Quantifying the Financial Benefits of Quality: Bringing Suppliers into the Fold

In part two of this series, we discussed the role governance and reporting practices had on the level of financial benefits organizations derived from their quality efforts. What we found was that similar to findings in earlier studies, quality governance models and transparency (reporting and standardized measures) improve the efficacy of organizations’ quality efforts.

Given that transparency and cross-functional integration help improve the financial benefits of quality, we also wanted to understand what happens when organizations extend those factors (transparency and collaboration) to partners outside of the organization through training. Hence in this article, we will discuss the relationship between quality training for suppliers and the financial benefits of quality.

Training Suppliers and Financial Value

Suppliers play a major role in any organization’s quality—they provide the materials necessary to create products. To understand the relationship between suppliers and quality efforts, respondents were asked to indicate which suppliers they will train on quality management practices within the organization.

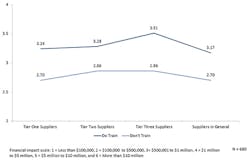

Surprisingly, the vast majority of organizations do not provide any training for their suppliers on their quality management system. Of those that do provide training, it is often limited to tier one suppliers. This means most organizations are missing out on opportunities to ensure transparency between the organizations, create a common language and set expectations with suppliers on quality needs. To test where organizations need to invest in training, we ran analysis against which tier of suppliers were provided training and the organizations’ financial benefits of quality (Figure 1).

There is a case to be made that training for any suppliers will generally improve the organization’s financial benefits—illustrated by the increase on average from the financial benefits range of $100,000 to $500,000 for those who do not provide training to a range of $500.001 to $1 million in benefits for those that do. However the largest improvement in financial benefits comes from training the often overlooked tier three suppliers. This does not mean that organizations should ignore their tier one and two suppliers, but instead should extend their training to their tier three suppliers.

However, this then begged the question: What types of training should organizations offer their suppliers?

What Training Matters?

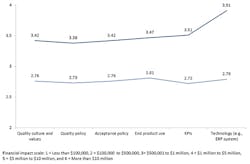

In addition to the general ideas of transparency and common language organizations need to help their suppliers understand the impact that defects or other setbacks like delays will have on their end customer. This helps the organizations eliminate waste and ultimately improve the efficiency and quality of their products, resulting in higher customer satisfaction and potential price premiums. This theory leads to the hypothesis that organizations that train their suppliers on their quality culture and end use of product would see the largest financial benefits. To test this hypothesis we ran the types of training offered suppliers against the financial benefits of quality (Figure 2).

What we found was that all the types of training discussed in the survey correlated to improved financial benefits. However the general hypothesis that organizations that provide training focused on the organization’s quality value, policies, and end product use suppliers would reap higher financial benefits was not supported. Instead organizations that provided training on their quality KPIs and technology systems (e.g., ERP systems) were more likely to reap higher financial benefits. Though additional value can be created through a shared understanding of customers and quality culture, organizations should start with ensuring clarity around foundational items such as measures and reporting technology.

Conclusion

Best-in-class quality organizations use training with their suppliers to drive quality and are twice as likely to train suppliers. Supplier training ensures that all critical parties in the value chain understand the organization’s standard of quality—around quality measures and efficacy and what it wants to achieve with its product offerings. In the final article, of this series we will look more closely at the relationship between incentives and training for staff and the financial benefits of quality.

Holly Lyke-Ho-Gland is process and performance principal research lead with APQC, a member-based nonprofit and one of the leading proponents of benchmarking and best practice business research.

About the Author

Holly Lyke-Ho-Gland

Holly Lyke-Ho-Gland is a principal research lead who conducts and publishes APQC research on process management and improvement, quality, project management, measurement, and benchmarking for APQC’s Process and Performance Management research team. Her research supports APQC members and clients across disciplines and centers on helping professionals and project managers solve business problems with strategy, process and measurement.