Planned, Reactive, Predictive: What’s the Right Maintenance Mix?

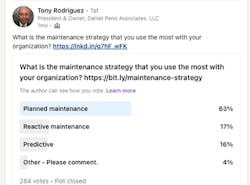

Daniel Penn Associates recently asked members of LinkedIn’s Association of Asset Management Professionals Group “What is the maintenance strategy that you use the most with your organization?”

The feedback we received was consistent with our team’s experiences. Sixty-three percent of the 284 survey participants said they most frequently use planned maintenance, 17% said they most frequently use reactive maintenance, and 16% said they most frequently use predictive maintenance.

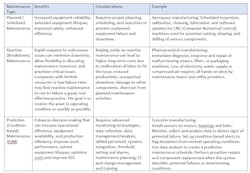

Each type of maintenance plays a role in helping manufacturers manage, maintain, and restore the health of their facilities’ valuable physical assets. Planned maintenance ensures regular upkeep, while reactive maintenance addresses unexpected failures promptly. Predictive maintenance (PdM) leverages data and analytics to predict and prevent failures.

Let’s take a closer look at the uses, considerations and benefits of each type:

A combination of these maintenance strategies can help manufacturing organizations minimize downtime, increase reliability, optimize performance and gain a competitive edge.

The Downside of Reactive Maintenance

According to research by the National Institute of Standards and Technology (NIST):

- On average, 45.7 % of machinery maintenance is reactive maintenance.

- The top 25% of those establishments relying on reactive maintenance was associated with 3.3 times more downtime than those in the bottom 25%.

- Reactive-maintenance organizations were also associated with 16 times more defects, 2.8 more lost sales due to defects from maintenance, 2.4 times more lost sales due to delays from maintenance and 4.9 times more inventory increases due to maintenance issues.

As Michael Beauregard points out in his upcoming Productivity Press book Process Downtime Reduction, the old Fram oil filter commercial was correct – “You can pay me now or you can pay me later,” but later (i.e., reactive) always costs more.

Looking to The Future of Predictive/Condition-Based Maintenance (PdM)

Given that unplanned downtime costs industrial manufacturers an estimated $50 billion annually and that equipment failure is the cause of 42% of this unplanned downtime, companies are beginning to use PdM methods that incorporate technology, set condition-based alerts and provide training to help manufacturers discover and fix issues before they become full-blown crises. New artificial intelligence tools (AI) can help maintenance professionals quickly aggregate and analyze maintenance data.

NIST reports that the top 50% in predictive maintenance “experienced 15% less downtime, an 87% lower defect rate and 66% less inventory increases due to unplanned maintenance.”

Bringing It Together

Reliability Centered Maintenance (RCM) is a systematic approach to maintenance planning and decision-making that optimizes the reliability, performance and safety of physical assets. It involves analyzing the functions, potential failures, and consequences of failures of equipment to determine the most effective maintenance strategies. RCM includes:

- A focus on emphasizing, identifying and prioritizing critical functions of equipment that are essential for achieving desired outcomes. These are determined based on the equipment's purpose and the organization's objectives.

- Failure modes and effects analysis (FMEA) to help understand the risks associated with equipment failure and enable proactive maintenance planning.

- Maintenance strategy selection for different types of failures, considering such factors as the criticality of the function, cost-effectiveness, safety implications and potential impact on production.

- A proactive maintenance approach that focuses on preventing failures rather than simply responding to them and implementing preventive or predictive maintenance activities to minimize risk.

- Evaluation and optimization of maintenance tasks on equipment to determine the optimal frequency of inspections, tests, lubrication and other activities based on reliability, performance and cost considerations.

- Continuous improvement, by collecting data and feedback on the effectiveness of maintenance strategies. This information is used to refine maintenance plans, optimize asset performance, and enhance overall reliability.

As one of the plant asset management leaders in our LinkedIn survey noted, “The idea in any reliability-centered maintenance program is to monitor all possible failure modes with key trending health parameters. Depending on the alarms we set up for normal and warning signs, we can decide on which strategy is best suited to eliminate the abnormality.”

An Integrated Path Forward

Bringing these elements together helps manufacturers in their maintenance and asset management programs:

How is your organization incorporating technology, tools and training to help it migrate from reactive to preventive and proactive maintenance?

Tony Rodriguez is president of Daniel Penn Associates. The firm has over 45 years of consulting experience helping companies improve asset management, operational excellence and lean management.

***To comment on this article, please scroll down past story recommendations to "Voice Your Opinion."