Procurement Best Practices: Are You Achieving Best Value?

Procurement behavior is evolving as progressive corporations shift their focus from price-per-piece to concentrate more attention on total cost of ownership (TCO) and best value. C-suite decision-makers who embrace these procurement best practices will lead the way to real savings, improved productivity and stronger financial performance.

The shakeup of decades-long procurement patterns has begun with heavy industry, including the mining, metals and paper businesses. The trend is emerging in high-process industries like the food manufacturing sector. Chemical and refining companies, which face unforgiving penalties for downtime, also are early adopters.

Rewards of TCO

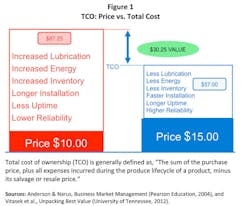

Price always will be an important factor in procurement decisions, but other considerations are receiving increased emphasis, including TCO. TCO takes into account hidden costs associated with buying, maintaining and disposing of a product during its lifecycle (see Figure 1).

Often the most important consideration in TCO-based procurement is the reliability of the part or component. Suppliers should be able to document the expected duration of their product’s lifecycle between repairs, helping clients to translate this data into reduced maintenance costs and opportunity cost associated with decreased downtime.

Product reliability facts and figures also should be readily convertible into quantifiable results related to productivity. Higher quality parts often enable increased machine speed, especially when optimized through proper lubrication and precise alignment—variables which can be monitored and adjusted in conjunction with a skilled supplier. For instance, one Russian manufacturer increased annual production 4% and saved 19 million rubles (US$600,200) after upgrading a machine component and implementing proper maintenance practices.

Progressive procurement teams also apply TCO metrics to factors such as on-demand delivery and logistics efficiency. They also will associate a value with how the supplier’s product or service contributes to energy conservation and waste reduction. For example, when one Argentinean food producer changed to “greased-for-life” rotating parts, it reduced scrap and associated grease contamination by 18%. In another instance, a U.S. manufacturer saved $247,500 annually by replacing old parts with energy-efficient components.

TCO-oriented procurement practices also seek to reduce inventory carrying costs through not only supply chain efficiencies but also use of common parts across a variety of plant applications. This broad-spectrum vs. application-specific approach streamlines the procurement process, lowers TCO and simplifies parts management from a systems perspective.

Best Value as a Procurement Priority

In a 2012 white paper, the University of Tennessee’s (UT) Center for Executive Education said the concept of “best value” goes a step beyond TCO in that it “compares alternative solutions based on value derived, not simply on cost.” A best value approach to procurement takes into account intangible values such as market opportunities, social responsibility, responsiveness and flexibility, according to the researchers.

“It’s harder. It takes more time to go through and think about what value actually is and how you want to quantify value,” says Kate Vitasek, a faculty member with UT’s Center for Executive Education and lead author of the white paper. “It’s much easier to determine which part is the cheapest. It takes more time and effort to understand the value associated with that part, and to consider how you only have to replace [Supplier A’s] part one in every four times you might have to replace [Supplier B’s] part.”

The Manufacturers Alliance/MAPI recommends companies consider all types of procurement as they would IT investments, in which the lifespan of technology and terms of support play a big role in procurement negotiations.

To achieve best value, corporate leaders must support their procurement departments’ evolution from a “price mentality” to a “price model” approach. “Some procurement departments have metrics based on purchase price variance,” says Vitasek. “Sometimes we actually have personal measures of procurement that are counter to the success of TCO and best value philosophy.”

In some cases, procuring products that offer the best value, even at the factory parts level, can contribute to higher quality in the end product. For example, one Japanese manufacturer changed to higher quality rotating parts for plant machinery, and as a result, reduced variation in machine operation. This reduction in variance increased final product quality by 1% and saved the company 3.25 million yen (US$32,690).

Corporate leaders who embrace best value and TCO for procurement add a powerful weapon to their fight against global competitive pressures because they are better able to meet mandates for increased productivity and greater profitability. By making these procurement best practices a part of their standard operating procedures, businesses win both immediate results with productivity boosts and long-term lowered costs.

Vitasek and her colleagues sum it up well in their white paper: “Buyers and suppliers should develop a pricing model through a best value lens, striving to understand profitability levers that can add value for the buyer through increased revenue, reduced risk, improved working capital and capital investment productivity, or anything else that positively impacts a company’s productivity.”

Bill Moore is senior vice president, sales development and channel management, SKF USA Inc.