So that Happened: See Jane Run (a Global Procurement Network), Robot Teaches a Russian Child Lesson in Chess Etiquette

Editor’s note: Welcome to So That Happened, our editors’ takes on things going on in the manufacturing world that deserve some extra attention. This will appear regularly in the Member’s Only section of the site.

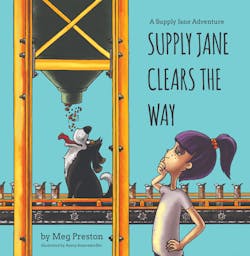

Hey Kids, It’s Supply Chain Story Time

Got a toddler with a passion for logistics? Does your kindergartner know where to get the best Legos at the lowest price, with a fast turnaround time? Well, then, do we have a picture-book series for your family. “The Supply Jane and Fifo Adventures” by former manufacturing/supply chain analyst turned author Megan Preston Meyer, introduces kids to the world of bottleneck-fixing and inventory-managing through the antics of precocious, magenta-haired Jane and her friendly St. Bernard sidekick, Fifo.

There are three books in the series: “Supply Jane Clears the Way,” for instance, “teaches kids about the theory of constraints.” And “Fifo Saves the Day” will introduce Junior to “the concept of First In, First Out” and give a “better understanding of perishable goods handling and inventory management procedures.”

“Those books are fine for the STEM classroom,” you may say, “but what can I put under the tree for Christmas morning?” Well, glad you asked, because the series includes a holiday-themed book: “Twas the Month Before Christmas: A Supply Chain Carol.” Hopefully, it won’t be held up in the Port of Los Angeles over Thanksgiving weekend.

Abandoned Steel Factory in Pittsburgh Finds New Life Making Solar Tracker Equipment

In the manufacturing world, it’s especially nice to see a former facility find new life. An historic Bethlehem steel manufacturing factory in Leetsdale, near Pittsburgh, will now be producing utility-scale solar trackers. Nextracker, LLC has joined with BCI Steel to make this happen.

Steel and Pittsburgh are just inseparable. “BCI is proud to advance Pittsburgh’s legacy as the heart of America’s steel industry,” said Matt Carroll, CEO of BCI Steel, in a statement. “This partnership with Nextracker showcases our steel fabrication and quality control technology and unlocks additional domestic solar capacity with our low-cost manufacturing.”

The announcement made sure to let it be known that the steel processing plant will incorporate both BCI Steel’s new and reshored equipment that was shipped to the U.S. from factories in Malaysia and Brazil.

Solar tracker products produced at the factory will serve rapidly growing solar markets in Pennsylvania, Indiana, New York, and Ohio. “This investment will increase the resilience of the U.S. solar supply chain and bring manufacturing jobs, equipment, and capacity back to America,” said Dan Shugar, CEO and Founder of Nextracker.

It is Nextracker’s goal to increase domestic production and in the past year, the company has opened other facilities including a green steel tracker production line in Texas with JM Steel, as well as another dedicated steel production line in Arizona with Atkore. The company is building out 10 GW of “Made in America” manufacturing capacity — enough to power 7.5 million homes.

Chess-playing Robot Breaks Child’s Finger

In a high-profile ISO/TS 15066:2016 safety violation, a chess-playing robot pinned a 7-year-old's finger during a Russian chess tournament, eventually breaking it. Russia’s Taas news agency said the incident took place during the Moscow Chess Open earlier this month.

According to Taas, the child played his piece too quickly, confusing the robot which was playing four matches simultaneously. The robotic arm pinned the child’s hand, eventually exerting enough force to break a finger. The child was treated and played the rest of the tournament with a cast on his hand.

Sergey Lazarev, President of the Moscow Chess Federation, said, “The robot broke the child's finger. This, of course, is bad.”

Taas did not offer details on the robot (other than to note that it was an exhibition unit that did not belong to the Chess Federation), so it’s unclear what control and safety systems it used and why it continued to exert force once it encountered resistance from something softer than a wooden chess piece. The ISO 15066:20016 standard recommends an IEC 60204-1 Level 2 monitored stop on collaborative robots, meaning an override that leaves power available to the robot’s actuator (unlike a Level 0 stop that cuts power). However, such a system assumes the robot would be monitored, and Lazarev told Taas that “operators overlooked” the child playing against the robot.

Make Pizza at Home, Save Money?

Modern home kitchens require a basic suite of major appliances—stove, refrigerator, oven, dishwasher. But, what about the people who need to cook gourmet pizza four or five times per week?

GE Appliances, a Haier company, launched production this month of a product just for them. The Monogram Smart Flush Hearth Oven is an all-electric pizza oven, capable of 1,300 degrees needed to really get that crispy crust that aficionados crave. All that for only $9,000.

Clearly, this isn’t for every home, so GE Appliances is experimenting with different manufacturing techniques to make low-volume, high-mix manufacturing more efficient. Enter the recently opened CoCREATE Stamford microfactory in Connecticut. Unlike the company’s massive Louisville, Kentucky, facility that cranks out washing machines and dishwashers by the thousands, Stamford’s 25 employees hand craft most of their low-volume by very expensive products.

GE Appliances President & CEO Kevin Nolan said, “Manufacturing is our foundation, but our factory is only the start of what’s to come here. We’re energized about the possibilities ahead when CoCREATE Stamford fully opens to the community and look forward to bringing people together to innovate, educate and inspire.”

In addition to manufacturing space, the Stamford plant has room for hands-on job-training and educational facilities.

About the Author

IW Staff

Find contact information for the IndustryWeek staff: Contact IndustryWeek