2013 IW Best Plants Winner: Harley-Davidson -- Driving a Future of Excellence

A concrete expanse stretches behind a chain-link fence, weeds cropping up through the growing cracks in the ground that once supported a robust manufacturing operation.

The vacant lots serve as daily reminders of the transformation the Harley-Davidson plant in York, Pa. has undergone.

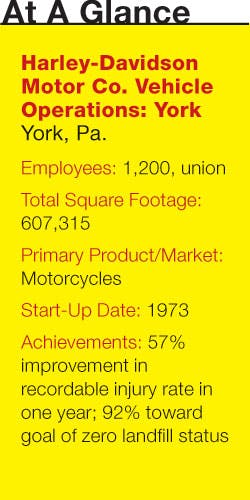

The plant, which once cast a mammoth 41-building shadow, now occupies two buildings with just one used for manufacturing.

Four years ago, 89% of the International Association of Machinists and Aerospace Workers employed at the York site accepted a concession-laden contract that would eliminate half of their jobs. Harley-Davidson Inc. (IW 500/183), struck by the recession, wanted to cut costs and was planning to do so either at the Pennsylvania site or by building a new facility in Kentucky.

Without the contract, without the jobs, York was fated to close.

"They voted to keep the jobs in York," says Jim Waltermyer, union president.

Today, what is now referred to as New Factory York is a lean operation.

The plant management used the restructuring in York as an opportunity to completely rethink its leadership structure and retool its operations -- to truly create a new factory.

It replac"Work was getting done, but it was not a world-class manufacturing environment," says Ed Magee, New Factory York general manager. "We wanted to create a sustainable lean culture."

Within the four walls of its lone manufacturing building in York, roughly 1,000 production workers now fabricate, paint and assemble motorcycles in three process areas with a system simplified by automated guided carts.

Conveyor belts transporting parts through the painting process that once stretched nine miles are now three miles in length.

Robots now rhythmically weld parts together -- faster, more precisely. They churn out 20% more fenders per shift than in years past, with two fewer employees.

In the flatter organization, workers now have one of five job classifications, a notable change from the 65 classifications used in the old framework.

New Factory York also now relies on flexible workers to supplement its leaner workforce. During what it calls its surge period, the company ups its production by 50% and brings in a bevy of flexible workers to work side-by-side with full-time hourly employees.

"We're making more motorcycles in one building than we did in all of those old ones," Magee says.

And "we never stopped producing motorcycles while switching over," he reveals.

Read more about 2013 IW Best Plants winners.

See the IW Best Plants winners at the 2014 IW Best Plants Conference.

About the Author

Ginger Christ

Ginger Christ, Associate Editor

Ginger Christ is a former associate editor for EHS Today, a Penton publication.

She has covered business news for the past seven years, working at daily and weekly newspapers and magazines in Ohio, including the Dayton Business Journal and Crain's Cleveland Business.

Most recently, she covered transportation and leadership for IndustryWeek, a sister publication to EHS Today.

She holds a bachelor of arts in English and in Film Studies from the University of Pittsburgh.