What is Enterprise Lean and How do we Get There?

I often hear executives say that localized lean is not enough and they are going to implement enterprise lean. What I believe they are saying is that they have started a lean program, or seen a lean program in another company, that focuses on selected processes in localized areas and it does not have a big enough or fast enough impact at the enterprise level. What they want is speedy, large, measurable impacts on business metrics that matter. To do this they want to streamline enterprise-wide processes from raw material to finished goods.

This in fact makes sense as a vision but the question is whether it is feasible in the way they are thinking about it. I recall advising a vice president of continuous improvement in a large company that had arranged with Toyota to receive help from a leading Toyota Production System sensei. The CEO had requested a value stream map from raw material to the customer and proudly shared it with the TPS sensei. He expected this expert on TPS to be impressed and perhaps have a few technical suggestions, but instead was shocked to hear, “Problems, problems, so many problems. Where are you going to start?” The sensei then walked out of the room.

The question he asked me was: What was this Toyota guy thinking and why wasn’t he impressed? I explained that the sensei saw a large piece of paper enumerating complex problems throughout the company and it was unlikely anyone in the company had the capability to really address any of these problems in a deep way, at the root cause, in a way that is sustainable. Thus, it becomes a paper exercise leading to a lot of orders to fix things and it is bound to fail.

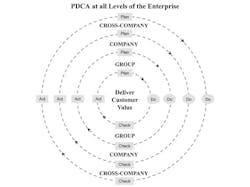

I am suggesting there is a large gap between the theory and the practice of enterprise lean. In The Toyota Way I presented a model of Plan-Do-Check-Act at all levels of the enterprise from the total value stream down to individual level work groups (see figure below). The point was that the same process of improvement needs to happen at all levels.

What PDCA really represents is a scientific mindset which follows a clear pattern. This cycle can be practiced at all levels of an organization (i.e., it's fractal and nested), although the higher you go the more strategic in content and slower-turning the cycle gets. In the figure we show this pattern. The Plan is a desired direction and testable prediction of what we think we can accomplish, the Do is an experiment to try out an idea to move us in this direction, the Check (or Study) evaluates what happened, and the Action identifies what we learned by comparing our plan to what actually happened. I have discussed in more detail the methodology of carrying this out through defined routines (kata) in a previous blog.

Since PDCA is the process needed to carry out sustainable improvement at all levels, it requires skilled practitioners at all levels—from the C-suite to the working level. In practice we rarely see people implementing lean who are carrying it out scientifically. We see various tools and programs implemented with inadequate planning, superficial evaluation and little residual organizational learning. We see complex programs force fit to the organization without individual pieces tested, refined and made to work effectively. Deming referred to this attempt as “instant pudding” where we want to shortcircuit the hard work of developing the people, processes and tools to operate in a new way to better deliver value to the customer.

What the lean sensei from Toyota saw was an organization likely to create a lot of instant pudding, but make little deep sustainable change. The only way he knew how to teach them the difference was to show them, but he could not show them at the enterprise level. It was too complex with too many people, departments and moving parts. So like almost every other Toyota sensei he chose to show them in a smaller demonstration area in one of their factories.

The purpose was not to change the whole company 200 square feet at a time, but rather to demonstrate a pattern for improvement that can be replicated any place at any level in the company. He wanted them to learn from the first experiment. Once they understood what was required for sustainable change, they could begin to plan out where to go next and get a sense of the speed of change possible as well as the degree of investment in developing people that was necessary.

If they truly learned from this one small experiment it would rock their world—changing their mindset about the nature of lean transformation. Then they would look at the enterprise-wide value stream map on the wall and ponder: What were we thinking?

_____________________________________

Join the Liker Leadership Online Community and access our webinars, courses, and consulting services.

Liker Leadership Institute (LLI) offers an innovative way to learn the secrets of lean leadership through an online education model that is itself lean, and extends that lean education far beyond the course materials. Learn more about LLI's green belt and yellow belt courses in "The Toyota Way to Lean Leadership" and "Principles of Lean Thinking" at the IndustryWeek Store.

About the Author

Jeffrey Liker Blog

CEO

Dr. Jeffrey K. Liker is Professor of Industrial and Operations Engineering at the University of Michigan and a professional speaker and advisor through his company Liker Lean Advisors (LLI), an organization established with a network of associates to teach and consult in the Toyota Way. He is also CEO of Lean Leadership Institute, the home for online courses beginning with The Toyota Way to Lean Leadership.

Dr. Liker is author of the international best-seller, The Toyota Way: 14 Management Principles from the World's Greatest Manufacturer (McGraw Hill, 2004), which speaks to the underlying philosophy and principles that drive Toyota's quality and efficiency-obsessed culture. The companion (with David Meier) Toyota Way Fieldbook (McGraw Hill, 2005) details how companies can learn from the Toyota Way principles. His book with Jim Morgan, The Toyota Product Development System (Productivity Press, 2006), is the first that details the product development side of Toyota. His articles and books have won nine Shingo Prizes for Research Excellence and The Toyota Way also won the 2005 Institute of Industrial Engineers Book of the Year Award and 2007 Sloan Industry Studies Book of the Year. In 2012 he was inducted into the Association of Manufacturing Excellence Hall of Fame. He is a frequent keynote speaker and consultant.