Workforce and Lean Strategies Help Keep Manufacturer in the US

This is the second of my three-part series about Firstronic CEO John Sammut, a seasoned manufacturing pioneer who knows how to drive manufacturing growth from operations in the U.S. Read the first part: Who Says You Can't Manufacture Electronics in the US? and the third: Leveraging IT for Competitive U.S. Production.

Moody: Let’s talk about the workforce. There’s a lot of buzz about the U.S. just not having enough of the kind of workers that we need. What do you think?

Sammut: My feeling has always been that ultimately competitive advantage comes down to the people. We can buy the equipment and materials anywhere, but the difference between us and our competitors is the people. It’s a different approach for HR -– at EPIC we handpicked the best people for any given position. I think that’s one of the major success factors.

The IndustryWeek Leader of the Week highlights the manufacturing leaders, executives and stars who are driving growth in today's industry and helping to shape the future of manufacturing.

Likewise Firstronic has management team capabilities well above our company size -– each executive has managed a company ten times the size of this one. You have to “frontload” the staff for the size you expect to be in five years, and the challenge is you have to afford it -– don’t go after the least expensive.

If you get the best, you will get to the size you want a lot quicker. If you take the five top performers, they will perform like 10, get paid a seven, you are ahead of the game every time.

So the bottom line is picking the best people -– like the NY Yankees, they’re perennial winners -- they get the best players in the league and they win.

Y

ou want entrepreneurial people who will figure out how to compete with offshore because the only way to beat them at their own game is to create a paradigm shift and effectively change the rules in the right segments if we pick the right customers, and the right business.

We know we have advantage over off-shore because it’s not always piece price, it’s the overall acquisition costs. And when we educate the customer on total acquisition costs and how we can help them win more market share, when we do that, we show them all the elements, offer flexibility and local support -- things that ultimately allow them to win business -- it’s not always about the cheapest. We educate them on the intangibles and help them see the big picture.

I see the environment as not one company against another, but instead one supply chain against another supply chain –- we know we can be every effective there. Identifying the weakest link in the supply chain is key. Our proprietary tools and systems are important -- ProManage is our "secret weapon" –- took ten years to develop and it’s constantly evolving. [More about ProManage is in part three of the series.]

As to the operators on the floor, many of whom are direct labor placing components on a board, they may have some vocational training, but Firstronic provides extensive on-the-job training. We know that training has to be easy to learn, and in some cases it’s better if we do our own. We have rigorous programs detailed by function and we incentivize workers to go up the curve by getting trained for the next job.

Moody: What, specifically, does lean manufacturing mean at Firstronic?

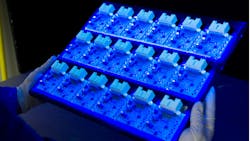

Sammut: Smaller batches, much smaller and more frequent; higher velocity, more changeovers and setups. We knew we had to get faster on changeovers and setups. Before it took two hours, now we’ve figured out how to do it in 15 minutes with SMED (single minute exchange of die) techniques. Then you can run a day’s worth of demand vs. two weeks’ worth.

How did we get it down to 15 minutes?

Basically we had to learn how to do as much preparation off-line as possible so when we were ready to do a changeover, everybody had everything prepared. The associate calls up the next program, punches a button, and we’re rolling, like a Formula 1 pit crew doing a tire-change -– they have to get that wheel off and get a new one on in the blink of an eye, and that means they need all tools, all the equipment ready line side. Everybody must be on the same page as a team. Our five-person changeover teams –- our pit crews -- practiced until they got the moves down.

Firstronic's Operational Improvement StrategyHolistic Approach to Lean Manufacturing

- Synchronous Flow Manufacturing

- Managing Constraints

- Small Transfer Batch Sizes

- Quick Changeovers/Setups

- Standardized Process/Equipment approach to minimize variation

- Workforce cross-trained to enable deployment among the operations having greatest demand

- Continuous Improvement/Elimination of Defects

- Production status highly visible to enable quick identification of bottlenecks

- Supply Chain Management Focus

- Optimized lot sizes

- Defined buffers maintained by suppliers

- Re-stocking triggered by pull signals

- Vendor Managed Inventory (VMI) limited to maximize production floor space

About the Author

Patricia Moody

Publisher

Patricia E. Moody is a writer and manufacturing and supply management consultant with over 30 years of management consulting, hundreds of articles and interviews, speeches, and 12 books to her credit. She is the publisher of Blue Heron Journal, an online resource for thought-leaders and decision makers.

Named by FORTUNE magazine one of the "Ten Pioneering Women in Manufacturing," she was featured on CNN's "21ST CENTURY WITH BERNARD SHAW." Her consulting client list includes Motorola, Respironics, British Petroleum, Waste Management, and Cisco. She consulted to Johnson & Johnson's McNeil Consumer Labs during the Tylenol poisoning crisis and is credited with saving the company. She has an MBA and an Honorary Doctorate.

A pragmatic visionary and self-confessed technology freak, she has little patience for laggards who have dwelled too long on one-note methodologies. She believes that a combination of technology, clear process, and progressive leadership, funded by smart spend management can save endangered companies.