In the design of manual (unpaced) production lines, there are a number of issues to be considered if performance is to be improved. The operators on each station along the line work at different rates from each other, and an individual can vary in the speed at which he or she works; and so where to place these operators along the line is an important consideration. As well as this, the length of the line, or number of workstations plays a role, as does the size and position of buffers where partly completed pieces are placed awaiting treatment in the next step of the process.

People Can't Work at the Same Pace All Day

The variation in the time taken by an operator to complete a task may vary quite considerably. People in general cannot perform a task or a series of tasks differing in complexity and specificity again and again at exactly the same speed over a length of time, and research has shown that the average time to complete a task can vary by up to 66% in a day. This variation can be measured using the coefficient of variation (CV) (CV = standard deviation/mean), which is commonly used in simulations to estimate where best to place operators with different variations in their average task-completion time.

Where Should Buffer Space Go?

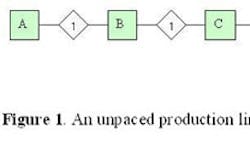

Another influence on the performance, as mentioned earlier, is the buffer size and placement. In theory, the best way to allocate buffer space along the line is evenly as shown in figure 1. However this is not always possible for technical reasons and a manager may have to distribute buffer capacity unevenly. This has long thought to be a disadvantage in terms of performance, but some research shows that with correct "uneven" placement of buffers between stations, performance can be maintained, and even enhanced.

Figure 1 shows a 5-station serial line with 4 buffers, where the squares portray the stations and the diamonds depict the buffers:

The variation in individual task-completion times and uneven buffer distribution along the line means that the line is "unbalanced" i.e. we don't have a series of stations completing tasks at the same pace, with a fixed and equal buffer capacity between the stations.

Performance Measures

There are different ways of measuring how efficiently a line is working. The two measures that were used in this study were the total idle time-the (IT) % i.e. the fraction of time that the line is not working to total working time, and the average buffer level (ABL) for the whole line. Evidently the goal is to reduce idle time and make sure the line is functioning as smoothly as possible, and also to reduce average buffer levels, keeping the quantity of unfinished items in the buffers as low as we can.

Line Designs for Simulation

The mean operation times for each of the stations along the line are fixed and the same, but the buffer sizes between the stations and the coefficients of variation of the operation times of the stations are different. Figure 2 illustrates some of the patterns investigated for a five-station line.

Five-station lines were simulated with a total overall buffer capacity (TB) of both 8 and 24 units, distributed unevenly along the line; and eight-station lines were also simulated with total buffer capacities of 14 and 42 units. Both line lengths corresponded to mean buffer sizes of respectively 2 and 6 units. The pattern that gave the best results was also simulated with a TB of 16 and 28.

The stations were arranged in four ways according to the coefficient of variation. Figure 3 illustrates these four policies.

Figure 3a shows the policy where the stations with lower and higher variability are placed one after the other in a zig-zag shape. For the bowl shaped pattern (3b), the workers with low variability placed in the middle of the line with the more variable operators at both ends of the line. The inverted bowl shape is the opposite of this, with station operators of higher variability in the middle (3d). The "chaise longue" pattern (3c) has operators going progressively from high to low (and from low to high) variability along the line.

For each of the patterns above, the buffer capacity was distributed along the line in the arrangements illustrated in Table 1.

The configurations used include concentrating the buffer capacity towards the end of the line (A) or the beginning of the line (C), by placing more buffer capacity towards the middle of the line (B), a peak before the end of the line (D1), alternating high and low buffers in a zig-zag (D2), or a bowl shape with lower buffer capacity in the middle of the line (D3).

The results showed that there was no general policy that gave improved or worse performance than the others broadly speaking, but some particular patterns within the policies produced considerable savings in idle time or in average buffer levels compared to the balanced line.

Idle Time Results

The best results in terms of idle time were obtained with the combination of CV pattern 4 (a bowl shape) and the buffer arrangement C with more buffer capacity concentrated at the beginning of the line.

Good results are also seen when the buffers are placed in a bowl shape (D3) and combined with the bowl shaped CV patterns 4 and 5, and also the zig-zag pattern 3. This might make us think that a good option, then, might be to put lower buffer capacity in the middle of the line as a general rule. However, when combined with pattern 8 where the CVs are in an inverted bowl-shape, we get the worst simulated pattern. So we cannot say that there's a particularly "best" arrangement for buffers in general.

In addition, the patterns where the CVs are disposed in a bowl shape (patterns 4 and 5) provide consistently good results whatever the buffer placement is.

Average Buffer Level Results

The best results were found for the combination of CV pattern 4 (bowl shaped) and buffer arrangement A (concentrating the buffers towards the end of the line).

Other good patterns were bowl shaped pattern 4 arrangement of CVs combined with buffer arrangement B in an inverted bowl-shape, and the chaise longue pattern 6 arrangement of CVs combined with buffer arrangement A.

The Savings Generated

The calculations of how much idle time and buffer levels are changed are done in comparison to an "ideal" balanced line where all the stations work at the same pace, and buffer capacity is evenly spread along the line. Table 2 shows the changes calculated in percentage terms with a negative sign indicating a reduction and a positive sign an increase in idle time (IT) or average buffer level (ABL).

What Decision Should be Made?

A line manager is going to have to opt for a line where the greatest advantages can be had. It may be to reduce idle time should it be costly, for instance in an industry where demand is high and operators are working full out such as on the assembly or production lines in consumer goods (toys, shoes, office supplies), or where manpower is expensive. In these cases, where any idle time leads to great expense, the best or other favourable jointly unbalanced CV and buffer size designs will be selected to get the largest possible idle time reduction.

It may be, however, that the principal aim is lean buffering, like in the automotive industry, where just-in-time management requires it. Here, the best or some other advantageous unbalanced patterns which bring average buffer levels down would be the most appropriate

Conclusion

Bearing in mind that the nominally balanced line has generally been believed to be an "ideal" line, it is quite interesting that distributing operators with different variations in operating times into carefully selected positions, and placing buffer capacity with care along the line can lead to results which at worst are an improvement on just randomly placing them anywhere, and at best actually outperform the balanced line. The savings generated can be considerable when we look at the figures in table 2, and managers might well consider moving away from a balanced line towards a deliberately unbalanced line in view of these results.

It should not be forgotten, though, that there are numerous possibilities for unbalancing the line in the "wrong" way, which could lead to undesirable results, i.e. increases in average buffer levels and/or idle times.

In spite of this, however, the scale of the potential reductions in idle time (31%) and average buffer levels (nearly 78%), when calculated over the lifecycle of a production line means that purposely unbalancing the buffer sizes and operators with different variabilities could lead to real benefits for the manufacturer and so might be a strategy to take into account when designing the production line.

Sabry Shaaban and Sarah Hudson are in the Department of Finance and Operations, and Department of Management and Organization at the Rennes International Business School located in Rennes, France. To contact them via email: [email protected] [email protected]