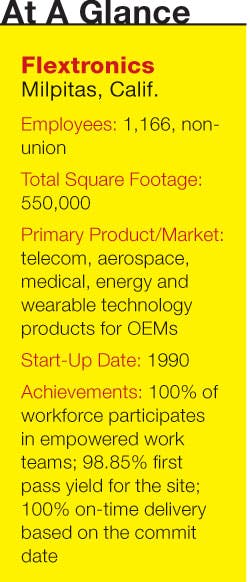

2013 IW Best Plants Winner: Flextronics -- A Partner in Manufacturing Excellence

It's a brisk December day in California's Silicon Valley, and at Flextronics' Milpitas campus, a multitude of activities are underway with similar brisk efficiency.

In one building, Flextronics employees assemble solar panels for customer SunPower Corp. In another, a sourcing team meets with colleagues from India -- and located in India -- via visual communications technology that all but places the two teams in one room rather than an ocean apart.

At a third building, engineers test the dexterity of several recently acquired robots and also work to boost the capabilities of a homegrown automated guided vehicle system.

Similar -- and dissimilar -- industriousness can be observed in the seven additional buildings that comprise the Milpitas campus. The reason behind the industriousness is quite straightforward: the customer.

"Our quality is our customers' quality. Our performance is their performance," says Paul Henningsen, senior director of strategy and planning.

Its role as a partner in new product introductions spells both challenges and opportunities. In 2013, for example, the Milpitas campus processed an average of 45 engineering change orders per day. Significant low-volume and customer prototyping work call for innovative supply-chain solutions. And because speedy time-to-market launches are critical to customers, they are critical to Flextronics as well.

Indeed, on that brisk December day, among the teams at work in Flextronics' Improvement Idea Hub was one dedicated to reducing lead times in setting up new customers. (Meanwhile, it is also hard to miss the 80-foot-long value stream map sprawling across a far wall.)

Lean and Six Sigma both contribute to driving excellence across the Milpitas operations, as does a commitment to automation. The company sets its sights on improvement projects that contribute 50% gains. Not only do such big goals inspire out-of-the-box thinking, says Anand Pradhan, Flextronics senior director of business excellence, but they are in keeping with the disruptive types of technology leaps Flextronics' customers aspire to.

And on the topic of customers, Zahid Hussain, vice president of operations for the Milpitas campus, explains the crucial role customers play in creating a culture of excellence at his location.

"We have a hundred cultures because of the customers," Hussain says. "We enable them to succeed, and we learn from all of our customers every day."

Read more about 2013 IW Best Plants winners.

See the IW Best Plants winners at the 2014 IW Best Plants Conference.

About the Author

Jill Jusko

Bio: Jill Jusko is executive editor for IndustryWeek. She has been writing about manufacturing operations leadership for more than 20 years. Her coverage spotlights companies that are in pursuit of world-class results in quality, productivity, cost and other benchmarks by implementing the latest continuous improvement and lean/Six-Sigma strategies. Jill also coordinates IndustryWeek’s Best Plants Awards Program, which annually salutes the leading manufacturing facilities in North America.

Have a story idea? Send it to [email protected].