The Long-Term Problem of Outsourcing

The two biggest problems facing American manufacturing are the trade deficit and outsourcing. Over the last three decades, multi-national corporations (MNCs) decided that it was in the best interest of their shareholders to move jobs and production to low-cost foreign countries. According to the Economic Policy Institute, American corporations have outsourced more than 5 million jobs and 91,000 plants since 1998.

Under the flag of the free market, the public found out that there was no loyalty to the United States. Instead of trying to protect American industries and slow down the rush to low-cost countries, the only real loyalty was to the short-term interests of their shareholders.

Some of the biggest outsourcers of American manufacturing jobs include General Electric, Caterpillar, Microsoft, Chevron, United Technologies, General Motors, Ford, Georgia Pacific, Harley-Davidson, Kimberly Clark, Briggs and Stratton, Honeywell, Merck, IBM, Pfizer, and Boeing.

In terms of increased profits and decreased costs, outsourcing has really worked. An October chart from Statista shows that from 2002 to 2019, corporate profits increased 300%, from $.75 trillion to $2.25 trillion, while the rate of inflation during that span was 42%.

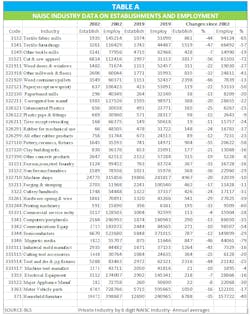

Table A shows what has happened to 38 American manufacturing industries since 2002. As you can see from the table, all 38 of these manufacturing industries have declined in terms of the number of establishments and employment.

Some of the industries such as textiles, apparel, furniture, hardware, magnetic media, computers, cutlery, hand tools, and electrical equipment have been declining for many decades and are probably beyond recovery.

But the most perplexing of these declining industries are the ones that are fundamental to making other manufactured products. These are industries like machining, machine tools, mold making, tool and die, forging, foundries and semiconductors. Table A begs the question, what can we do to stop the slow erosion and outsourcing of these industries?

The problem is that a new product or technology is invented in the U.S. and then is manufactured in a foreign country and eventually lost to that foreign country. We have invented personal computers, mobile phones, televisions, robots and a host of electronic technologies that are no longer manufactured in the U.S.

A good example of a critical industry is the semiconductor industry. Semiconductors are silicon wafers that are used as a platform to make microprocessors. They are used in the electronics, computer, and communication industries. Semiconductors are used to make chips that are used in cell phones, iPods, GPS, solar cells, light-emitting diodes, and hundreds of other consumer products. Semiconductors are absolutely fundamental to the electronics and computer industries.

Even though the semiconductor and microprocessor were invented in the United States, the semiconductor industry has been moving offshore for decades. Table 1 shows that the semiconductor industry has lost 787establishments (12%) and 149,889 workers (20%) since 2002. One of the big problems is that when the manufacture of semiconductors moves overseas, research and development goes with it. If the decline continues, the US is in danger of losing its innovative edge in electronics and computers.

The Intel Example

In my own state of Oregon, Intel is the largest corporate employer, and recently announced that they may outsource their advanced chip production to their biggest competitor, TSMC in Taiwan (the world’s leading chip fab company). U.S. chip producers account for half of the world’s microchip designs, but only 12% of the global chip manufacturing. Why? Because almost all of them have chosen to outsource their production. In fact, Intel is the only U.S.-based manufacturer of micro-processors.

In an open letter to President Biden, Bob Swan, the CEO of Intel, asked Biden to pursue a manufacturing strategy for the semiconductor industry, which, according to the Boston Consulting Group, needs $50 billion in investment to survive. So, one might ask, how did we get to this point in the semiconductor industry where the industry needs a bailout, and how many more outsourced industries will need the same?

The Short- vs. Long-Term Problem

I have been watching outsourcing since the 1980s, and there seems to be a pattern in what happens to the industries and companies:

1. It begins with a U.S. corporation seeking a cost advantage and better short-term profits by outsourcing a product (or parts of a product) to a foreign country.

2. Once the corporation realizes the cost advantage, its competitors follow suit to try and stay competitive in the market.

3. Most people don’t realize that along with the product, the critical knowledge, skills, tools and process engineering also leave with the product and the foreign manufacturer is free to find their own suppliers and sources of materials, eliminating U.S. suppliers from the supply chain.

4. After a time, foreign manufacturers are not satisfied with just making the parts and begin to seek higher value-added work or a greater share of the total product and move toward complete product assembly and management of the whole supply chain.

5. Once the foreign manufacturer has enough experience, they can do the design engineering and eventually don’t need the U.S. OEM and take over the market. So, in chasing short-term cost reductions and profits, the U.S. OEM inadvertently establishes the foreign supplier as a competitor and loses the market.

Outsourcing by American corporations has caused permanent damage to American workers, manufacturing, supplier companies, and the living standards of many families. It may lead to short-term profits for the corporation but eventually the corporation will lose the technology and the market to its foreign competitors. It is effectively handing its foreign competitors the rope to hang it with.

According to the 2019 IndustryWeek article Corporations’ New Purpose – To Serve All Stakeholders Not Just Shareholders, 181 CEOs signed a commitment letter to lead their companies for the benefit of all stakeholders, customers, employees, suppliers, communities and shareholders. They said this statement “reflects the business community’s unwavering commitment to continue to push for an economy that serves all Americans.”

But the reality is their commitment to short term profits has resulted in the de-industrialization of America. The best thing they could do to serve all Americans would be to stop or reduce outsourcing. So it is now time for them to walk their talk.

If they continue on their current path, most of industries shown in Table A will erode away. The corporations must decide whether their loyalty is to their country, or whether they have chosen to become international corporations with no loyalties and only committed to short-term profits.

Michael Collins is the author of Saving American Manufacturing and can be reached at mpcmgt.net.