Operations: Cost Reduction Strategies Steer Away from Outsourcing

The bloom may be off the rose when it comes to sending manufacturing offshore -- and that statement is open for debate -- but manufacturing's drive to bring down costs remains as popular as ever. What has changed is where companies are looking to dial down the dollars.

"Over the past few years major companies have outsourced the large majority of the activities that can be managed by third parties, to take advantage of low-cost locations," says Dave Sievers, a principal and the practice leader of the Hackett Group's Strategy & Operations Practice. And while such outsourcing hasn't gone away, it has reached a level of maturity and no longer remains a primary cost-reduction technique.

See Also: Operations Management Strategy & Best Practices

"New opportunities for cost reduction are emerging, including internal optimization, materials cost cuts and reduced energy prices. For 2013, companies are clearly focusing on building the skills and infrastructure they need to take advantage of these trending opportunity areas," Sievers says.

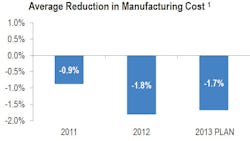

U.S. manufacturers are targeting a 1.5% reduction in the cost of goods sold in 2013, according to the Hackett Group's 2013 manufacturing cost optimization study. It will be driven in part by a planned 1.7% reduction in internal manufacturing costs.

Driving Down Costs

Sievers outlined several measures manufacturers are taking to drive efficiencies. They include:

• Plant network management. Companies not only have an eye on removing underperforming plants but also aim to boost productivity by improving capacity utilization, allocating production more efficiently and making decisions more holistically rather than with a plant-by-plant approach.

"We don't expect to see a net reduction in the number of plants but better usage," Sievers says.

- Integrated business planning. Companies are investing in information technology to support their drive for a more efficient plant network. They are taking that same mindset to their supply chain and other networks.

- Where it makes sense, manufacturers are investing in equipment and systems to improve productivity. That said, investment in upgrading or building additional capacity is down by half from 2012. Instead, manufacturers are placing a higher investment priority on training.

- Lean manufacturing and other continuous-improvement actions remain a significant means by which plants are improving operations.

In other study results, manufacturers anticipate reducing material costs by 1%, largely due to lower commodity prices. The Hackett Group suggests that reducing product complexity may help manufacturers take better advantage of better pricing. Favorable energy prices could help fuel a 2% reduction in logistics costs and a 1.7% drop in warehousing costs, aided by manufacturers' efforts to optimize those functions. The supply chain will be an investment priority as manufacturers work with their partners to develop joint capabilities.

For any company embarking on a cost-reduction strategy, Jason Piatt, president of Praestar Technology Corp., advises keeping a long-term perspective: "All too often, we see a heavy focus on quarterly outcomes by operations executives. This focus yields quick cost cuts that ultimately sacrifice the key competitive advantages for the firm over the long haul. Maintain focus on key competitive advantage, and the rest will take care of itself."

About the Author

Jill Jusko

Bio: Jill Jusko is executive editor for IndustryWeek. She has been writing about manufacturing operations leadership for more than 20 years. Her coverage spotlights companies that are in pursuit of world-class results in quality, productivity, cost and other benchmarks by implementing the latest continuous improvement and lean/Six-Sigma strategies. Jill also coordinates IndustryWeek’s Best Plants Awards Program, which annually salutes the leading manufacturing facilities in North America.

Have a story idea? Send it to [email protected].