IW Best Plants Winner Texas Oil Tools: Manufacturing Excellence on a Budget

With plenty of money and consultants analyzing every operation, boosting factory efficiency sounds easy. But, that kind of spending isn’t always an option, especially for small- and medium-sized manufacturers. So, what can you get for a few thousand dollars and a workforce committed to continuous improvement?

How about these three-year results:

- Workplace injuries eliminated

- Double-digit improvements in on-time delivery

- Halving already low scrap rates

- Reducing inventory levels by $17.5 million

The spend for NOV Texas Oil Tools, a 130-person machine shop, to achieve those gains? A few equipment upgrades, about $5,000 for TV screens to share production data throughout the plant, a workforce committed to continuous improvement.

Without a massive budget at its disposal, Texas Oil Tools made the grade holistically—rededicating itself to safety, cost reductions, quality improvements and operational efficiency in virtually every department.

The big thing that had been standing in the way of improvements was time. Rearranging a machine shop to improve workflows is nearly impossible when orders are flowing. Oil prices plummeted at the onset of the COVID-19 pandemic, and Texas Oil Tools’ orders disappeared. Painfully deep layoffs followed, but the crisis provided the opportunity to reconfigure the shop floor for increased productivity, improve warehousing operations to lower inventory costs and engage employees to improve safety.

Embracing Cells

In 2020, Texas Oil Tools used a traditional machine shop layout—lathes next to lathes, mills next to mills, one operator per machine. CNC machinist “Super” Mario Perla says the process inflated work in progress.

“You’d have parts that needing milling and lathe work,” Perla says. Lathe operators would batch dozens of parts together, then they would often sit for days until mill operators were ready for them.

The continuous flow allows one machinist to finish components without waiting for parts from another line. Eliminating waiting times boosted on-time delivery by 20 percentage points throughout three years.

Texas Oil Tools had experimented with cells pre-pandemic with one three-machine operation. With the floor mostly idle in 2020, crews rearranged equipment to create 11 more cells. No investments in automation, no expensive new equipment, no complex pallet systems. Just forklifts to move decades-old CNC machines and teamwork to optimize layouts.

People Drive Success

While the lack of work resulting from plunging oil prices allowed process improvements, the sting of layoffs forced remaining employees to question the future. Davis says workers needed some wins to boost morale.

To hear more from Sandvik Coromant and other IW Best Plants winners, attend the Manufacturing & Technology Show from Oct. 18-20 in Cleveland. All four winner's of this year's awards will participate in a panel discussion on Oct. 19 to discuss how they approach continuous improvement and strive toward manufacturing excellence.

The facility’s pre-pandemic safety record of roughly one accident per year already was better than industry average, but that number can always improve. So, Texas Oil Tools created an employee committee that collects suggestions and concerns from co-workers and studies ways to address those.

“We just listened to everyone’s ideas and picked the projects that sounded like they had the most potential,” Setia says.

In August 2022, the plant was 1,059 days accident free.

Davis says putting employees in charge of the safety committee encouraged people in harm’s way to find better ways of doing everything.

“Excellence in safety has other benefits. The attention to detail that you need to get to zero accidents leads to lower scrap and lower waste overall,” Davis says.

Focus on Results

That comment sums up Davis’ mixed approach of empowering people and tracking classic continuous improvement metrics. He can point to individual employee contributions to statistical improvements and evaluation metrics that changed workers’ attitudes.

Some gains were top-down from management. Texas Oil Tools developed better statistical tools to improve demand planning, allowing that $17.5 million inventory reduction. Warehouse changes placed stringent targets for positional accuracy of every tool, workpiece and block of material.

Others gains involved trusting people and getting out of their way. Management removed time limits on setting up certain machining operations, trusting employees to do the job right and not waste company time. Scrap and rework costs fell 52% from already low levels, and setup times didn’t change significantly.

That constant embrace of people, teamwork and culture—well, this is Texas, so it all comes down to barbecue eventually. Several times throughout the year, teams compete against each other for the best smoked brisket and beef ribs, friendly contests that lead to everyone getting fed. It might sound a little corny, but Davis calls sharing meals a Texas Oil Tools best practice.

“You’ll have engineers and salespeople sitting down with machinists and testing people,” Davis says. “When people talk to each other across department lines like that, that’s when you get the best ideas.”

NOV Texas Oil Tools

Conroe, Texas

Employees: 136

Primary Product: Oilfield safety equipment

Startup Date: 2012

Achievements: Zero accidents in nearly three years; more than 50% reduction in inventories in the past three years; 50% reduction in scrap in the past three years; 14-week turnaround time on service jobs, down from 28 weeks; reshaped the factory floor, launching 12 manufacturing cells in three years.

Blowout Preventers

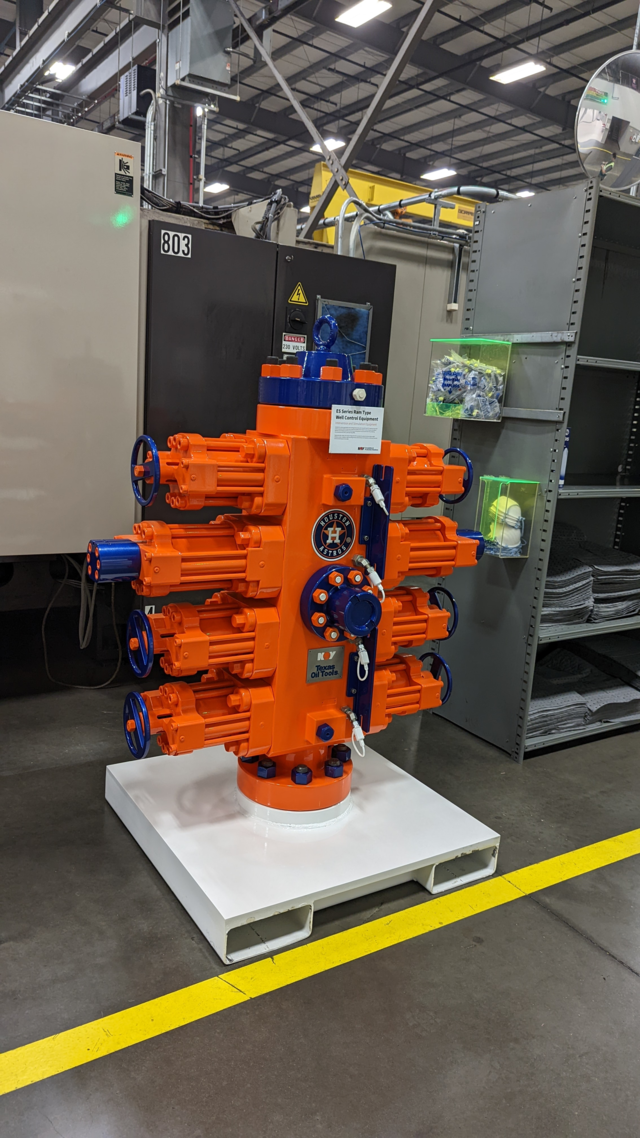

This Texas Oil Tools' quad-stack blowout preventer uses four hydraulic rams to protect people and the environment in case of disaster on drilling sites. The blue and orange color scheme is to support the Houston Astros.Robert Schoenberger

This Texas Oil Tools' quad-stack blowout preventer uses four hydraulic rams to protect people and the environment in case of disaster on drilling sites. The blue and orange color scheme is to support the Houston Astros.Robert SchoenbergerTexas Oil Tools makes wellhead pressure control equipment with the primary product being blowout preventers (BOPs), devices that save lives and prevent environmental disasters. In oil and gas drilling, coiled steel tube feeds into the wellbore to eventually carry hydrocarbons to the surface. If drill bores hit pockets of pressurized gas or liquid, those can travel up the pipe to the drilling rig, putting people and the environment at risk. A series of hydraulic rams (typically four) on the BOPs stop the coiled tube from moving into the well, trap the pressure underground, shear the pipe and seal the system. Blowouts are rare, so the plant’s products almost never get used. However, when needed, they must be absolutely reliable. So, the American Petroleum Institute mandates 100% testing for incoming materials and 100% inspection for many machined components on BOPs.

About the Author

Robert Schoenberger

Editor-in-Chief

LinkedIn: linkedin.com/in/robert-schoenberger-4326b810

Bio: Robert Schoenberger has been writing about manufacturing technology in one form or another since the late 1990s. He began his career in newspapers in South Texas and has worked for The Clarion-Ledger in Jackson, Mississippi; The Courier-Journal in Louisville, Kentucky; and The Plain Dealer in Cleveland where he spent more than six years as the automotive reporter. In 2014, he launched Today's Motor Vehicles (now EV Manufacturing & Design), a magazine focusing on design and manufacturing topics within the automotive and commercial truck worlds. He joined IndustryWeek in late 2021.