A Blast Furnace in China Gets Smart Tech, and Jobs Get Safer

Iron and steel are produced in extreme conditions that are hazardous to the average metal foundry worker. The manufacturing process starts at the blast furnace, which heats up pig iron or scrap metal to over 2,000 degrees Fahrenheit. Melting the scrap requires 115 million watts of electricity, generating a significant amount of noise and heat. Tons of the molten steel are then transported in a crucible lifted by a crane across the factory floor to be processed and cast, as workers communicate the ground situation to the crane operator, who does not have 360-degree ground visibility.

It’s no surprise, then, that metal foundry work often shows up near the top of “dangerous job” lists. The work can involve hearing loss, heat stress and asthma—as well as lung cancer, serious injury and in a few cases each year, death.

Transforming a Hunan Metal Foundry

The advent of 5G is helping realize the promises of a smart factory, including production efficiency and automation on the factory floor. However, industrial 5G deployments have also proven to improve the well-being and safety of employees in production facilities, not just drive business outcomes.

One such case would be the deployment of a dedicated 5G network in Hunan Valin Xiangtan Iron and Steel’s factory. Hunan Valin Xiangtan, one of the largest metal producers in Hunan, manufactures metal components for markets such as South Korea, the United States, Japan, Europe and other regions. The 5G digital transformation in the Hunan factory is driven by China Mobile, Huawei and system integrators to enable 5G use cases, such as remote crane operations, smart robots, unmanned aerial vehicle (UAV) inspections, automatic steel coil transfer, optical scanning recognition, autonomous warehousing, 5G High-Definition (HD) video surveillance and others.

The private network deployed in the factory currently consists of more than 210 5G base stations and one Multi-Access Edge Computing (MEC) room. These 5G base stations communicate with 5G-enabled end points on the factory floor, such as machinery and employee end devices like wearables.

One such use case trialed and deployed successfully is 5G remote crane operations. It has radically improved the lives of metal foundry workers.

Pre-digital transformation, operators entered the crane 10 stories above the factory floor, first climbing up narrow stairs at a 70° angle up 98 feet (30 meters), and then crossing a narrow bridge to reach the crane operation room. The operator worked long hours in a hot, noisy, dusty, isolated environment, with limited vision of the ground situation. A supervisor on the ground had to communicate with the operator through walkie-talkies, and there is a lot of stress on the operator, who must exercise judgment with limited visibility.

Integrating 5G connectivity into the cranes enables crane operators to remotely control the cranes in an air-conditioned Network Operations Center (NOC). This is done through time-sensitive networking (TSN)-supported 5G systems that enable real-time programmable logic controller (PLC) connections, as well as 5G-connected video cameras on the cranes that transmit an HD stream of the factory floor in real time to the operator.

While this 5G-enabled use case has driven significant business outcomes in the form of increased productivity (i.e., a 25% increase in processed steel per capita), it has also significantly improved the jobs of crane workers. Multiple operators can remotely control their cranes together in real time, with full visibility of the operations through seven HD cameras on each crane that stream the factory floor in real-time through 5G. This has led to improved collaboration between operators in the room.

Anecdotally, more women have joined the workforce since we implemented 5G, and we believe that is the result of the environment becoming much safer. Before the 5G implementation, Hunan Valin Xiangtan Iron and Steel had no female crane operators. Now, nearly half of crane operators are women.

Digital Factory Connections: What’s Ahead

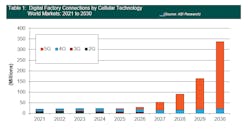

Global technology intelligence firm ABI Research predicts that by 2030, 5G will dominate global digital factory connections and have more than 317 million connections. This would eclipse all other forms of cellular connections on the factory floor; however, the inflection point for 5G is forecast to only come in between 2026 and 2027, as the 3rd Generation Partnership Project (3GPP) standards mature for industrial use cases, and the device ecosystem matures.

Beyond remote control cranes, 5G has the potential to commercialize and many other use cases across industries. Features include enhanced mobile broadband (eMBB) in allow gigabyte uploads; ultra-reliable low-latency communications (URLLC); and TSN for deterministic networking for real-time remote motion control. Massive machine-type communications (mMTC) combine with the ability of the 5G gateway to convert data protocols from different industrial transmission protocols to unify the connections of millions of end devices on the factory floor.

Moving forward, ABI Research expects more industrial use cases enabled by 5G, driving social improvement and business outcomes. For example, 5G augmented reality (AR) glasses have helped steel factory workers interact remotely with foreign technicians during the COVID-19 pandemic to commission and install equipment. Many other use cases are being trialled and deployed, including 5G-based indoor tracking of personnel and assets; 5G automated guided vehicles (AGVs) or autonomous mobile robots (AMRs) for materials handling; and 5G-based video surveillance with artificial intelligence that can detect dangerous working behavior or conditions.

Kangrui Ling, industry analyst at ABI Research, works on a wide range of projects focused on carrier strategies.