The Dangers of Disguising Cost Cutting as Improvement

"You know something? I think it would have been better on everyone if we had not tried to improve anything. It is tough to experience the way things could be and then have the rug pulled out from under you. It just reinforces the misery,” said Julie. -- from “How Many Times Has Your Company Started (and Stopped) Implementing Lean?”

What is the real reason your company is driving an improvement initiative (lean, Six Sigma, etc.)? Is the improvement effort part of a long-term (multiple-year) strategy that is focused on growing the business by dazzling your customers and exceeding their expectations? Or, is the focus to cut costs? Or, did the effort start as a long-term focus on improving the customer experience and, at some point, switched to short-term cost cutting? This can easily happen if the company executives don’t grasp the real power of doing lean and Six Sigma the right way and they grow impatient to see results.

Employees who work in a company that falls into this last category probably share Julie’s frustration. Julie is a character in my last article, but I have had this experience myself. Earlier in my career, we launched a new improvement effort as part of a long-term strategy to grow the business. The first year was exciting and well received by most of the employees. They were given opportunities to go through training and to participate on improvement teams. Tangible, employee-led changes could be seen throughout the plant, and the customer experience metrics showed steady improvement. Morale was the highest anyone could remember.

Then, the bottom fell out. The company executives began to realize that the improvements were having a real impact. They then decided to shift the focus of the improvement teams to cost cutting in order to meet their short-term financial objectives. Jobs were eliminated. When this happened, employees became bitter, quit participating on the teams and morale suffered. Most of the improvements from the previous year were not sustained, and things quickly returned to the way they were before (or worse).

Several employees shared with me the same sentiment as Julie in the story. They got a chance to experience the way things could be, and then the rug was pulled out from under them. This huge swing in culture resulted in a significant let down, and many employees became extremely bitter.

The book “The Goal” shared that the real goal of any business is to make a profit. So, cost considerations are important. However, why does the focus on pure cost cutting result in improvement failure? It might help to first understand the different types of cost reductions.

- “Hard” Cost Savings – Hard costs are easy to see and calculate on a spread sheet. The two most prominent hard cost savings are material and employee costs (direct, indirect and overhead). Material costs include price and usage. Most employee improvement teams will have little say in price negotiations with suppliers, and reducing the usage of materials usually requires some sort of engineering design change. For employee costs, when a company eliminates a job and an employee leaves the payroll, it is easy to calculate how much savings there will be in salary and benefits. So, most “hard” cost savings end up focusing on job elimination.

- “Soft” Cost Savings – Soft costs are all of those incremental changes that improve the customer experience and will eventually help the company sell more product. Eliminating waste, breaking bottlenecks, reducing cycle times and improving the reliability of the product are some examples of soft costs. The reason the financial community calls these “soft” costs is that it is difficult to put an actual dollar amount to these savings. For example, how much money does the company save if a machine set-up time is reduced by 50%? This would result in greater flexibility to meet changing customer needs and smaller batch sizes (resulting in a small amount of savings in the reduction of work-in-process inventory). However, it is difficult calculating the amount of money that actually hits the bottom line. For this reason, some (most?) executives say that soft savings are “smoke and mirror” savings… meaning that they are probably not real or are exaggerated (this is especially true for executives who have not been properly trained in the power of lean and Six Sigma).

- Cost Avoidances – Your improvement team just identified and permanently fixed a problem that if it had occurred, would have shut the production line down for days, weeks or even months. There will be a huge celebration! Maybe not. The company leaders will probably look at this type of project and want to know when the problem that was avoided would have occurred and how much damage there would have been. Since the answers to these questions are impossible to know with certainty, the savings will never be calculated and little to no credit will be given.

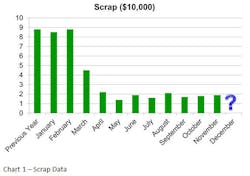

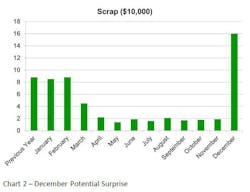

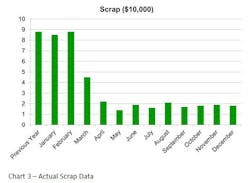

- Verifiable Cost Savings – This is the most frustrating savings category for improvement teams. A good example is a major scrap-reduction project. At the beginning of the company’s fiscal year, the accountants try to anticipate how much scrap will be generated for the upcoming year. They base this on historical scrap levels and projected volume data. A financial “reserve” of money is put into the budget to cover these anticipated costs. Let’s say that an improvement team is 100% certain that they were able to get to the root cause of a major quality issue and implement a change that will cut the scrap significantly. Data that are tracked monthly clearly show, through November, the impact of this project as the scrap numbers drop throughout the year (See chart 1).

So, of all of the cost savings categories, the only one that is easy to calculate and has an immediate impact is job elimination. Since employees do not want to be a part of eliminating jobs (office jobs included), this will lead to a complete and total collapse of the improvement effort.

What can be done instead?

Consider These Action Steps

First, make sure everyone in the company gets proper training in the improvement tools and philosophies. This includes the CEO, CFO, upper management, the engineers, supervisors and workers in every function. If the CEO and upper management refuse to attend the training, then you are probably already on a path for failure.

The training does need to be memorable and impactful. I have been training workers at all levels and functions for over 25 years and concluded over that time that training needs to be interactive and hands-on in order to create a step function change in understanding and embracement. If the training in your company has too much lecture with hundreds of PowerPoint slides, then don’t be surprised when most of the class has tuned out after only a few minutes and little knowledge is gained.

Second, spend time with the financial community and hold discussions on costs and savings before the improvement projects get started. An impactful exercise is to take a specific problem or situation (such as a machine tool shattering due to using worn inserts) and ask the financial folks to try and identify all of the different cost categories associated with that issue. Then, assign each of those cost categories into one of the four types listed above. Next, discuss how those costs might be calculated and tracked. Finally, work with the financial folks to develop a way to report these savings in a way that is believable and will be embraced by the company leaders.

Next, make it mandatory that a person from the financial community participate or be a resource for each of the improvement teams. There is a much higher chance that the CFO of the company will embrace the cost savings (even the “soft” savings and cost avoidance amounts), if those figures come from or are verified from someone in their department.

Finally, as was mentioned earlier, lean, Six Sigma and any other improvement initiative needs to be part of a longer term strategic plan focused on wowing the customer. In fact, the real grand slam homerun in all of this is to focus on the following: 1) Determine your customers’ expectations and develop a value proposition that exceeds those expectations; 2) Implement lean and Six Sigma to eliminate waste, chaos and uncertainty in the processes so employees can work smarter and process become more predictable; 3) Increase capacity by breaking bottlenecks that are now more apparent; 4) Sell more product or services to customers who are extremely satisfied with the company’s performance; 5) With the same number of employees, produce more product or provide more services (labor cost per unit drops, leading to true productivity); 6) Profits go up, employees are happier with more job security and your customers are thrilled. Keep in mind that it may take two or more years to reap these benefits.

It is critically important to the success of any improvement initiative that everyone in the organization understands the real reason why these changes are being made. Is it to cut costs? If so, then expect to experience a complete and utter collapse of your improvement efforts. Is the reason to grow the company by improving the customer experience and providing a good value, on time, when the customer wants the product or service? If this is the case, there is a chance of success beyond anything you might imagine.

John Dyer is president of the JD&A – Process Innovation Co. and has 28 years of experience in the field of improving processes. He started his career with General Electric and then worked for Ingersoll-Rand before starting his own consulting company. Dyer can be reached at (704)658-0049 and [email protected]. See his LinkedIn Profile. He is on Twitter: @JohnDyerPI.

About the Author

John Dyer

President, JD&A – Process Innovation Co.

John Dyer is president of JD&A – Process Innovation Co. and has 32 years of experience in the field of improving processes. He started his career with General Electric and then worked for Ingersoll-Rand before starting his own consulting company.

John is the author of The Façade of Excellence: Defining a New Normal of Leadership, published by Productivity Press. He is a frequent speaker on topics of leadership, continuous improvement, teamwork and culture change, both within and outside the manufacturing industry.

John is a contributing editor for IndustryWeek, and frequently helps judge the annual IndustryWeek Best Plants Awards competition. He also has presented sessions at the annual IW conference.

John has an electrical engineering degree from Tennessee Tech University, as well as an international master's of business from Purdue University and the University of Rouen in France.

He can be reached by telephone at (704) 658-0049 and by email at [email protected]. View his LinkedIn profile here.