To Fix Quality, You Must First Fix Culture

Many companies express the need for continuous improvement. But have you ever stopped to ask why so many of these improvement efforts fizzle? More specifically, why are continuous improvement efforts not continuous?

In this article, we take a look at the standard approaches to quality improvement and discuss why it may be time for a more innovative and contemporary approach.

Common Quality Models

Some well-known quality models have demonstrated clear value and been used by many quality professionals. But did you know that these models are over 30 years old?

- Statistical Process Control: 1924

- Total Quality Management: 1985

- Six Sigma: 1986

- ISO 9000: 1987

- Lean Management: 1988

Think about some of the significant changes in our world over the last 30 years and how they have transformed the way we work. Consider some of the major changes we have been through, such as:

- Technology evolving at an exponential rate.

- Social media creating absolute transparency.

- Global logistics transforming supply chains.

- Social movements increasing equal rights awareness.

- Pandemics changing workplace dynamics and structure.

While all the above quality models have demonstrated success in the past, why are they not as effective as they once were? What is missing, and why have improvement efforts not been sustainable?

The Need for a Different Approach

I have had the opportunity to work in multiple companies over my 30+ year quality career, both Fortune 500 corporations and small startups. When I began to reflect and explore why some improvement efforts worked—and, more often, why some did not,—I realized that the companies’ culture played a big role in the success or failure of their improvement initiatives.

When people are engaged and excited about their company and their role in its success, quality efforts flourish. But when people are not engaged—or worse, actively disengaged—these quality efforts fade quickly and ultimately fail. In situations where the culture is toxic, nobody is thinking about doing their best. They are either “quiet quitters” (doing the bare minimum) or actively disengaged and searching for a new opportunity. They most certainly are not committed to quality improvement.

You must fix the culture before you can fix the products and processes.

Because so much has changed in our world over the last 30 years, I believe we need a new quality model. A model that starts with people, not a process or methodology.

A New Model

I would like to introduce the Sustainable Quality model.

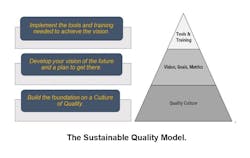

The Sustainable Quality Model is comprised of three distinct tiers. The first tier (bottom of pyramid) is a Quality Culture. The second tier is Quality Strategy. The third and top tier is Quality Tools & Training. There is a set order to this model.

Think of these tiers as building blocks. You cannot start framing a house unless it is built on a solid foundation. Culture is that foundation--and that’s what we will focus on here.

Too often as quality professionals, we lead with methodologies and techniques. This is wrong thinking. Build the foundation first. Then create a vision and plan for the future. This sets direction and aligns people. The tools and techniques come last. At this point, your organization is in the position to select the right methodology for your specific situation.

This model only works when there is a commitment from top leadership to change the way they think and lead with a new mindset.

Building a Quality Culture

Stop for a moment and think of a time in your personal or work life when you were at your very best. How did you feel about the environment you were working in? What type of encouragement and support did you have? How did you feel about the actual work you were doing? What were the driving factors that made this important to you?

I believe a long-term, sustained commitment to quality only comes from employees who are engaged and inspired to do their best. They have “bought-in” both to what they are doing and who they work for. They have a sense of purpose and understand how their role contributes to that purpose.

This type of performance mindset becomes possible when personal, team and company goals all align. It flows from a positive work environment where employees feel valued and appreciated.

This type of culture does not lack accountability. In fact, I believe people want to be accountable. They just need a clear understanding of what is expected of them and why. A Quality Culture indicates a sense of belonging and pride in the company and becomes a reflection of their focus and effort.

Demotivating Behaviors

The majority of America’s managers have received no formal management training, according to a study by West Monroe Partners. To keep pace, 42% of new managers admit they developed their management style by observing and mimicking a previous manager, rather than through any type of formalized training. In addition to the lack of training, many managers report they are too busy with administrative and technical tasks to adequately oversee their team.

Leadership certainly has an effect on a business’s culture. Poor leaders trigger demotivators for employees. Consider the following and you can begin to see how these demotivators diminish the work environment:

1. Being untrustworthy. Most employees quit their boss, not the company. If the employee cannot trust their direct boss, at the very least they will be demotivated. More likely they will eventually leave.

2. Bullying. A bad culture can suck the productivity out of people and kills any creativity. Toxicity paralyzes a workforce and is the top reason for high turnover. Any type of harassment or bullying causes disengagement. These types of issues will continue to escalate until workers quit or the bully gets fired.

3. Overworking your people. It is not unreasonable to occasionally expect some long hours from your employees. But if “occasionally” turns into “ongoing or normal,” that is a problem. Demanding more and more from your employees leads to burnout, more mistakes and higher absenteeism.

4. Having unclear expectations and communicating poorly. It is hard to hit the target when you don’t know what the target is. This can be so frustrating for an employee. You should never have to guess if you are working on the right thing or doing things right.

5. Micromanaging. Overmanaging or babysitting employees who do not need it kills creativity and confidence. It either drives them to stop thinking or drives them to leave.

6. Not addressing poor performance. It is never comfortable to confront an employee with a performance issue. However, that is part of the manager’s responsibility, and it impacts others when they see that poor performance is not addressed. It is no help to the poor performers either, if they do not realize there is a problem.

7. Lacking an onboarding plan. Nothing is worse than bringing a new person on board and having nothing ready for them, such as a workspace, initial tasks, training and so on. All the enthusiasm they came into the company with will begin to fade away quickly.

What is important to know about culture is that it happens. As a leader, you can intentionally create the type of culture you want. But left unattended, you will still have a culture. It just may not be the type of culture you intended.

Joseph Diele is owner and principal consultant of Diele Consulting LLC and the author of Sustainable Quality.