3D Printing: Customers Taking Charge of the Supply Chain

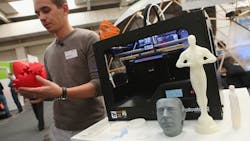

The demand economy is disrupting every sector and causing those in the supply chain and manufacturing fields to be more innovative than ever before. A decade ago, consumers accepted waiting a week for their product but now with the infusion of companies such as Amazon and Alibaba, consumers are making their purchase decisions based on how quickly they will receive the product. In order to stay competitive in the marketplace, companies are turning to 3D printing to create their products quicker.

While it is true that manufacturing in certain locations can be low-cost, managing a global logistics network is not, especially as transportation costs continue to rise. That is where the opportunity for 3D printing lies. It is not surprising that analyst firm Canalys anticipates that the worldwide market for 3D printers and its associated materials and services will grow to $20.2 billion by 2019.

Supply chains are about to make a fundamental shift. Where traditionally supply chains followed something like the SCOR model (plan, source, make, deliver, return), 3D printing is innovating that model and putting consumers in the driver’s seat.

Make: 3D Printing Means Social Media

Globally, 3D printers seem likely to follow the same trajectory as mobile phones: many countries skipped installing expensive landlines and went directly to mobile technology, which requires less infrastructure investment and is more flexible and easier to upgrade. As with mobile technology, 3D printing means low infrastructure requirements, more mobility, more programmability and more adaptability. This means nearly all of the 95% of world consumers that live outside of the U.S. will eventually access technology superior to our current production systems.

The two technologies—mobile technology and 3D printing—go together. Consumers will demand the ability to use their mobile devices to customize goods with nearly instantaneous delivery, and that means online presence, social media and analytics. Very few manufacturers right now have a social presence, meaning that the 3D printing revolution will likely continue the shift of power toward retailers like Amazon that already have online ordering systems popular with consumers.

Deliver/Return: Rise of the Robots

The 3D printing revolution also means the advance of robots, especially delivery drones and artificial intelligence. The first automated urban drone package delivery happened on March 25th. TraPac LLC’s Los Angeles terminal already has two dozen robots moving containers. Even formula racing is starting a Roborace division later this year. In addition to automating repetitive and detail-oriented tasks, robots and drones need less infrastructure and require minimal waste. Reliance on human drivers means having a vehicle big enough to carry the human, at which point investment costs require greater economies of scale by accumulating enough packages to pay for both truck and driver.

Drones can be sized just big enough to transport a package. Self-driving trucks will still require highways, but smaller, airborne drones delivering the “last mile” will mean reduced congestion, faster deliveries, and less expensive infrastructure to maintain—not to mention other benefits like delivery straight to the customer rather than to a physical address.

Source: Gets a Lot Easier

Today’s supply chains suffer from global sprawl, with months required to design and source components, and then assemble them into a finished product. Much of the time and expense in supply chains derives from the need to negotiate with and monitor suppliers. All this is made worthwhile due to the benefits of accessing specialization and competitive advantages from around the world.

The specialization and economic benefits of globalization become outdated in a world where a 3D printer and some spools of wire or other generic inputs can make nearly any desired product relatively quickly. Generic inputs require far less negotiation and planning. They also do not become obsolete and the quality is standardized, meaning that there’s less need to monitor supplier performance. Since nearly all value is added by the 3D printer and inputs are relatively low value, standardized commodities, Just in Time Inventory (JIT) and other inventory reduction approaches will be needed less.

Plan: The Consumer Takes Charge

3D printing’s most amazing impact will be how it puts consumers in charge of the supply chain—and most companies are not ready. The old supply chain reference models put the company in charge of nearly the entire supply chain: developing new product offerings, sourcing all components, overseeing manufacturing and assembly, and finally distributing products to the retail level. The customer only gets to order the product after all the work is done, choosing among available offerings. In this model, companies take a huge gamble on whether and how many of a product they will sell, leading to waste and diminished profitability.

3D printing means a greatly simplified, highly responsive, and infinitely flexible supply chain fulfills the order. In the future supply chain, the customer places the order first, and then a local, highly automated 3D printing shop produces the finished product and then delivers it, often via drones. Rather than plan, source, make, deliver, and return, a future supply chain model will start with the consumer order which will initiate make, deliver and return.

The demand economy is disrupting every sector and when paired with the advent of 3D printing, is a true game changer for the manufacturing industry. It should be a warning sign for companies that if they don’t innovate their supply chains, they may become irrelevant as consumers will have more control of the production of their own products.