Virtual Design: Simulated Crash Test Dummies

In the race to produce the safest, most fuel-efficient cars, automakers are turning toward high-performance computing (HPC) systems to conduct such simulations as crash tests, operating variables and parts performance, according to research developed by software giant Microsoft Corp.

Traditionally such tests have required engineers to share a single super-mainframe computer to complete jobs. But improvements made to HPC technology now allow for easier integration with existing applications, saving engineers days to process tasks.

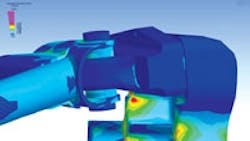

Many HPC software programs have been designed to simulate everything from aerodynamics and airbag deployment to how brake cooling occurs on a certain disc or the combustion and thermal impacts on the inside of cylinder walls, according to a recent Microsoft report.

HPC systems also could make mathematical modeling easier. "Hardware builds are now used to confirm the math rather than finding out what is wrong with the design -- a key distinction," explains Steve Rohde, General Motors Corp.'s former technical director for vehicle synthesis, analysis and simulation. "Now a supplier may provide part/subsystem math models that can be integrated directly into a virtual vehicle prior to virtual testing." Adds Rohde, who is now director of Quantum Signal LLC, a mathematics-based engineering solutions firm in Ann Arbor, Mich., "This is completely analogous to requiring hardware from suppliers at various stages in the vehicle-design process."

See Also:

About the Author

Jonathan Katz

Former Managing Editor

Former Managing Editor Jon Katz covered leadership and strategy, tackling subjects such as lean manufacturing leadership, strategy development and deployment, corporate culture, corporate social responsibility, and growth strategies. As well, he provided news and analysis of successful companies in the chemical and energy industries, including oil and gas, renewable and alternative.

Jon worked as an intern for IndustryWeek before serving as a reporter for The Morning Journal and then as an associate editor for Penton Media’s Supply Chain Technology News.

Jon received his bachelor’s degree in Journalism from Kent State University and is a die-hard Cleveland sports fan.