Editor’s note: Given the remarkable changes in the industrial world during our two years of COVID-19, IndustryWeek’s editors asked contributors and business leaders to share how their outlooks have been changed by the ongoing challenges. This is the final Outlook 2022 story in our series.

Industry and government resources have been trying and waning for over the past three decades to turn the U.S. into a powerhouse of clean-energy and high technology exports.

Many of us believe that the root cause problem is a frustrating and persistent shortcoming of the American economy. We could call it the “Transition to Manufacturing Gap.”

When new technologies are in the basic research stage and decades away from reaching a market, the U.S. and the investment community generously supports them. However, when those same technologies are on the verge of commercialization and being prepared for mass production, support has been shown to quickly disappear. Very few financial institutions or venture capitalists will write their innovators a loan, and no manufacturers will help work out the final details in their production line.

Since the pandemic disruption, we have all experienced the impacts to our respective economies. People have become more risk adverse and looking for where to place blame rather than taking on a leadership role in their areas of expertise.

Where I have changed over this time is that we must see things differently from the perspective of the opportunity for change. I believe that our success will be dependent upon our ability to collaborate on innovative solutions in all areas of industry, academia and the government.

A major building block for the foundation of success will be in our ability to communicate, recognize the true root cause of the opportunities that are in front of us, and to look at things from a systems perspective. We must look at addressing the problem and not just the symptoms of the problem.

We must ask:

- Why do we have supply chain shortages?

- Why do we have a shortage of skilled workers?

- What should we each be doing differently to address the environment and climate concerns?

- How do we improve the quality of life for everyone?

- How can I help others?

- ….. and so on.

We are a world that is data rich and knowledge poor. We need to take the time and work to convert that data to actionable items that we can resolve.

We have to help others to understand.

We talk about reshoring as a solution to many opportunities today. Many products that we offshored, were redesigned to move them out of the U.S. Very few understand how we got to the situation that we are in today, and it is not easily reversible.

Everyone is looking for that silver bullet that will be the end all to the challenges that we have today.

Well, there is no silver bullet!

Our society is great at responding to a crisis, but now we need to be preemptive in our approaches and prevent those problems from ever happening. A problem here is that we set our business metrics and rewards up that do not drive this preemptive behavior. Management, union leadership and employees all agree. Yet, in spite of widespread agreement, very few organizations do a very good job of creating an environment that allows innovation to happen and maximizes innovative output.

This failure of most organizations to achieve outstanding, innovative, results is really not surprising. Innovation is a complex topic that is influenced by a plethora of interacting factors. Because of this complexity, it is very difficult for organizations to get all of the factors right, at the same time, to provide the results that everyone wants.

The economic superiority of America continues to depend on technology to detect and deter potential aggressions. Such technological capability demands ongoing investment and implementation of innovative manufacturing and product design technologies to preserve America’s defense, technical and economic superiority against strongly growing foreign competition. The metals casting industry has been one area that has been lagging in advancements due primarily to proprietary interests. Evolving requirements have even placed a stronger need to accelerate this collaborative approach.

Over the past several decades, we have tried to close what is referred to as the Valley of Death—the gap between early technological development at the university level where public grants provide research funding and product test and launch functions funded by corporations. In the middle are functions such as technology prove out and demonstration where neither corporations nor universities tend to offer much support.

This challenge continues to be a problem for us, and how our team now looks at this is how to bridge the gap, rather than to close it. If we keep doing what we have always done, then we will keep getting the same results.

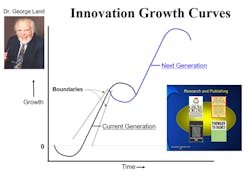

We must look at these opportunities differently by looking to the future. We need to put ourselves in the ideal end state that we desire and then look back in time to see what the steps were that we took to get there. My good friend, the late Dr. George Land, helped me to see these innovation growth paths from a totally different perspective:I use these concepts for both product and manufacturing process design.

We must be advancing our manufacturing world at an exponential rate so that we reside in the 22nd century thereby enabling new design frontiers.

The change emergence is a tough task and requires leadership from us all. We must provide the energy, drive and direction to our teams and then that in turn, must be multi-directional.

History is important in that it shows us where we came from. Now, we must define where we are going to.

Don Deptowicz is president and manufacturing visionary Aspen Hybrid Technology Solutions LLC.

About the Author

Don Deptowicz

President and manufacturing visionary Aspen Hybrid Technology Solutions LLC

Don Deptowicz is a results-oriented senior executive with an outstanding track record in engineering, program management and quality. He excels at being an inspirational and resourceful leader. He is known for innovative and creative thinking in the areas of both product and process designs involving advanced materials and coatings. He is an exceptionally skilled communicator, with the ability to build effective and productive working relationships across all levels of the organization and the value chain.

Don graduated from Purdue University and began his career in 1976 at UTC’s Pratt & Whitney Engine Division in West Palm Beach, Florida. Here, he led fundamental changes in both product and manufacturing process technology, covering the full life cycle of Military Aerospace Propulsion Systems.

Don has over 45 years of experience in the aerospace, automotive and electronic industries. Prior to this, he was the Director of Technical Excellence for PCC Airfoils LLC, where he championed the collaborative effort across engine OEMs and casting suppliers in conjunction with the Air Force Man Tech vision of Attaining Next Generation Agile Manufacturing.