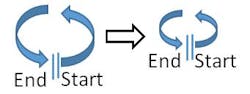

Sometimes I say “wax on” as I gesture. It has become a joke about the way I am constantly moving my hand in a circle as I describe the flow of people, equipment, processes and PDCA. It looks like I am channeling the sensei from Karate Kid, but the importance of the circle versus the line is no joke.

Operators walk down the line, pass the part to the next process or operator, and walk back to their start point empty-handed. Material handlers pick up pallets from the dock, put them into the warehouse, and return to get the next pallet with empty forks. Full trucks drop off their cargo and head home with an empty trailer or no trailer at all.

Empty hands, empty forks, and empty trailers are all waste. Traveling further than needed with 50% utilization is not the concept of flow, or of lean, or a formula for business success.

The characteristics of a circle help to conceptualize and remember important aspects of flow. And it is fun.

4. Circular, but not circles. A circle is rarely the optimal path. The benefits of the “U” shaped cell are well known, but any shape that has the start and end close together, does not cross and minimizes total distance is a winner. The advantages of having a short distance from one side of the path to the other include being able to rebalance work load, ability to add or subtract resources to match demand, and not having to travel the full route when not required.

A straight line of processes from receiving to shipping is a definite improvement over chaos, and it looks sexy on the CAD drawing, but it almost guarantees that even as the parts and processes may have minimum travel, that the people and material handling equipment will be traveling empty half the time. The route map with nice arrows on a map showing delivery routes is exciting, but has to have arrows coming back.

Circles are better than lines. Wax on.