In thinking back over the highs and the lows of the 2012 U.S. Presidential campaign season, I remembered the national conversation that began after President Obama and Governor Romney’s debate discussion about the optimal mix of ships and weaponry needed to protect the interests of the country.

They didn’t say it during that debate, but what they were actually talking about is operational research (OR), a decision science that began with British military scientists inventing radar in the 1930s.

Called Operations Research (OR) in the USA and Operational Research in the UK, what we more recently call Decision Science began with British military scientists inventing radar in the 1930s. British leadership recognized the importance of this invention and asked Royal Air Force officers and civilian scientists from several disciplines to come together to figure out how to maximize this early warning so as to quickly calculate the optimal scenario of deploying their defenses.

The Americans and the British formed OR groups throughout the war trying to solve complex military operations such as logistics, combat modeling and force deployment planning. After the war, the lessons learned from applying scientific effort to make decisions in wartime translated into using and extending this knowledge in peacetime for both the government and business needs.

So OR research and development continued at a rapid pace and is defined as “the application of scientific principles to business management, providing a quantitative basis for complex decisions.”

Modern OR is not just a method but a wide range of research methods; a spectrum of research modeling and solution techniques including methods for mathematical modeling, control of optimization, simulation and scheduling processes.

This array of available methodologies enables manufacturers to identify and apply the best answers to complex planning problems.

With the software tools and packaged solutions for specific business problems available today, manufacturers are able to build models interactively, modifying constraints or variables and experiment with the effects of changes to underlying data.

For example, in mathematical optimization, a specialized modeling language enables you to work transparently and directly with symbolic problem formulations, and an appropriate solution method for the current problem can be automatically chosen. This allows problems to be formulated and solved intuitively and efficiently whether they are linear, nonlinear or quadratic.

Marketing Campaign Optimization

But so much for definitions and theories, what are some practical examples?

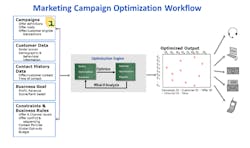

Let’s look at a marketing campaign optimization problem.

Any manufacturer has a limited campaign budget and wants the optimal return on their investments. But how do you do that?

Using OR techniques, a marketing professional can plan, prioritize and optimize customer contacts to maximize economic outcomes by making the most of each individual customer contact while considering business variables, such as resource and budget constraints, contact policies, the likelihood that customers will respond and more.

Effective consumer targeting leads to higher response rates, improved channel effectiveness and reduced spending. It also means fewer deleted emails and unwanted

direct mail solicitations. Segmentation and rules-based approaches to prioritizing marketing offers can’t come close to delivering the same results as an OR math-based approach.

Optimization delivers a quantitative prediction about the impact of making

changes to constraints, such as budget or contact policy, so you can make decisions based on facts, rather than relying on instinct. You can easily create and modify what-if scenarios to see what revenue gains are possible if the campaign budget is increased by some percentage – or to see what impact a higher contact frequency will have on customer lifetime value.

Optimize across complex contact policies to avoid oversaturating customers and violating corporate governance requirements. Eliminate uncoordinated and conflicting communications, and incorporate relevant relationship factors – such as customer risk, advertising exposure and householding – into the optimization to ensure that valuable customers receive the best possible set of communications across every channel.

Inventory Management

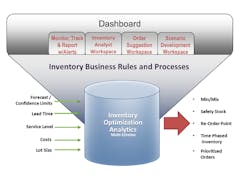

Another example is for inventory management. Inventory is a major cost for any manufacturer and resides in raw materials, WIP and finished goods so optimization through OR is important for cost control and maximal profits.

The use of OR optimization techniques for inventory is to calculates optimal inventory levels and replenishment policies based on required lead times, costs and target service levels. It identifies items that have reached reorder thresholds and generates recommended quantities for each item based on cost and service-level targets.

You can stock the right products in the right quantities, without creating excesses by rationalizing or the “bullwhip” effect. It helps produce and compare alternate planning scenarios for multiple items, thus helping select the optimal policy from a policy set.

Distribution personnel can proactively plan rather than react to unforeseen problems. Planners can customize key replenishment policy drivers to streamline replenishment for specific items.

Using scenario modeling capabilities, planners can compare planning scenarios to pick the optimal policy from a number of options. Figure 2 is high level depiction of a solution using OR capabilities to optimize any kind of inventory of finished goods.

I am sure the USA will sort out its mix of navy ships, Marine Corp bayonets and yes, even the horses in use in Afghanistan before the end of the year. In any case, we do owe the hard working military officers and scientists on both sides of the Atlantic some 60-70 years ago for the significant capabilities that OR has brought to our lives. It has helped lower costs and improve standards of living all across the globe whether it is this major Belgian pharmaceutical distributor reducing inventories yet increasing customer satisfaction, or this national auto parts chain optimizing inventory locations and prices Operations Research continues to grow in importance and use in all industries and governments at all levels.

Mike Newkirk is the Director of Manufacturing and Supply Chain Solutions at SAS.