Returns Management Processes Can Drive Up Logistics Costs

Returns management is often considered a process that has little effect on the enterprise as a whole. Yet evolving competitive and customer pressures as well as increasingly complex environmental regulations have made the establishment of formal returns management processes a priority for some organizations.

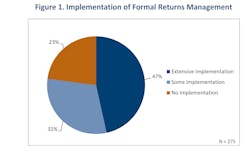

Returns management involves such practices as recycling, materials substitution, reuse of materials and waste disposal, as well as refurbishing, repairing and re-manufacturing returned products. According to APQC’s Open Standards Benchmarking Logistics, 78% of responding organizations have adopted formal returns management practices to some degree (Figure 1). Nearly one-quarter of responding organizations have no formal returns management process at all.

To gain insight into the effects of adopting formal returns management practices, APQC compared the logistics performance of organizations with three different degrees of returns management process implementation: extensive implementation, some implementation, and no implementation. The results indicate that having formal returns management practices is associated with a higher cost for managing logistics and warehousing. However, organizations should consider whether product reuse or refurbishment could result in additional revenue that would justify the potential for higher logistics costs.

Logistics Costs

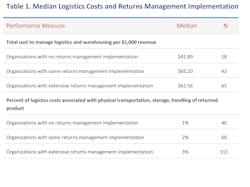

APQC’s data show that organizations without returns management practices spend less to manage logistics and warehousing per $1,000 in revenue than organizations that have implemented these programs both to some degree and to an extensive degree (Table 1). These results could be affected by greater logistics costs associated with the physical transportation, storage and handling of returned products.

As Table 1 indicates, organizations with some returns management implementation have 2% of their logistics costs associated with this process at the median, and organizations with extensive implementation have a median of 3% of their logistics costs associated with this process. However, organizations without formal returns management practices have a median of 1% of their logistics costs devoted to the transportation, handling and processing of returned products.

The difference in cost between organizations with no returns management practices and organizations with extensive implementation of formal returns management is nearly $20 per $1,000 in revenue at the median. This can mean significantly higher logistics costs for organizations with these practices.

For example, an organization with $5 billion in revenue annually and extensive returns management process implementation would spend $307.8 million annually to manage logistics and warehousing, and an organization with the same amount of revenue but without formal returns management practices would spend $209.5 million annually for the same function. That means an organization of this size could potentially have over $98 million in logistics costs associated with adopting a formal returns management process.

APQC’s data indicate that organizations with formal returns management processes spend more to manage their logistics and warehousing functions and also see a larger percentage of their logistics costs dedicated to managing and processing product returns.

The potential difference in logistics and warehousing costs related to returns management practices is no small amount. However, organizations considering implementing these practices should give thought to whether the potential results of these programs—the refurbishment or re-manufacturing of products into other usable products—would generate additional revenue that would offset the cost of returns management. This would depend on an organizations’ industry as well as any regulatory requirements the organization would need to consider. It may be that a formal returns management program would be worth the potential for additional costs.

Becky Partida is a research specialist, supply chain management, with APQC, a member-based nonprofit and one of the leading proponents of benchmarking and best practice business research.