By Paul Brooks, Business Development Manager, Rockwell Automation on behalf of Industrial IP Advantage

Like many words in the English language, “network” and “protocol” have different meanings, depending on the context. In the context of digital communications, Merriam-Webster defines network as “a system of computers, peripherals, terminals, and databases connected by communications lines.”

The world’s most common computing network is Ethernet, uniformly defined under IEEE 802.3. More than 85% of the world’s LAN-connected PCs and workstations rely on standard Ethernet, which allows seamless networking of electronic devices, regardless of their operating system.

Protocols, in the context of digital communications, require a slightly longer description: “For computers to exchange information, there must be a preexisting agreement as to how the information will be structured and how each side will send and receive it. Without a protocol, a transmitting computer, for example, could be sending its data in 8-bit packets while the receiving computer might expect the data in 16-bit packets.” Protocols are defined by international or industry organizations, such as the IEEE and the Internet Engineering Task Force (IETF).

Critically, the definition points out that the most essential and powerful of these technical standards is Internet Protocol (IP). The vast majority of digital developers worldwide use IP to advance information handling and task management continuously.

Conceived at the birth of the Internet itself, IP is the primary protocol that supports today’s global, multimedia information and communications system. Relying on an open-architecture networking environment — primarily standard Ethernet — IP enables the invention and interoperability of an array of electronic communication devices, many of which the Internet’s original creators could only dream.

The Powerhouse Protocol

IP provides the common electronic language that allows different devices not only to coexist on a network, but also to interoperate. IP organizes data into a common digital structure, enabling everything from computer hardware and software to cell phones and smartphones to interact and connect to the Internet.

While IP commonly is referenced as part of the TCP/IP protocol suite (TCP standing for Transmission Control Protocol), IP is the powerhouse of the pair. It implements key network functions, including addressing, packet handling and routing. IP also is the foundation that other TCP/IP protocols and numerous applications are built upon.

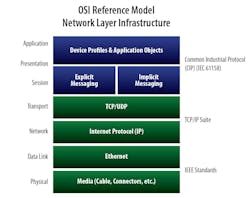

IP functions at the Network Layer (layer three) in the Open Systems Interconnection (OSI) reference model (see Figure 1). That means it runs on top of the physical and data-link layers defined by IEEE 802.3 — otherwise known as Ethernet.

Figure 1. IP functions at the Network Layer (layer three) in the Open Systems Interconnection (OSI) reference model. It runs on top of the physical and data-link layers defined by IEEE 802.3 — otherwise known as Ethernet.

These two standards are formally recognized, and their combined use is nearly ubiquitous — except in a portion of industrial automation. Traditionally, many manufacturers have relied on dedicated, purpose-built proprietary networks for plant-floor automation, with the rest of the enterprise communicating via standard, unmodified Ethernet.

This has contributed to a digital divide between plantwide and site-wide operations and the overall IT infrastructure, often creating islands of automation in the manufacturing realm. Without standard, unmodified Ethernet on the plant floor, many industrial automation companies can’t take advantage of higher-level protocols and the immense functionality they support.

Among these are functions the rest of the computing world, indeed most every industry, takes for granted, such as FTP to send files, SMTP to send an email and HTTP for web browsing. Add to that list even more recent and powerful digital communication technologies such as VoIP (Voice over Internet Protocol).

Some have been built specifically for industrial applications such as the Common Industrial Protocol (CIP™). CIP encompasses a comprehensive suite of messages and services for the collection of industrial automation applications — control, safety, synchronization, motion, process, energy management, configuration and information.

It’s important to remember that Ethernet is just a transport mechanism; it’s the upper layer protocols that ride on top of it that enable true interoperable communication. Thus, CIP provides a unified communication architecture throughout the plantwide or site-wide network infrastructure.

Standard Ethernet vs. Ethernet “Based”

With all these advantages, why haven’t all automation companies adopted standard Ethernet-enabled IP? The reasons vary, although most are rooted in the fact that the plant floor is a much more rugged and demanding environment than the average office, and its networking demands are different.

Instead of accessing files and printers, plant-floor controllers must access data embedded in controllers and drive systems, operator workstations and I/O devices. Plus, plant-floor data communications needs are real-time or very close to real time. Terminating the fill operation on a bottle requires much more time-precise communications than accessing the next page of an Internet site, for instance.

Also, in the past, standard Ethernet equipment and cabling lacked the durable, ruggedized “industrial” strength necessary to stand up to tough conditions often found on plant floors. Those reasons for resistance have been well overcome by advances such as EtherNet/IP™, which combines unmodified Ethernet, IP and CIP. Hardened hardware, ruggedized cabling and other equipment also have helped to dispel Ethernet doubts.

Still, some manufacturers have remained tied to the proprietary plant networks of the past, or they’ve been convinced by entrenched vendors that “Ethernet-based” technology is equal to standard, unmodified Ethernet. It’s not.

Derivatives of IEEE 802.3, and more importantly TCP/IP protocol suite, typically don’t come with the same capabilities. For example, manufacturers who don’t use standard Ethernet and TCP/IP technologies often can’t connect the plant networks seamlessly to the rest of the IT infrastructure without using special hardware or protocol gateway devices.

These add-on “protocol enhancements” can increase a network infrastructure’s cost and complexity. These additional items also add one more point of system configuration or failure. They also might limit the vendor supplier set and require specially trained technicians to support it. The lack of seamless connection severely limits options and innovation.

What do we mean by seamless? We mean the ability to do real-time routing outside of a Layer 2 LAN or Layer 3 subnet. Or, said another way, no data mapping!

EtherNet/IP = IEEE.802.3 + IP + CIP

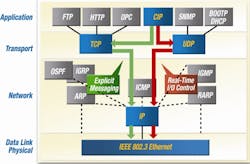

Manufacturers who rely on EtherNet/IP as their industrial network can seamlessly share plantwide information. That's because EtherNet/IP is a true IEEE 802.3 standard. It also adheres to the wireless standard, 802.11. EtherNet/IP uses the tools and technologies of unmodified Ethernet, which has steadily evolved to provide high performance network intelligence (see Figure 2). Speeds have risen from 10 Mbps to 100 Mbps to one gig and beyond.

Figure 2. This graphic shows adherence to IEEE 802.3 and IETF TCP/IP protocol suite while also illustrating that real-time communication is guaranteed.

Meanwhile, engineering enhancements have made EtherNet/IP a multidiscipline platform, converging operations with plant-floor control, motion, process and safety applications. Thus, EtherNet/IP enables organizations to save money by moving away from expensive, closed, plant-floor-dedicated networks.

EtherNet/IP provides users with the tools to deploy standard Ethernet technology for industrial applications. The result: performance and data anytime, anywhere.

In addition, EtherNet/IP's familiar Internet technology means users can learn how to operate systems connected to the network more quickly and easily. The vast majority of systems developers already are familiar with the software available for Ethernet applications. Plus, without separate networks to worry about, engineers can more simply integrate machines into the plant, significantly lowering start-up costs.

Today, more than 375 vendors worldwide offer a range of EtherNet/IP product lines. EtherNet/IP also works transparently with all standard off-the-shelf Ethernet devices found in the marketplace, and can be supported easily on standard PCs and all their derivatives.

EtherNet/IP allows users to put the full power of the Internet Protocol to work for industry, now and far into the future.

For more information on EtherNet/IP, visit www.industrial-ip.org/ethernetip.

RELATED CONTENT

- EtherNet/IP Infographic: Learn how automation meets the "Internet of Things."

- How to Implement Time Synchronization on EtherNet/IP: You can synchronize automation device clocks accurately by leveraging CIP Sync and following important design and configuration guidelines.

- EtherNet/IP: Technology Enabler for Network Convergence: Learn how network convergence between the plant floor and business offices reduces risk and costs, increases security, and boost profits.