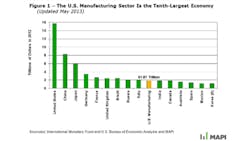

Despite the skills gap, growth in manufacturing remains strong. According to the Manufacturing Institute’s Facts About Manufacturing, taken alone, the manufacturing sector would rank as the world’s 10th-largest economy, ahead of nations such as India, Canada and Korea. Manufacturing contributes $1.8 trillion to the American economy each year, and it can do more. That depends on manufacturers and their vast networks investing in aggressive recruitment and training efforts for the next generation of manufacturing talent.

Education: Keeping Up with Technology

With advances in technology, it’s often difficult for educational curricula and training programs to keep up. That contributes to the labor force gap. In response, many manufacturers are taking a hands-on approach by getting involved with local tech, trade and high schools. By building relationships with school leaders and instructors, companies can shape programs to ensure relevant skills are being taught to future workers. These types of relationships can offer the potential for direct recruitment of the highest-quality talent.

At the high school level, some companies are partnering with career development centers to mentor students through manufacturing apprenticeship programs. For example, The Raymond Corporation lets juniors and seniors explore career options in the material handling industry through apprenticeships. The students get a firsthand look at the intricacies of manufacturing, including workflow process, quality improvement and material handling. Upon completion of the program, Raymond holds an apprenticeship night where students share what they’ve learned. Attesting to the program’s success, Raymond has hired many participants as full-time employees at its headquarters.

Once the talent comes through the door, companies need to prepare them for success. Training and educating employees internally is key. Raymond requires new employees to spend at least three days in orientation to introduce them to the company’s philosophy, policies, benefits and training programs. Some employees require additional training or orientation based on the specific position they’re hired into. For example, Raymond puts many welders in an apprenticeship program where they are able to learn additional skills beyond their initial training program.

Raymond also provides additional education sessions throughout the year, including some that employees and managers can choose to attend and others that are required based on their role. These programs offer the opportunity to learn, grow and succeed. They also allow workers to refine their skills and keep up with industry changes.

Manufacturers invest in training and educating so they can make quality products for dealers and technicians to sell and support. For many industrial companies, dealers and teams of technicians often are the day-to-day contact point for consumers. Companies rely on them to represent the product. The education and training provided for these individuals is vital to the success of any manufacturer.

Service technicians for Raymond products go through practical application training so they can immediately work in the field. Through training, technicians learn the mechanical, hydraulic and electrical systems on our trucks. In turn, customers get better service. Employees can confidently diagnose problems and find solutions.

The Aging Workforce

Another big contributor to the current skills gap is the aging North American workforce. Workers are rapidly reaching retirement, which is widening the generational skills gap in manufacturing. The percentage of the American population older than 50 is expected to surpass 35% in 2020, according to the U.S. Department of Labor, Employment and Training Administration. In 2000, that figure was 27%; in 1900, it was 13%.

Currently, the fastest-growing segment of the labor force is Americans ages 55 and older. As baby boomers approach retirement and the nature of manufacturing jobs change, there’s an even greater need for skilled workers. That’s why manufacturers need to keep qualified talent coming through the door and advancing in the company.

In addition, with a decline in rigid assembly processes and a change to more automated processes, the success of the manufacturing industry rests on recruiting workers who have the skills and education to flexibly move from one activity to another, and who can operate technologies designed for rapid changes and quicker procedures. On the sales and service side of manufacturing, management as well as sales and marketing skills are in short supply. This side of the business begs for well-educated, adaptable and knowledgeable workers.

Retaining Talent

At the other end of the spectrum are younger workers. It’s vital to retain manufacturing talent. Think about why people younger than 35 leave manufacturing jobs. At the top of the list is the feeling that they don’t have a future at the company. Younger employees want to know they are meeting expectations, providing value and worthwhile. Employee appreciation is often neglected but is absolutely necessary. Offering ongoing educational programs not only helps employees improve and feel invested but allows company leadership to share know-how.

It also helps to reward employees for a job well done. For example, Abel Womack, a Raymond Sales and Service Center based out of Lawrence, Mass., gives gift cards, T-shirts and a letter of congratulations to new employees who have achieved 90 days of excellent work. This “success package” might seem like a small gesture, but it goes a long way to make employees feel appreciated.

Keep in mind the value of taking time to speak with employees one on one. See how they are progressing. Give them a chance to share successes, concerns and questions. Many companies are concerned about a loss in productivity because of meetings. But think about the cost of turnover and retention.

The Raymond Corporation has each of its executives conduct regular lunch meetings with a small cross-functional group of employees on a regular basis as one of its methods of improving communication and keeping the executive group in touch with all areas of the business. Of all the things manufacturers can do to improve employee retention, staying committed to employees and showing sincere interest in them pays off.

Many companies are working to accommodate aging workers who are nearing retirement age and have devoted their careers to the manufacturing industry. For example, Abel Womack recently rolled out a new program designed for technicians to optimize its scheduled maintenance procedure. Workers focus on key principles that reduce strain and fatigue and improve consistency and quality. As a result, technicians report feeling better about their jobs and their ability to share knowledge and expertise.

Raymond Handling Solutions, another Raymond dealer based in Santa Fe Springs, Calif., is working to place senior-level technicians in positions that are less physically demanding. This allows these valuable, knowledgeable employees to continue working and encourages younger employees to advance into new positions.

Recruitment Efforts

So how do companies find the next leaders from a shrinking talent pool? It’s simple: through innovation. Integrated and proactive recruitment practices may include the following:

According to the study by the Manufacturing Institute and Deloitte, 67% of U.S. manufacturers are facing a moderate to severe shortage of qualified workers, and as many as 600,000 jobs remain vacant due to the shortage. To produce, sell and support a quality product, it is vital to address this issue and take the necessary steps to not only get skilled workers in the door but keep them there. Investing in education, training and retention efforts is fundamental and necessary. Confronting this issue head-on and incorporating these best practices within manufacturing operations will improve business and ensure quality representation of companies’ products and services, thereby strengthening their brand and market share.