The Best Investment a Company Could Possibly Make

According to one definition, an investment is “an asset or item purchased with hope that it will generate income in the future.” In finance, an investment is seen as a monetary asset purchased with the idea that it will provide income in the future or be sold at a higher price.

My definition, however, based on The Toyota Way teaching and my own experience, is quite different. The best investment is time dedicated to develop talented people to use their potential the best, Lean, way, with the idea of reaching the company goals. Their skill improvements will lead to more value-added activities, thus higher efficiency and better productivity, thus more income; moreover, it will create a company rich with highly professional and satisfied people. The following case study illustrates this point.

Intercar is based in southern Italy and was founded about three decades ago. It specializes in selling and repairing equipment. In 2001 it was given the opportunity to be an exclusive Toyota Material Handling dealer. Having started working under the influence of Toyota’s methodology, it marked a milestone for the company’s cultural and operational prosperity, corporate philosophy and the time when their biggest investment was made.

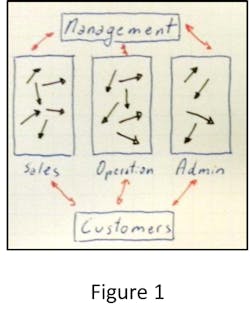

Prior to this, the company was organized in three main silos: sales, operations and administration—all three connected with management and customers directly, but they were not mutually intertwined (Figure 1). Within their own departments, employees were performing tasks in their own way, each tackling their own obstacles daily. Results? Sales representatives were waiting for customer requests for quotations and potential orders; purely reactive operators were repairing and maintaining equipment solely upon requests; and administration was responsible for staff functions like accounting and scheduling. All in all, it was working well enough to make the company profitable.

A big wake-up call came when a significant recession occurred in 1998. It hit the company hard with a severe reduction in sales and maintenance orders and required immediate reaction and radical changes. During that harsh period when myriad CEOs were trying to save their companies by mass layoffs of people, Intercar’s owner decided to invest in his, believing that they, properly developed and led, would take the company to a new level. Following the approach he learned from Toyota, teams were formed and were taught to perform cross-functionally. Gradually, they were coached on how to assess each other’s capability and productivity, measure current losses and propose corrective actions, learning through doing. Continuous Improvement training was organized according to knowledge-empower teams to restructure themselves around value streams.

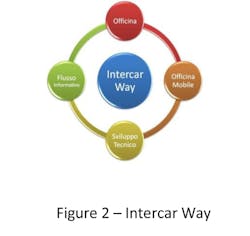

The PDCA circle was rolling its way to The Intercar Way, a well-built structure as represented in Figure 2 as an integrated collective working towards a common goal. One result of this was that maintenance workers began going on sales calls with sales people and were able to explain to the customer opportunities for productivity improving sales. Since they had also learned about and practiced continuous improvement, they were able to suggest changes to the customers’ processes that also improved customer productivity.

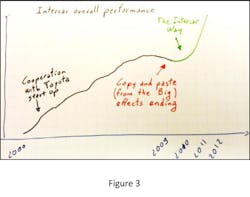

Overall performance in the last 13 years is depicted in Figure 3. What specific outcomes has this investment yielded? Apart from an increase of 30 % in sales and productivity and 90% growth in spare parts sales, it spawned a continuous learning and teaching environment where people are encouraged to reach their top potential. Intercar people are committed to the company ,as indicated by average employee tenure of 15 years with the organization.

The Intercar case illustrates the power of investing in people. There does not have to be formal academic credentials—only 5% of Intercar’s people have a university degree. People’s potential and work ethic is what matters most for your investment to pay off.

_______________________________________________

Liker Leadership Institute (LLI) offers an innovative way to learn the secrets of lean leadership through an online education model that is itself lean, and extends that lean education far beyond the course materials. Learn more about LLI's green belt and yellow belt courses in "The Toyota Way to Lean Leadership" and "Principles of Lean Thinking" at the IndustryWeek Store.

About the Author

Joseph.Ricciardelli

Coach for Lean Leadership

Joseph Ricciardelli is a founding partner at Tecla Consulting. He is an expert in lean management, World Class Manufacturing (one of only 13 certified Fiat MTU trainers for WCM in the world), and TPM - JIPM. He holds a PhD in mechanical engineering, with more than 20 years of experience as an international consultant throughout Europe, the United States, India, Mexico and Russia. He promotes systematic and customized building of continuous improvement programs (in small, medium and multinational companies) from the foundation level up to the sustaining phase, built upon a real people development within the company. His client portfolio is centered on both the service and manufacturing sectors (Automotive, Logistics, Food and Beverage, Packaging, Injection Molding, Construction). His main strength is that he has had opportunities to practice what he has been preaching, having previously held a position of a plant manager, bringing the company from near-bankruptcy to an award winner. Ricciardelli is also an associate professor at Master Studies for Entrepreneurs at CUOA.