Getting to the Root Cause of a Poor Customer Experience

Recently, I was chatting with longtime colleague and friend, Keith Essency. I first met Keith when I worked in the Motorola Semiconductor business in marketing and he was on the engineering side. We were talking about process and root cause analysis for something he is tackling (a nod to all my fellow Motorolans from the process mapping era).

Later the same day, I was on a call with a client who wanted help addressing a number of recent customer experience failures. He said, “There’s been a different reason in each instance. We fix that reason, but then we see a repeat of the problem with a different customer. It seems like we’re in a break-fix vicious cycle. How do we get out?”

A Simple Technique to Tease Out the Root Cause

It occurred to me that my conversation with Keith on the topic of 3X5Why analysis would be an applicable technique to help this client. Many manufacturers use the 3X5Why approach as part of their quality process, to address such things as equipment or product failures. It can also be applied to “breaks” in other areas, such as marketing and customer service.

For those of you not familiar with 3X5Why, it is often used to address non-conformance issues. To paraphrase supply chain expert John Casey, this is a method to identify causes and help you see issues that broadly effect the overall process.

The benefit of this approach is that it changes your focus from reacting to individual issues, to fixing the processes that cause the issue.

The goal is to understand and tease out the root cause for three primary dimensions:

· How did the problem occur? (“specific process break”)

· How did the problem escape detection? (“detection failure”)

· What occurred in the system that enabled the specific process break.

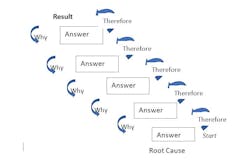

For each of these three dimensions, sometimes referred to as “legs,” you apply a technique that repeats the question “Why?”

As you move from asking “Why?” each time, the goal is to identify the cause and effects—peeling the onion one layer at a time until you get to the core of the problem, or root cause. Seems simple enough.

And it is, as long as you can keep the logic straight. For the method to work, it is important that the information is on the critical logic path.

One way to make sure the logic holds is to insert the word “therefore” into the chain. Starting with the last “Why?”—your fifth one—add the word “therefore” between each step. If the logic chain holds in reverse, then it is probably solid.

Ultimately your chain would look something like this:

A Useful Application to Make Your Customer Experience Better

I explained this process to the customer. He said, “What we’re doing isn’t working, so let’s try it.”

I asked him for the top issues impacting the team and business due to customer experience problems. After some discussion, we decided that several of the customer experience breakdowns were causing “low conversion from pilot to production.”

We scheduled a working session. As part of the process, we delved into the analysis, starting with the result. The first “Why?” focused on the first leg: Why did the problem or result occur?

We framed the question as: “Why are the conversions from pilot to product so low?” The first answer that was in common across several of the critical pilots was: “The pilots stalled out.”

The natural next “Why?” was: “Why do the pilots stall?”

That led to this answer: “The customer had trouble integrating the product into their process.”

Next up: “Why did the customer have trouble integrating the product into their process?” We continued in this fashion, answering each “Why” until we teased out the root cause, and then we made sure the logic chain worked in reverse. We then tackled the remaining two legs.

Once we mapped it out, three issues bubbled to the surface:

· Because many pilots were rushed to close at month-end, a key step in configuring the pilot was left out.

· The problem escaped detection early on because the implementation team had a configuration standard it used if the pilot lacked a unique specification. But that standard didn’t reflect the customer process.

· The push to close deals by month-end to support sales quotas allowed the problem to persist.

The company addressed each of these dimensions, which resulted in several changes to the pilot acquisition, onboarding, and implementation processes. They created a communication plan and formed a short-term tiger team to support the changes.

Fixing the Breakpoints Results in Happy Customers

Breakpoints anywhere in the customer experience serve as moments of truth. It may be necessary to patch a break quickly to address a specific customer issue, such as change out a product at no cost or provide free technical support. However, if a break continues to occur across multiple customers, then it is important to understand the root cause on all three dimensions to keep the problem from persisting. This process takes some discipline, but positive customer experiences are worth the effort.

Positive customer experiences boost retention, repeat purchases, increased share of wallet, and word-of-mouth referrals—all good things for the bottom line.

Laura Patterson is president and founder of VisionEdge Marketing.

About the Author

Laura Patterson

President

Laura Patterson takes a practical, no-nonsense approach to proving and improving the value of marketing. Laura began her 25-plus-year career in sales and had the great fortune of working across functions spanning customer relationship management and marketing. Today she is at the helm of VisionEdge Marketing, founded in 1999, and is a pioneer and authority in the marketing performance management (MPM) discipline. The company specializes in helping companies apply data, metrics and proven best-in-class practices to improve marketing effectiveness, deliver business impact and enable better business decision-making. Laura and VisionEdge Marketing are all about making marketing an engine of growth for organizations. Martechexec selected Laura as one of the top 50 women in marketing technology. Laura serves on the University of Texas McCombs School of Business Masters of Marketing Science Advisory Board.