So That Happened: Younger Workers Willing to Consider Manufacturing Jobs

Editor’s note: Welcome to So That Happened, our editors’ takes on things going on in the manufacturing world that deserve some extra attention. This will appear regularly in the Member’s Only section of the site.

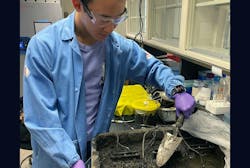

The Dirt on Microbial Fuel Cells

Anyone with a backyard garden knows the magic of microbes. Depleted dirt nourishes only weeds, but adding compost (biodegraded food waste, cardboard, leaves, etc.) generates black gold to grow Instagram-worthy vegetables.

Microbes generate energy that can be harnessed for other uses, too.

Researchers at Northwestern University are experimenting with a soil-powered fuel cell that harvests energy from microbes. The power is used to run sensors that collect agricultural data.

The fuel cell is about the size of a paperback, and it even has a tiny antenna that transmits data (squeee!). Researchers hope the microbe-powered cell could be a low-powered data-collection option for farmers and scientists that’s inexpensive (no rare-earth minerals needed), environmentally friendly and low-maintenance.

“We’re not going to power entire cities with this energy,” George Wells, an associate professor of civil and environmental engineering and a lead researcher on the study, told Northwestern News. “But we can capture minute amounts of energy to fuel practical, low-power applications.”

Microbial fuel cell technology dates back to 1911, but the results have been weak. The Northwestern team tweaked and streamlined past designs to improve airflow and moisture collection and use accessible materials. Their prototype generates 68 times the energy needed to power its sensors.

It’s still early days, but microbial fuel cells, like the soil in Cleveland around late March, are showing signs of life.

—Laura Putre

Industrial Metaversing at CES 2024

CES 2024 has come and gone and while the cavalcade of new headphones and televisions don’t apply very much to IndustryWeek, there was one XR-related announcement of note. Siemens and Sony have partnered up to help bring the industrial metaverse to life by pairing up a new, as-yet-unnamed Sony XR rig with new Siemens software called NX Immersive Designer.

It’s a digital twin play focused on prototyping and product simulation that also gave Sony a way to generate buzz for its new headset, called a “spatial content creation system.” Sony’s new hardware will be released sometime this year.

So, while one of the experts we consulted for this year’s manufacturing technology predictions story said everyone was moving away from talking about the industrial metaverse, Siemens and Sony are holding on to the idea for a bit.

—Dennis Scimeca

Infrastructurally sound

Manufacturers producing for infrastructure projects are in a pretty sweet spot these days: Witness about 85% of survey respondents telling our sister brand Roads & Bridges they expect 2024 will be good or better. And the money now beginning to flow into state and local budgets will only grow in coming years.

That last point was a key message (re)delivered by the leaders of 13,000-employee Commercial Metals Co., which specializes in steel rebar and which last week provided some of the first industrial data points of this earnings season.

“Remember, the way the [Infrastructure Investment and Jobs Act] program is structured, every year there’s a grant, but it doesn’t necessarily mean that the spend in that year is the same,” President and CEO Peter Matt told analysts. “Over the course of the program, we believe you’re going to see kind of an escalating level of spending.”

Which means the numbers could become rather eye-popping in the vein of those for commercial construction, which are being goosed by stimulus investments in chip and battery plants. Matt said his team is seeing an average budget increase of about 15% for state transportation departments. More broadly, he noted, Dodge Analytics data shows the number of infrastructure projects in the pre-design and design stages late last fall were up, ahem, tenfold from a year earlier.

—Geert De Lombaerde

Hertz Dumping EV Fleet? Good Riddance

Barely two years after announcing it would invest heavily in Tesla Model 3s and other electric vehicles, rental-car giant Hertz is shrinking its EV fleet and dumping about 20,000 Teslas on the used-car market. Good. It was a stupid experiment with predictably bad results.

To be clear, I’m an EV owner and think driving electric makes sense for many if not most typical daily drives. I charge my car at home, drive to and from work and run errands with no fear of running out of power. I can even take the occasional short trip out of town with no anxiety over range. All of that is easy for me because I know there’s a reliable charger in my garage, and I know roughly how many miles I’ll be driving in a day.

That’s absolutely not the case with rental cars.

If I fly into a city and rent a car to drive for business, I typically don’t know if my hotel is going to have EV chargers available, or if they’ll be the appropriate chargers for that vehicle. And, while I can map out where and when I’ll be driving to meetings and such, I wouldn’t typically map out a route that includes stops at charging stations, based on the expected charge of the vehicle. If I were planning on renting an EV, I could do that, but here’s the second part of what Hertz did incredibly badly.

At a recent family gathering, a cousin of mine rented a vehicle from Hertz, and they gave him a Tesla to use. He didn’t request an EV, that’s just what they had available that day in Atlanta. He didn’t even know the car was electric until he got to the hotel about an hour away and started getting low-charge alerts (yes, Hertz gave him an EV with less than half a charge and no notice on what to do about that). The hotel didn’t have a charger, and there were no charging stations within 20 miles of our location. So, Hertz sent a tow-truck for the Tesla and a gasoline-powered SUV for my cousin.

This wasn’t a failure of technology, it was a failure of business models and use cases. Hertz badly dropped the ball on employee education (rental desk people should have been trained thoroughly on making sure customers knew what they were getting and how to plan around using an EV). But, even if they’d gotten that part of the puzzle right, rental cars are a poor use case for EVs at the moment. Until there’s a charging network as extensive as the existing gas station network, renting an EV will require motivated renters who are willing to suffer some inconveniences.

The silver lining in all of this, there will soon be a large number of used Tesla models available for purchase. So, commuters willing to charge at home will soon have some lower-cost EV options, potentially expanding the number of electric cars on the road.

—Robert Schoenberger

Invisible Backbone?

79% of Americans aged 35 to 44 are open to working in manufacturing, according to recent Soter Analytics research; the data was obtained through a survey of 1,000 U.S. respondents conducted in December 2023.

In this survey, the respondents were asked about their beliefs around the supply chain in 2024 and their willingness to work in industrial sectors like manufacturing, warehousing, last-mile delivery and construction.

More than half of Americans (54%) indicated willingness to work in manufacturing, while 32% are not open to work in the industry. The 16 to 24 age group and the 25 to 34 age group are similar in their openness to work in manufacturing, reporting 68% and 69%, respectively.

“What used to be the invisible backbone of the economy has come into the fold as a mainstream talking point amongst consumers,” says Soter Analytics CEO and Founder Matthew Hart. “2024 offers a major opportunity to rebuild these industrial sectors as they confront economic and social tensions, staffing challenges and a slew of additional stressors.”

—Anna Smith

Operations Leadership Summit Update

In June, IndustryWeek will be holding its first live, in-person event since 2022 in Indianapolis. The IW Operations Leadership Summit will gather plant managers, vice presidents of operations, department leaders and other professionals tasked with getting product out of factories.

We’re still in the process of picking speakers and identifying plant tours, but we’ve locked in a few sessions, which I can share now:

- Subaru of Indiana Automotive (SIA) will offer a tour if its Lafayette, Indiana, plant, and two of its manufacturing leaders will be offering a joint presentation on how the automaker applies continuous improvement practices on a daily basis and how it trains workers and leaders to prepare for future challenges. Speakers:

- Process Engineer Elizabeth Parra

- Automotive Technical Training Professional Jason Lipscomb

- GE Healthcare Senior Manager of Operations Sarah Tilkens will discuss how to optimize talent for operational excellence. Tilkens’ presentation will focus on the people side of continuous improvement, how to empower and retain the best people and offer advice on creating a culture of continuous improvement by focusing on people.

- Emerson Electric Director of Digital Factory Solutions Fabian Ochoa wants to talk AI and how new tools can improve manufacturing operations.

This is just the start. In the next few weeks, we expect to finalize the bulk of the show agenda as we choose from an extensive list of fantastic proposals from great speakers.

—IndustryWeek Staff

About the Author

Laura Putre

Senior Editor, IndustryWeek

As senior editor, Laura Putre works with IndustryWeek's editorial contributors and reports on leadership and the automotive industry as they relate to manufacturing. She joined IndustryWeek in 2015 as a staff writer covering workforce issues.

Prior to IndustryWeek, Laura reported on the healthcare industry and covered local news. She was the editor of the Chicago Journal and a staff writer for Cleveland Scene. Her national bylines include The Guardian, Slate, Pacific-Standard and The Root.

Laura was a National Press Foundation fellow in 2022.

Got a story idea? Reach out to Laura at [email protected]

Dennis Scimeca

Dennis Scimeca is a veteran technology journalist with particular experience in vision system technology, machine learning/artificial intelligence, and augmented/mixed/virtual reality (XR), with bylines in consumer, developer, and B2B outlets.

At IndustryWeek, he covers the competitive advantages gained by manufacturers that deploy proven technologies. If you would like to share your story with IndustryWeek, please contact Dennis at [email protected].

Robert Schoenberger

Editor-in-Chief

LinkedIn: linkedin.com/in/robert-schoenberger-4326b810

Bio: Robert Schoenberger has been writing about manufacturing technology in one form or another since the late 1990s. He began his career in newspapers in South Texas and has worked for The Clarion-Ledger in Jackson, Mississippi; The Courier-Journal in Louisville, Kentucky; and The Plain Dealer in Cleveland where he spent more than six years as the automotive reporter. In 2014, he launched Today's Motor Vehicles (now EV Manufacturing & Design), a magazine focusing on design and manufacturing topics within the automotive and commercial truck worlds. He joined IndustryWeek in late 2021.

Anna Smith

News Editor

News Editor

LinkedIn: https://www.linkedin.com/in/anna-m-smith/

Bio: Anna Smith joined IndustryWeek in 2021. She handles IW’s daily newsletters and breaking news of interest to the manufacturing industry. Anna was previously an editorial assistant at New Equipment Digest, Material Handling & Logistics and other publications.

Geert De Lombaerde

Senior Editor

A native of Belgium, Geert De Lombaerde has been in business journalism since the mid-1990s and writes about public companies, markets and economic trends for Endeavor Business Media publications, focusing on IndustryWeek, FleetOwner, Oil & Gas Journal, T&D World and Healthcare Innovation. He also curates the twice-monthly Market Moves Strategy newsletter that showcases Endeavor stories on strategy, leadership and investment and contributes to other Market Moves newsletters.

With a degree in journalism from the University of Missouri, he began his reporting career at the Business Courier in Cincinnati in 1997, initially covering retail and the courts before shifting to banking, insurance and investing. He later was managing editor and editor of the Nashville Business Journal before being named editor of the Nashville Post in early 2008. He led a team that helped grow the Post's online traffic more than fivefold before joining Endeavor in September 2021.