Last week I had a meeting with a prospective client who said he needed some help with supply chain management. The problem as described to me by the VP of Global Operations at this well respected technology company was quite simple, “My product lead times are too damn long... my whole supply chain is too damn long.” So in traditional consulting fashion I asked a few, not especially difficult questions like, “How long are your product lead times?”, and the ever important, “How long do they need to be?”

So why do we call these things supply “chains” anyway? I grew up in a fairly rural existence where a chain was a pretty essential thing to have around. Whether it was towing a friend’s broken down pick-up or pulling out an old stump with a tractor, I never once recall worrying about a chain being too long.

The physical analogy of a long, interconnected set of supplier operations that eventually lead to the shipping of a finished product was first popularized by Keith Oliver at Booz Allen Hamilton. The obvious, simplistic likening of a supply network to a chain has a certain logical appeal that is not lost on me, although it was actually quite revolutionary at the time. But why did he call it a chain? Why not a supply rope – or better yet, how about a supply spring, or perhaps a supply fabric?

I think many of our prospective clients would suggest that the choice of “chain” is extremely appropriate as it is the one thing tying them down, holding them back and keeping them from breaking free to large sales and market share gains. Contrary to what Mr. Oliver may have intended, his now ubiquitous term supply chain has become a catch all, a buzz word, a misnomer, an excuse and a crutch. But before I flout well established convention and reexamine his choice of words, let us first examine the pros and cons of the now institutionalized analogy of supply networks to the physical properties of a chain.

As is the case with a physical chain, a supply chain tends to be only as strong, and as reliable, as its weakest link – so points to Mr. Oliver on this one. It is also fair to say that a pull signal travels from one end of a short chain to the other faster than that same signal travels through a very long chain, which is also consistent with the behavior of most supply networks. But perhaps this is where the analogy ends, or at least should end. The links of a chain have but two physical connections: a single link on the input and a single link on the output, hardly representative of the way our supply systems work today. When the chain is working, its links can rub together while they are, in effect, pulling against each other. This rubbing and pulling cause friction and in extreme cases a lot of heat – so Mr. Oliver is actually looking more thoughtful on his word choice by the minute.

Supply Chains Are Not Linear

But there are so many behaviors of the supply chain, and descriptors of supply chain performance, that aren’t particularly appropriate to the chain analogy. For one thing, a chain is almost always a serial, mostly linear device when it’s in use. But supply chains tend to have many different points of intersection going off in many directions and they have even more points of interaction. The analogy to a chain, which I contend we have all been a bit too accepting of, would be slightly more appropriate if we all bought/built a very limited set of goods, sourced our raw material from a single supplier, and sold our product to a single buyer. But this is not the way most of our world works today.

Perhaps my biggest problem with the analogy of a chain is the well-established bullwhip effect which I see manifests itself every single day in our clients’ supply networks. For those of you familiar with the effect, you have to agree that it is certainly not an effect that one could easily produce with a chain. A good, sturdy chain is just not flexible enough to really get that bullwhip action going – and unlike today’s supply networks, a chain does not try to second guess the load that’s being placed on it.

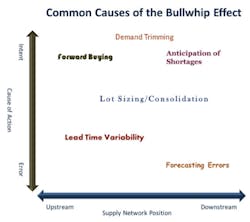

Figure 1: The bullwhip effect on demand signals in a supply network – let’s see you try this with a chain.

The tendency of all supply network participants to do more than simply react to a demand signal without any applied intelligence is probably the biggest shortcoming of the chain analogy. The progressive application of analysis, intelligence (or occasionally the lack thereof), and the second-guessing applied to incoming and outgoing demand signals by the countless participants gives the supply network a dynamic character that seems befitting of a more biological or anthropological analog.

Supply chains are highly adaptive organisms, and recent innovations in information technology have made them even more so. Many supply network participants have become far more responsive with the application of new tools and systems, although these advances have not been universally adopted. The differing level of tools and systems used occasionally amplifies the information asymmetry that exists between various supply network participants.

The concept of various participants responding very differently to the same inputs because of information asymmetry requires us to think in terms of not only an organic analog to replace the term chain, but an analog that reflects intelligence and learning - as well as a propensity towards unilateral, self-interest seeking action, and misplaced superstitious learning.

Shortage Gaming and Demand Trimming

One of the behaviors of supply networks that I find most revealing of their underlying organic nature is the far too common practice of shortage gaming. One of the five generally recognized operational causes of the bullwhip effect in supply chains, shortage gaming is the practice of inflating demand signals in order to secure a greater quantity of material or parts that are in short supply. This is clearly a thoughtful, responsive behavior (although generally unhelpful and problematic) from an organic entity with decision-making capabilities – not the perfectly predictable response of a purely mechanical system which is the way we all too often think of our supply chain.

Another organic behavior in the supply chain that contributes to the bullwhip effect is the process of demand trimming, which is generally done by supply chain participants with a combination of high working capital requirements and low margins. This process involves the intentional loading of less demand than what is requested by the firm’s customer in an attempt to counteract the perception (or reality) that the customer is driving an artificially high demand signal to the supplier.

Figure 2: Common causes of the bullwhip effect in supply chains, the majority of which are driven by specific decisions and the intentional actions of supply chain participants – not a purely mechanical response to inputs.

In the perfect scenario of demand trimming, which actually happens more often than one might think, the higher margin customer firm pads their demand by 10% or so to insure that they can meet highly profitable, un-forecasted upside demand should it materialize. The lower margin, higher working capital supplier receives the customer’s demand and intentionally loads demand at just 90% of the customer’s demand, assuming that it is too aggressive or overstated.

Both supply network participants are acting with thoughtful intent in a manner they think appropriate to protect their own interests. In this particular example, the demand trimming action ended up being quite benign, but this is not generally the case. When demand trimming decisions turn out to be horribly wrong, the entire supply chain can be thrown into a “load and chase” upheaval and occasionally lawyers show up to “help” sort things out.

When I was leading a more rural existence in my youth, I occasionally witnessed the failure of a chain – meaning it broke. But I don’t ever recall a chain breaking or failing to function because one of the links in that chain made a bad unilateral decision. And I never remember lawyers showing up to help figure out why the chain failed to perform as expected.

Sure the term supply chain has become ubiquitous in most industries and it’s based on a simple analogy that everyone can understand. But let’s not take that analogy too literally and delude ourselves into thinking that supply networks are simple mechanical systems that respond to their inputs with near perfect predictability. Supply networks contain people, and those people are increasingly supported by analytical tools and decision support systems that allow them to analyze, model, second guess, post process, modify and communicate the inputs that they receive in all new and exciting ways. Yes, it’s all linked together – but as a recovering country boy, I can assure you that the supply network that I deal with every day is anything but a chain. Sorry, Mr. Oliver. Now, can you help me get my truck out of a ditch?

Contributing Editor Ron Keith is chief executive officer for Riverwood Solutions, a supply chain consulting and managed services firm.

About the Author

Ron Keith

Chief Executive Officer

Ron Keith brings more than 24 years of operations experience to Riverwood Solutions including engineering, manufacturing and executive management positions at Westinghouse, Wavetek, Rockwell, Alcatel and Flextronics International. Ron has a reputation as an innovator, team builder, creative problem solver and strategic thinker who delivers straight talk and strong results to Riverwood's clients. He has run international EMS operations with annual sales in excess of $1.4B and has managed manufacturing, product development, and program management personnel in numerous countries.

Ron has advised more than four dozen companies on their manufacturing operations, supply chain, and outsourcing strategy including more than a dozen Global Fortune 500 companies. He has previously consulted for four of the top 10 EMS (Electronic Manufacturing Services) companies and has advised hedge funds, private equity funds and strategic investors on a number manufacturing services related investments. Ron has published more than 30 articles on various manufacturing, technology and business related topics including strategy, operations, quality management, technology trends, and supply chain management.

Prior to founding Oreamnos Partners and Riverwood Solutions, Ron served as Vice President and General Manager at Flextronics International, where he started and ran several divisions in both the EMS and ODM (Original Design Manufacturer) spaces during his more than eight year tenure. He worked with, and ran manufacturing operations for, a number of leading OEMs at Flextronics including Cisco, Motorola, JDS Uniphase, Nortel. W.L. Gore, Kyocera and others.

Ron has undergraduate degrees in both Electronic Engineering and Manufacturing. He received an MA in International Management and an MBA in Operations Research from the University of Texas at Dallas, where he also completed the majority of coursework towards a Ph.D. in Organization, Strategy & International Management (OSIM).