Supply chain leaders at manufacturing companies are increasingly likely to have a seat at the executive table, according to a survey from Tompkins Supply Chain Consortium. Roughly half (51%) of the manufacturing companies surveyed have a supply chain leader at or above the executive vice president level, with the apparel and automotive companies leading the way among those surveyed at 100%, while 57% of food & beverage companies acknowledged having an executive vice president of supply chain, or what's known as a chief supply chain officer (CSCO).

"With supply chains becoming more dynamic and agile, organizations need to able to keep up with the pace," says Bruce Tompkins, executive director of the Consortium and author of the study. "And these companies are beginning to realize the significance of having a high-level supply chain executive influence their business strategies."

There are, however, sizable communication gaps within some companies, such as not having the supply chain group involved in setting inventory targets. And though it's a relatively small percentage, 14% of manufacturers surveyed say they do not have a formal process for aligning their supply chain goals.

"These gaps in goal alignment indicate significant opportunity for better communication and integration of supply chain functions," Tompkins says. "However, companies are discovering these opportunities for improvement, and there is an increasing trend toward resource sharing across divisions and business units."

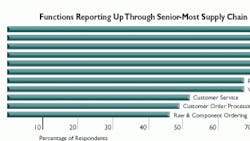

Based on the survey, such tasks as transportation execution, warehousing and distribution center (DC) operations, supply chain network design and planning functions are now typical responsibilities for a CSCO (see chart).

- Supply-demand-finance balancing is critical. Supply chain executives need to be involved at various levels in the operations, including demand forecasting, constrained supply chain planning, predictive modeling and risk management.

- Outsourcing is creating new supply chain dynamics -- time and speed are critical. CSCOs are planning and forecasting more frequently, with four out of five making major updates to forecast at a frequency less than or equal to a month, while 77% make major updates to supply plans at a frequency less than or equal to a month. This increased frequency is directly due to a corresponding increase in uncertainty and lack of visibility due to outsourcing. As a result, companies are trying to perform constant planning and re-planning.

- Create a chief supply chain officer or similar role. If you don't already have somebody with a CSCO role, get one, the Abedeen study recommends. This will help provide the strategic impetus that supply chain needs within a company.

See Also:

About the Author

Dave Blanchard

Senior Director of Content

Focus: Supply Chain

Call: (941) 208-4370

Follow on Twitter @SupplyChainDave

During his career Dave Blanchard has led the editorial management of many of Endeavor Business Media's best-known brands, including IndustryWeek, EHS Today, Material Handling & Logistics, Logistics Today, Supply Chain Technology News, and Business Finance. He also serves as senior content director of the annual Safety Leadership Conference. With over 30 years of B2B media experience, Dave literally wrote the book on supply chain management, Supply Chain Management Best Practices (John Wiley & Sons, 2010), which has been translated into several languages and is currently in its second edition. He is a frequent speaker and moderator at major trade shows and conferences, and has won numerous awards for writing and editing. He is a voting member of the jury of the Logistics Hall of Fame, and is a graduate of Northern Illinois University.