Underinvested in Automation? Leapfrog to Smart Manufacturing!

You’re a manufacturer that has underinvested in automation or information technologies?

You’re not alone.

You get sticker shock from the traditional approach of moving information from sensors to control systems (PLC, Scada or DCS) and then to a plant/corporate information layer?

You’re not alone.

You feel disadvantaged compared to digital-leader competitors, and can’t figure out how to catch up?

You’re not alone.

Two routes to Smart Manufacturing and Industry 4.0

Great news for all of you with under-instrumented or legacy control systems! IIoT and allied technologies have evolved to a point that they now offer two innovative, lower-cost routes to Smart Manufacturing – using existing layers and new wireless technology.

The cost savings are significant; achieving a digital visibility layer can be a mere fraction of the investment of just a few years ago. True, the end results won’t be identical (the difference is in the control systems), but it is certainly possible, at a remarkably low cost, to achieve a level of digital-age visibility that super-charges an old-style manufacturer into Industry 4.0 decision-making and performance.

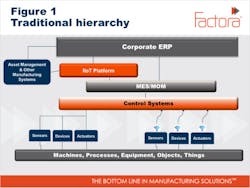

Route 1: Traditional hierarchy

In Figure 1, IIoT provides a better, faster path to Smart Manufacturing. In this approach, current and new (wireless) instrumentation are brought into the control layer, then to the MES, and from there to IIoT.

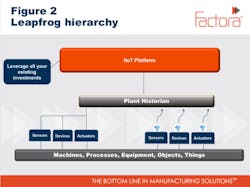

Route 2: Leapfrog hierarchy!

In the Leapfrog approach [Figure 2], IIoT enables a cost-saving shortcut (thanks to today’s cheaper sensors, cheaper wireless networks and secured connectivity to IIoT platforms), by allowing most new non-closed-loop measurements to bypass the control systems. Instead, they’re fed directly into the plant historian. IIoT picks up data from there.

This route offers significant benefits:

- Rip-and-replace is neither necessary nor justified

- Your IIoT platform gets information from existing as well as new investments.

The result? IIoT-enabled visibility and insights into your operation, in real time. Bonus: Later on, these can be used to implement advanced applications (analytics, augmented reality, and so on) – using the same IIoT platform.

This route to Smart Manufacturing boasts a long list of advantages:

- Faster to implement

- Variety of data sources (from different functions) integrated into same platform

- No need for large upfront investments; start small and scale as needed

- Use quick wins; build on successes

- Sensors can be added around critical processes to give deeper insights

- Flexibility – IIoT platforms can be implemented on-premise or at corporate data centers. Some IIoT platforms offer hybrid solutions that allow mission-critical info to stay on-premise and other info in the cloud.

Think big, start small…

For the Leapfrog route, we see major advantages to an approach we call:

Think big, start small, show success, scale fast

The first focus is on visibility, to give insights to enterprise-level decision-makers. Now, they can identify and analyze KPIs for each of the major functions. At Factora, our strength in UX (User eXperience) helps us to deliver these insights to a wide range of leadership positions.

Relatively small investments generate big returns with “Think big, start small.” And the new visibility alone – the questions it raises and the what-if debate it generates – is a strong start to the transformation journey.

Once the new visibility and insights are used to drive business decisions (“show success”), a scale-up effort can build deeper granularity, additional breadth, and more automation. Additional capabilities in analytics, machine learning and AR can be justified and built.

How do you time your technology change?

Since the world began moving to digital, manufacturing leadership has repeatedly had difficult technology decisions to make. Wait for lower prices? Wait for the next, improved version? Or jump now? The answer is rarely obvious, and becomes ever more difficult as the pace of change increases.

IIoT to the rescue! This leapfrog approach is of great benefit to any manufacturer still dealing with under-instrumentation or legacy control systems. With a minimal investment, such a manufacturer can leap to the new digital-age visibility that leads to better decision-making, improved performance, and world class manufacturing.

About the Author

Charles Horth

Chief Executive Officer

Charles A. Horth is the Chief Executive Officer at Factora, a company of manufacturing consultants who use software to help factories achieve their full potential by raising the visibility of key information on the shop floor so that plant management, employees and company leadership can run more efficient manufacturing systems.

Over the past two decades, Charles has served manufacturers throughout the globe in virtually every industry including pulp and paper, food and beverage, aluminum, glass, mining, consumer packaged goods, automotive and ethanol.

In 2013, he was one of the architects behind the successful merger of System Technologies for Industry and SlimSoft Solutions and the ensuing creation of Factora. He currently serves on the board of MESA (Manufacturing Enterprise Solutions Association).

For more information on Charles and Factora, visit www.factorasolutions.com or check out his LinkedIn profile here.