So That Happened: Hog Wild on Electrics and Burning Down the Robot Cars

Editor’s note: Welcome to So That Happened, our editors’ takes on things going on in the manufacturing world that deserve some extra attention. This will appear regularly in the Member’s Only section of the site.

Manufacturing Love on Valentine’s Day

You've got to give a hand (or maybe a heart) to SPX Flow Inc. for its clever embrace of the Valentine's Day spirit this Feb. 14. "From factory to forever, SPX FLOW is at the heart of lasting love," notes a press release issued by the Charlotte-based manufacturer of process technologies on Wednesday morning. “From decadent chocolate hearts to enchanting perfumes, our products help capture the sentiment of this special day.”

SPX Flow shared examples of its "heartfelt engineering behind Valentine's Day," illustrating how its products contribute to Valentine’s Day traditions. Take flowers, for example: "That beautiful bouquet of roses is made possible through the careful regulation of temperature using pumps from Johnson Pump. These pumps transfer heat from storage tanks to a manifold, releasing it into the greenhouses. The controlled environment nurtures the flowers, ensuring they bloom into a stunning arrangement that symbolizes love and beauty."

Then there’s perfume, another Valentine's Day staple: "Blending the perfect scent involves the efficient agitation of fragrant flowers to extract their aromatic oils. Lightnin's advanced mixing techniques transform these oils into enchanting perfumes that captivate the senses and create lasting memories."

SPX Flow also shares its contribution to additional Valentine’s Day traditions, including chocolate, wine, jewelry and, of course, greeting cards. “Where greeting cards are made, our Power Team hydraulic cylinders, pullers and pumps maintain the equipment behind your message of love. From the intricate designs to heartfelt sentiments, manufacturing ensures the production of high-quality Valentine's Day cards that resonate with emotion.”

As I always say, everything is manufacturing, including Valentine’s Day. Nicely done, SPX Flow. Now I’m busting open a piece of chocolate.

—Jill Jusko

Orbital 3D Printing and Continued Cybersecurity Shenanigans

As much as I hate to make my So That Happened entries all about cybersecurity, here we go again. Schneider Electric, obviously a company of interest for IndustryWeek, was hit with a ransomware attack and requisite theft of corporate data on January 17 that was reported by the company on January 29.

According to BleepingComputer the attack was directed at the company’s Sustainability Business division, disrupting some of Schneider’s Resource Advisor cloud platform and reportedly resulting in the theft of terabytes of data and a ransomware demand. Clorox and DuPoint are among some of the Sustainability Business division’s customers.

I like to wait until more of the story’s out there before formally reporting a hack, in this case whether a ransomware demand was actually made and what the particulars are. Right now I’d say the most interesting aspect of the story is, once again, the period between when the breach took place and when it was reported.

Schneider did not report this as a material event, so the new SEC reporting regulations don’t apply, but this still makes me wonder how the delay between identifying and reporting a breach will play into the new rules if a breach is material and we see this recurring delay. I think we’ll find out soon enough whether those new regs have any teeth or whether the SEC will have to adjust the timeline.

(An aside: I learned recently from a cybersecurity contact that security experts advise clients to never say the word “breach,” as it may create liability. Rather, companies are supposed to report “incidents,” which covers attempts to breach that failed and/or attempts that succeeded. The word “hack” is likewise problematic and to be avoided. Something to look out for as you see cybersecurity reporting here and elsewhere and/or read corporate cybersecurity statements issued in line with the new reporting regs. Could be interesting to watch but no promises.)

Also wanted to note this week that the global manufacturing OEM AddUp partnered with Airbus Defense & Space and delivered to the Europe Space Agency a metal 3D printer designed to work in microgravity, that by now should be installed on the International Space Station with printing operations scheduled to begin late this month or in early March.

Printing components in remote locations, like on military installations far from supply lines is one of additive manufacturing’s most cited advantages for manufacturers. Deployment in space was inevitable—talk about remove from supply lines, it can take up to a year to plan and launch a supply flight to the station—and it will be interesting to see just how complex a part astronauts can print on the station.

— Dennis Scimeca

Electric Hogs Gaining Some Traction?

LiveWire, the electric motorcycle spin-off of Harley-Davidson, reported Q4 and full year results last week, and while the numbers aren’t huge, they’re pointing in the right direction. In the last few months of 2023, the company sold 514 bikes, a 645% increase from same time last year’s 69 units.

The growth can be attributed to the release of its S2 Del Mar electric motorcycle, the first built on the company’s S2 platform, which sold 482 units. The model that starts at about $15,500 is the first to feature an in-house developed battery pack (capable of about 113 miles of range), motor, telematics, and other software. For the full year, the company sold 660 motorcycles and STACYC balance bikes, falling just short of the 700 – 2,000 executives had projected.

LiveWire also had large losses: Consolidated net loss was $109.6 million for the year, within the expected range of $100 million to $125 million, but 40% more YoY. According to CFO Jonathan Root, the loss was “in line with expectations and driven by planned development costs to advance EV systems and activities around Del Mar.”

Looking ahead to 2024, executives expect sales of 1,000 to 1,500 units and an operating loss between $115 million and $125 million.

—Jennifer Ramsay

Could it Drive itself to a Fire Station?

For all of the hype and investment in self-driving car systems, those systems haven’t become a windfall for automakers or tech providers. Telsa was the target of critical Super Bowl ads, calling its Full Self Driving system anything but something that can fully self-drive a car.

Multiple photos of tech-bro Tesla drivers wearing Apple Vision Pro headsets while “driving” haven’t helped assure regulators that drivers are fully engaged and ready to take over vehicle operations when things go bad.

General Motors’ Cruise subsidiary fired executives and suspended vehicle testing in California after one of its cars gruesomely killed a pedestrian.

And, it seems, Californians aren’t too happy about being the technology’s guinea pigs. California in recent years established liberal rules that allow companies to test vehicles on public streets, and the reception with human drivers has been less than stellar. In addition to the Cruise fatality, there are hundreds of complaints about self-driving cars doing just-plain stupid things like driving slowly in the middle of busy streets, taking odd routes to destinations and being moving obstacles on public roads.

According to local news reports, people celebrating in the San Francisco streets initially jumped on the empty vehicle’s hood, drawing more people to do the same. Things got really out of hand when someone threw fireworks into the vehicle, eventually starting a fire that destroyed the self-driving car.

Waymo officials told Reuters that the incident was a one-off event. However, protests of self-driving cars in California and other areas have become more frequent as use of the vehicles rise.

—Robert Schoenberger

Too Many Car Plants?

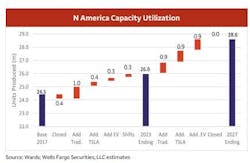

A burning question (mostly un)related to robo taxis: Will automakers have a huge plant overcapacity problem by the end of the decade? At the Federal Reserve Automotive Symposium in January, Wells Fargo’s Colin Langan estimated that between 2017 and 2027, automakers will have added 4.1 million units of additional plant capacity in North America. (The chart shows the anticipated available capacity in North America by 2027.)

Meanwhile, even as these new plants come online in places like Tennessee and Georgia (and a shuttered plant, Stellantis’ Belvidere, Illinois, facility, reopens) current plant capacity usage sits at about 70%—about 10% lower than what’s considered healthy in the industry.

“You’re going to have plants that are underutilized and that means there's going to be pressure to discount and drive share at those plants, which has historically been the major problem the industry is in,” Langford said.

Time to start thinking about how to repurpose all the excess space. Climate-controlled indoor farms to keep growing food as the temperature rises? Mega-yacht storage for oligarchs?

Or a more altruistic possbility: mega animal shelters to care for all the Fuzzbots and Barker T. Barkingtons surrendered since Return to Work began.

—Laura Putre

Operations Leadership Summit Updated Feb. 14

In June, IndustryWeek will be holding its first live, in-person event since 2022 in Indianapolis. The IW Operations Leadership Summit will gather plant managers, vice presidents of operations, department leaders and other professionals tasked with getting product out of factories.

Two weeks ago, we shared a few speaker highlights, and now, we have a few more to share:

- Regular IndustryWeek contributors Carl Livesay and Dave Rizzardo will discuss how manufacturers can extend and maintain lean manufacturing gains after implementing new programs.

- Jason Ryska, director of global manufacturing technology development at Ford Motor Co., and Fabian Ochoa, director of digital factory solutions at Emerson Electric, will share how those two companies are incorporating AI into shop-floor operations.

- Toyota Material Handling North America President and CEO Brett Wood will offer a keynote address on how the Indiana forklift plant approaches operational excellence.

And, in addition to those speakers, we’ll be offering guided plant tours that will focus on how major manufacturers apply best practices at Allison Transmission, Endress + Hauser and Subaru.

Stay tuned. We’ll have more information to share in the coming days and weeks, and we look forward to presenting a live event that will be valuable to operations leadership, the people tasked with getting product out of the plant as efficiently as possible.

—IndustryWeek Staff

About the Author

Robert Schoenberger

Editor-in-Chief

LinkedIn: linkedin.com/in/robert-schoenberger-4326b810

Bio: Robert Schoenberger has been writing about manufacturing technology in one form or another since the late 1990s. He began his career in newspapers in South Texas and has worked for The Clarion-Ledger in Jackson, Mississippi; The Courier-Journal in Louisville, Kentucky; and The Plain Dealer in Cleveland where he spent more than six years as the automotive reporter. In 2014, he launched Today's Motor Vehicles (now EV Manufacturing & Design), a magazine focusing on design and manufacturing topics within the automotive and commercial truck worlds. He joined IndustryWeek in late 2021.

Laura Putre

Senior Editor, IndustryWeek

As senior editor, Laura Putre works with IndustryWeek's editorial contributors and reports on leadership and the automotive industry as they relate to manufacturing. She joined IndustryWeek in 2015 as a staff writer covering workforce issues.

Prior to IndustryWeek, Laura reported on the healthcare industry and covered local news. She was the editor of the Chicago Journal and a staff writer for Cleveland Scene. Her national bylines include The Guardian, Slate, Pacific-Standard and The Root.

Laura was a National Press Foundation fellow in 2022.

Got a story idea? Reach out to Laura at [email protected]

Dennis Scimeca

Dennis Scimeca is a veteran technology journalist with particular experience in vision system technology, machine learning/artificial intelligence, and augmented/mixed/virtual reality (XR), with bylines in consumer, developer, and B2B outlets.

At IndustryWeek, he covers the competitive advantages gained by manufacturers that deploy proven technologies. If you would like to share your story with IndustryWeek, please contact Dennis at [email protected].

Jill Jusko

Bio: Jill Jusko is executive editor for IndustryWeek. She has been writing about manufacturing operations leadership for more than 20 years. Her coverage spotlights companies that are in pursuit of world-class results in quality, productivity, cost and other benchmarks by implementing the latest continuous improvement and lean/Six-Sigma strategies. Jill also coordinates IndustryWeek’s Best Plants Awards Program, which annually salutes the leading manufacturing facilities in North America.

Have a story idea? Send it to [email protected].