In a digitalized world, smart has become a bit of a catch phrase. Case in point: cars, household appliances, manufacturing environments and even cities are touted as smart. What makes these environments smart – and does it really matter?

What does smart mean? In a far too simple definition, it is the combined ability to create, collect, share and act on data.

Does it matter? Absolutely.

The competitive nature of today’s operations means even small efficiency differences can differentiate winners from losers. As a result, the trend toward smart is often at the center of any digital transformation journey within manufacturing. This is true for most, if not all, of the success stories making headlines.

Consider, for instance, the two Wabtec engine plants in Grove City, Pa. At every turn, Wabtec collects data within these operations to make smarter decisions in real time. Additionally, data collection continues once the product is out in the field using digital threads to constantly improve the company’s understanding of how engines are performing in the wild – a process that ultimately empowers its engineers to makes strategic modifications to products.Improving Connectivity

The ability to seamlessly and automatically collect, process and act on data that defines these smart environments does not just happen. This level of data collection requires a mix of sensors strategically placed to gather the right data. At the same time, connectivity is crucial for organizations to enjoy real-time visibility.

As such. connectivity will always be at the heart of any smart environment. After all, connectivity is what enables real-time data monitoring, predictive learning and a wealth of other use cases.

Recent advances in connectivity, most notably 5G, enable organizations to realistically take the next step. In addition to 5G’s deployment, the rise of private networks is quickly becoming a vital part of a converged network strategy, allowing manufacturers to drive digital transformation with a secure connectivity backbone separate from the public network, says Michael J. Zeto III, senior vice president, global strategy and emerging businesses at Boingo Wireless.

“Manufacturers need a converged network strategy with different types of connectivity to drive diverse use cases. Most will still need WiFi and WiFi 6 as well as private cellular, 5G and edge compute. The goal should be driving outcomes rather than focusing on what network to build. As facilities get smarter, it certainly will start to reap the rewards of downtime prevention,” Zeto tells IndustryWeek. “5G is finally ushering in the fourth industrial revolution, and by 2030, there'll be 4.7 billion wireless models across smart manufacturing environment. Smart factories are much more mobile with the ability to move connected equipment around without losing functionality. The private network becomes very important when adding in robotics and augmented reality use cases.”

Connectivity infrastructure continues to become more intelligent and more scalable. However, many private network proof of concepts deployments have shown the value of multi-access edge compute, which is decreasing the latency, increasing security and allowing far better data management. “We are still at the beginning of a journey for manufacturers,” Zeto says.

Elephant in the Room

Of course, not everything about going smart is rosy.

Even though smart functionality is now strategically built into most products and production equipment today, there are obvious costs associated with this array of digitalization efforts.

However, the biggest cost is not the price ticket attached to the smart purchase. Instead, it is the reality that digitalization opens the door to immense security implications. Data security is not a new challenge. However, the highly connected nature of today’s smart environments means everything is now at risk, and at a granular level never feasible before.

What does this mean? Beyond the costly financial data exposure that has crippled companies in past IT leaks, a cyber incident into an operational environment can mean losing control of vital production tools – equipment that by nature is heavily automated in some cases. It is not a pretty picture, and failure to properly secure these environments can prove devastating to any sized manufacturer.

The key to success here is to fortify security around operational technologies at each step of the way, embracing a zero-trust mentality, especially when bringing new connection points into the mix.

While most manufacturers understand that security is important, as operational environment become smarter, security needs to become a foundation part of the process – not something bolted on as an afterthought.

There is no individual security product or service that will fully protect a smart environment. Instead, strong security starts and ends with behaviors in alignment with proven best practices.

Adding to the Chip Conundrum?

There has never been a better time for organizations to embrace what digitalized smart environments can offer. After all, the data-fueled insights and visibility smart environment provide into production processes enables constant improvement as well as better decision making.

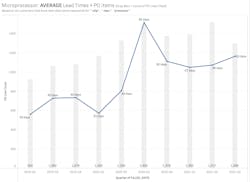

However, the smart movement intensifies the need for semiconductor chips, not only to fuel 5G connectivity requirements, but also to enable collection and processing capabilities.

Fortunately, efforts are underway to improve the current situation, including numerous chip manufacturers working to bring on new U.S. chip operations online. Even though these new facilities will take years before they are able to produce chips at a production level, the process of digitalization does not happen overnight either.

Part of being smart, means planning the rollout in accordance with ongoing supply issues. Although the ongoing chip shortage has hit home to basically every person in every market in every industry, the supply chain issues that have intensified since COVID are not new.

“They are being exaggerated by the change in demand – and more specifically the change of people's behavior really around the demand,” says Tom Kieley, CEO and co-founder of SourceDay. “Add in the Amazon effect of people wanting next-day, same-day delivery of every component they can get their hands on to, to ship their goods, and it's a shift in expectations to have a just-in-time, real-time, Amazon impact to the entire supply chain.”

According to Kieley, the real gap is in collaboration. “It’s just not happening. At best it's Excel and email sending data back and forth, never really knowing the most accurate source of truth,” Kieley says. “Manufacturers need visibility and real-time collaboration with strategic trading partners, which ties accountability to supplier performance, enabling manufacturers to better perform through rapidly changing demand cycles.”

About the Author

Peter Fretty

Technology Editor

As a highly experienced journalist, Peter Fretty regularly covers advances in manufacturing, information technology, and software. He has written thousands of feature articles, cover stories, and white papers for an assortment of trade journals, business publications, and consumer magazines.