Parker Hannifin had a problem.

One of its customers -- an Italian cement maker -- was having some issues with a steel pipe it used to transport raw material through the factory. The problem was, the material is so abrasive that it wore through the pipe in less than two weeks, which required the company to essentially shut down production twice a month to repair or replace the fixtures.

So it approached Parker Hannifin (IW 500/95) with an odd request -- it needed a new pipe that was somehow as flexible as a rubber hose and yet many times stronger than steel.

The normal approach to a problem like that, explained Peter Buca -- vice president for innovation and technology at Parker Hannifin -- would be to take a look at other solutions both in-house and on the market and try to cobble together a new application that might do a better job.

But this time, Parker took a different approach.

"The division decided to look into nature to find a solution," Buca says. "They asked, 'What's out there in the world already that's flexible and yet armor plated?'"

The answer was surprising. Turns out there are three natural structures that meet those requirements: worms, fish and snakes.

And that was enough to get started.

This was Parker Hannifin's first foray into an exploding new field of product design called biomimicry.

As its name implies, biomimicry works by duplicating features and functions that have evolved in nature -- be they the self-cleaning nanostructures of a lotus leaf or the flexible strength of snake scales.

"We are surrounded by a living, learning laboratory," explains Tom Tyrrell, CEO and founder of Great Lakes Biomimicry, a northeast Ohio consortium dedicated to the development of nature-based solutions and education.

"Nature is 3.8 billion years old and has already solved every problem," he says. "For most of our time on Earth, human civilization has used nature to solve our problems, too. But for the last 200 years, it's been exactly the opposite."

Taking a biomimicry approach, he says, reverses that trend. It takes the focus away from the purely man-made engineering efforts wrought through the industrial revolution and back to the battle-tested and implicitly sustainable properties already thriving in the world around us.

As Buca puts it, "Any solution that nature has out there has been out there for millions of years. Those solutions have been tested many, many times over many, many years and are still being tested today."

When you tap into that resource, he argues, you tend to come up with a far better, and far heartier, solution than you'd normally find in an engineering lab.

"Biomimicry is about going back to our roots," Tyrrell says. "When we have a problem to solve, we have to ask ourselves, 'What would nature do?'"

The Rise of Biomimicry

Over the last few years, this approach to product innovation has quietly been building steam with manufacturers across the industry.

Qualcomm (IW 500/45), for example, has designed a new display technology that mimics the color structure of butterfly wings, resulting in low-power, sunlight-viewable tablet screens.

Airbus (IW 1000/47) already boasts an enormous list of biomimicry projects on its books, including lotus leaf-inspired seat fabrics to aid in cleaning, sea bird-inspired noses to reduce fuel consumption and emissions and, eventually, owl wing-based structures to make flight nearly silent.

Add to that existing projects like Velcro and the West Japan Railway's kingfisher-billed bullet train, and this model shows real potential in the market. In fact, some studies already are predicting enormous monetary value attached to it.

A report commissioned by the San Diego Zoo, for instance, estimates that by 2025, biomimicry could represent about $300 billion of the annual U.S. GDP, along with another $50 billion from natural resource savings and reduced CO2 pollution.

In that same time frame, it projects that biomimicry could account for 1.6 million jobs in the U.S. and add around $1 trillion in global value.

So it's no wonder that companies like Parker Hannifin have begun incorporating the process into their overall innovation programs. In the next few years, it might be a critical ingredient for success.

Pay Off

Back at that Italian cement factory, snakeskin finally won out.

After a few trials, the design team came up with a hose lined with a series of interlocking ceramic hexagrams separated by thin barriers of rubber.

It resulted in a hose that was fully flexible and, in theory at least, strong enough to survive the abrasive materials a bit longer than steel.

Parker installed a prototype of that hose in the factory six years ago to replace the pipes that barely lasted a fortnight.

That prototype is still in operation today.

"Not only is it still in operation, we actually can't find any visual signs of wear," Buca adds. "That was a big eye-opener for us."

And that kind of result isn't missed up at the corporate level.

"We constantly challenge ourselves to evolve our thinking to deliver solutions that meet the need of tomorrow and beyond," notes Parker Hannifin's Chief Technology and Innovation Officer, Craig Maxwell. "The science of biomimicry is just one example."

Innovations like these, which he calls "new to the market" and "new to the world," are quickly finding a place in the company's R&D efforts, he says.

"When you invest in ideas that result in technologies and innovations [that] make powerful impacts on humanity, you create a culture that people want to be a part of," he adds.

Following the success of its snakeskin hose, the team at Parker has begun investigating a number of different biomimicry projects, including color-changing technologies that can display the health conditions of high-pressure connections and a water filtration system based on a study of deep-diving water spiders.

It's all very exciting, revolutionary work. But it's not without its problems.

Defining a Process

"Biomimicry is a very, very misunderstood topic by most people," Buca explains. "Biomimicry, as I see it, is a process of trying to understand what the problem is that you're trying to solve and then, once you understand that, you go out into nature and find the champion organism or system in nature that has addressed similar problems."

It's not an anecdote in the design process, he says. It's a systematic methodology that stimulates the creative process.

The problem is, he says, there is no real process for this that you can use to monetize for business.

"How do you teach your people these principles and then bring them to a state where they can be actual practitioners themselves?" he asks. "When we first got started, this wasn't something you could buy a book on, it wasn't something you could take a course on. It was uncertain as to what the outcome would be, and you need mythology and outcome before it can be something you can use in business."

More on Biomimicry

"In order to invest in this as a process, there has to be a process," he insists. "That's the piece we're trying to wrestle with now."

That's where Tom Tyrrell and Great Lakes Biomimicry come in.

Over the last few years, Tyrrell has begun forging partnerships with universities across northeast Ohio to build a program to turn biomimicry into a repeatable model.

With the help of industrial partners like Parker Hannifin, GOJO, Sherwin-Williams (IW 500/107) and Ross Environmental Services, he and his team have created a Ph.D. fellowship to create new experts in the field.

"Tom [Tyrrell] has finally created a system to bring this whole thing into value," Buca says. "That's one of the reasons we're behind the organization -- we want to have a program that actually addresses not only the use of biomimicry for our advantage, but also the process itself."

In that sense, he says, the real work that will define the future of the industry is all taking place in university labs.

Up in Vancouver, Canada, one such university team is pushing that science to new heights.

Geckos in Space

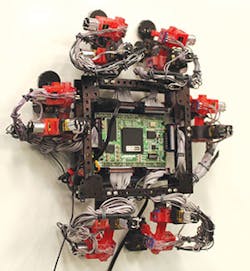

Since 2007, students working in the MENRVA research lab at Simon Fraser University have been developing a novel technique to bring wall-climbing robots to space -- a project funded by the European Space Agency and NSERC (Natural Sciences and Engineering Research Council of Canada) that is absolutely wrought with engineering challenges.

"There's no good way of sticking a robot in a space environment," explains Mike Henrey, a former graduate student of the program who helped develop the project under Dr. Carlo Menon.

"You can't use suction in a vacuum," he says. "You can't use conventional adhesives and you can't use magnets because most of the equipment is nonferrous."

Beyond that, there's the robot itself.

"Wheeled robots or track robots can get stuck on smooth surfaces," he says. "They can do inside corners, but they can't really traverse the general surface."

To overcome those challenges, the team took a two-pronged biomimicry approach.

For the robot, they designed an eight-legged arachnid structure straight out of the animal kingdom, which allows it to crawl over, on, or around any obstacle it may face.

On the feet, they developed a unique pad composed of tiny hairs measuring just a few hundred nanometers across. The hairs are so small that they are able to adhere to any surface at the atomic level, using something called van der Waals forces -- the same structure that allows geckos to climb up panes of glass or across a ceiling. The robot, it seems, now has that same capability.

To anyone outside the program, that approach might seem fairly wild and new. But to Henrey, it's all just part of the engineering process. "Biomimicry is really just an inspiration for a project," he explains. "There are still a lot of engineering calculations you have to do after you complete the biomimicry step in order to build the real engineering project."

And that is really Buca's point.

Biomimicry isn't creating a new way of design or a new way of engineering. It's a new way of thinking that needs to be interjected into an engineer's design process.

"When you're trying to design a new project, you have to get your ideas from somewhere," Henrey says. "Biomimicry is just another source for ideas, in a lot of ways. It's another tool in the toolbox."

About the Author

Travis M. Hessman

Editor-in-Chief

Travis Hessman is the editor-in-chief and senior content director for IndustryWeek and New Equipment Digest. He began his career as an intern at IndustryWeek in 2001 and later served as IW's technology and innovation editor. Today, he combines his experience as an educator, a writer, and a journalist to help address some of the most significant challenges in the manufacturing industry, with a particular focus on leadership, training, and the technologies of smart manufacturing.