Terry Ellis had already laid off half his workforce when he got a call to help manufacture face shields for COVID-19 first responders.

His company, Metalcraft Solutions in Akron, Ohio, has both essential (aerospace, medical and military) and non-essential (tire mold) customers. Ellis, the company’s general manager, had kept on 24 essential workers in the early days of the crisis and still had capacity to spare, so he leapt at the chance to collaborate.

The project, shepherded by an ad-hoc consortium called the Ohio Manufacturing Alliance, took shape the first week in April. On April 1, Ohio Gov. Mike Dewine put out a call for companies, government agencies and associations to collaborate on manufacturing personal protective equipment (PPE) for medical workers.

As state leaders scrambled to secure $5 million in initial funding for the project, advocacy group the Ohio Manufacturing Association put together a database of 1,500 manufacturers who stepped up in two days, interested in helping. MAGNET, Northeast Ohio’s Manufacturing Extension Partnership (MEP), engineered the faceshield project, finding 19 manufacturers who best fit the specs for the effort, and provided technical support to help a diverse group of companies work together.

The goal: to create an entire local supply chain and get it up and running in two weeks’ time, then manufacture from 750,000 to a million face shield kits in five weeks, to be distributed to local hospitals.

It was a tall order, and one that required some sleepless nights to coordinate: Molds for face shields are typically made in China and take six to 12 weeks to manufacture. Ethan Karp, MAGNET president and CEO, burned up the phone, going down some 40 dead-ends to finally source plastic during a raw-material shortage. “Product was disappearing and increasing in price every 30 minutes,” Karp said in an email.

MAGNET tapped into the resources of hospitals and universities as well: Case Western Reserve University and Eaton Corp. designed and built the face-shield prototypes. Cleveland Clinic and University Hospitals provided feedback on the design.

Meanwhile, Ellis had been working the phone and email himself, contacting every local manufacturing consortium he could think of to offer Metalcraft’s services in 3D metal printing, laser cutting and specialized machining. “We figured if someone brought a problem to us, we would probably be able to contribute to solutions,” he says. “So we started reaching out to everyone.”

Metalcraft Solutions had never made Personal Protective Equipment before, but specializes in 3D metal printing and had four of six 3D metal printers at the ready.

MAGNET’s head of additive manufacturing, Dave Pearson, was the first to call. “He had actually been in our shop and seen an innovative mold manufacturing technology [called material displacement] that we have the patent application in on,” says Ellis. “He thought that perhaps that technology would work well” for the rapid tooling they needed for the project.

Metalcraft was tasked with making a two-cavity insert for an injection mold for the face shield headbands. It was a stretch, as the company had never printed a piece of that particular complexity. But they found a new partner in a company down the road called Esterle Mold and Machine.

“They knew our capabilities and we knew theirs,” says Ellis. “So we called them and said, ‘How about this project?’” Esterle did the engineering for the mold, which usually takes three days, in an afternoon.

Ellis and Metalcraft Engineering Manager Todd Elwood spent the night getting the 3D printers up and running to the specs they needed. Building the inserts took four days, then required machining, finishing and polishing. Easter weekend was spent getting the inserts finished; Esterle produced the molds in a day. Early last week, they had 10,000 face shield headbands prepackaged and ready to ship.

All told, 19 manufacturers, from global corporations to tiny tool shops, have been enlisted in the project—diemakers, engineering firms, engine gasket manufacturers, toymakers (Little Tikes, which will assemble the face-shield kits that go to healthcare facilities).

“You know, there are a lot of takeaways from all this,” says Ellis. “This is really a terrible situation that we find ourselves in. And certainly, we’re pretty much the lucky ones, right? We get to stay open, for one thing, as opposed to businesses that had no choice but to shut down. And we are fighting the fight, but we are not any more at risk than anyone else who is not on the front line. People who are on the frontline are the heroes.”

The face shields, which will go to nursing homes and other healthcare facilities as well as hospitals, are just the beginning, says Eric Burkland, the OMA’s president. The plan is to enlist more manufacturers in the brimming database to produce other PPE items in high demand—from industrial sewers making face masks (“community masks” not medical grade) for returning workers to balloon manufacturers perhaps making gloves. A long list of needed items includes sample collection tubes, goggles, infrared thermometers, isolation room HEPA filtration machines.

Manufacturers are across the board in their expertise, “as we expected in a heavy industrial state like Ohio,” says Burkland. “Our biggest challenge is coordinating everyone and getting the raw materials.”

Ellis thinks the connections he’s made—one right in his backyard—might continue after the crisis is over. “We found a valuable partner in Esterle,” he says. “Now when someone approaches them and says, ‘Hey, I need this and I need it quick and I need this many parts,’ they will know, ‘Hey, there’s a technology out there that can do this. Let’s utilize it.’”

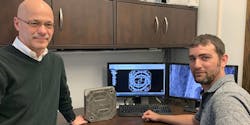

Main photo: Metalcraft General Manager Terry Ellis and Engineering Manager Todd Ellwood present their handiwork, a 3D-printed face shield headband mold insert.

Second photo: Metalcraft CNC programmer and machine operator Dillon Morehead worked through the Easter weekend.

About the Author

Laura Putre

Senior Editor, IndustryWeek

As senior editor, Laura Putre works with IndustryWeek's editorial contributors and reports on leadership and the automotive industry as they relate to manufacturing. She joined IndustryWeek in 2015 as a staff writer covering workforce issues.

Prior to IndustryWeek, Laura reported on the healthcare industry and covered local news. She was the editor of the Chicago Journal and a staff writer for Cleveland Scene. Her national bylines include The Guardian, Slate, Pacific-Standard and The Root.

Laura was a National Press Foundation fellow in 2022.

Got a story idea? Reach out to Laura at [email protected]