Reshoring Is on the Rise: What It Means for the Trade Debate

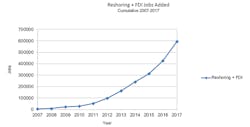

Reshoring and foreign job announcements (FDI) surged in 2017 to over 170,000 U.S. manufacturing jobs. This is strong evidence that work can and will be successfully brought back—and is especially relevant in a time of intense debate over tariffs and the trade deficit.

All told, job announcements were up 52% from 2016, and a whopping 2,800% from 2010. Announcements lead to hiring typically within 6 to 24 months.

There is substantial potential for many more jobs to come back, if the right policies are implemented going forward.

Implications for the Economy and Manufacturing

President Donald Trump has announced tariffs on solar panels, appliances, steel, aluminum and a broad range of Chinese products. His aim is to eliminate the $700 billion/year non-petroleum goods trade deficit, thus increasing U.S. manufacturing by about 40%--about five million jobs.

Many observers question these actions based on likely retaliation and higher U.S. consumer prices. Others question the feasibility and wisdom of trying to increase manufacturing’s share of the economy by bringing back to the U.S. the industry that we have lost over the last 40 years.

We observe from our 2017 data on reshoring, combined with other Reshoring Initiative reports, that:

• It is now clear that U.S. manufacturing, including foreign-owned plants, can be started up or grown to support a substantial flow of work back to the U.S.

• U.S. and foreign companies increasingly recognize that it is in their interest to supply more of the U.S. market by local production and sourcing.

• Based on timing of announcements, much of the surge was due to the anticipation of lower taxes and regulations and higher tariffs. To bring back more than about 10% of the five million offshored jobs will require more U.S. competitiveness, more leveling of the playing field—including some combination of lower USD, stronger skilled workforce training, still lower corporate tax rates, and a VAT (Value Added Tax).

• Bringing so many jobs from offshore disproves the weak claim that only 4 to 13% of the decline in manufacturing jobs has been due to offshoring, with the rest to automation. If so few had been lost to offshoring, so many could not be recovered in one year.

In addition to federal policy, states and cities need to play a role:

• Some states are more attractive and effective as destinations. The Southeast and Texas have dominated. The Midwest is now moving up in the rankings. Government incentives are the most frequently mentioned motivating factor

• Education and skills training need to be improved in almost all regions. Skilled workforce is the third ranked driver of reshoring and FDI.

• Infrastructure is highly ranked.

Companies can profit from the data below—here are some things to keep in mind:

• Skills training is a corporate responsibility. Some companies have taken that responsibility; others have ignored it. Without a larger and better trained workforce, the flow will decline rapidly. Skilled workforce is the third highest ranked motivator of reshoring.

• Industry 4.0. Automation, productivity, innovation and lean collectively are the highest ranked enablers of reshoring. Have you optimized?

• See which industries or companies are reshoring. Join them or sell to them.

• Reevaluate offshoring. Recognize and quantify the frequently mentioned costs and risks. For example: quality, delivery, inventory and IP risk are often ignored when offshoring.

• Made in USA branding is the fourth-highest rated factor. Would increased volume and a moderately higher price cover the cost differences on some products?

Still Much Work to Do

More than half of the increase in manufacturing jobs in the U.S. since the employment low of 2010 has come from reshoring and FDI, and 90% of the total in 2017.

When measured by our trade deficit of about $500 billion/year, there are still three to four million U.S. manufacturing jobs offshore at current levels of U.S. productivity, representing a huge potential for U.S. economic growth. Measured by our $700 billion non-petroleum goods trade deficit, there are about five million jobs still offshore.

What Drives Reshoring and FDI?

Understanding the reasons other companies have given for reshoring is helping companies determine which of these factors apply to them also. (You can evaluate a broad range of costs and risks using the Total Cost of Ownership Estimator.)

According to one survey, about 60% of companies decided to offshore based on comparing wage rates or ex-works prices. Much of the strength of the reshoring trend has been due to companies becoming familiar with a broad range of factors (costs and risks) they had previously ignored.

The factors in reshoring that significantly increased year-over-year include: automation, additive manufacturing, image/brand of Made in USA, lead time, impact on domestic economy, proximity to customers, tariffs, and Walmart.

Freight and delivery showed the largest declines, probably becoming less relevant due to low fuel prices and improvements in management from IoT.

What’s in Store for 2018 and Beyond?

Many huge projects have been announced but are not firm enough to include in our database. These include Foxconn in Wisconsin, Apple, SoftBank and numerous shale gas refinery projects. Some of these may prove to be just politically motivated speculation, while others will likely come to fruition.

Like 2017, 2018 results will depend largely on actual policy changes (taxes, regulations, trade, skilled workforce, tariffs, etc.) and corporate responses to those changes. Broad and steep tariffs would probably lead to temporary economic disruption. Medium-term, the disruption will likely disappear.

Longer-term, U.S. and foreign companies will understand that the United States is committed to balancing the trade deficit. The companies will shift production to the United States to avoid being excluded from the world’s largest market.

Here are some factors that may impact 2018 relative to 2017:

Likely to slow reshoring and FDI:

1. The fact that job gains in anticipation of tax and regulatory reductions may have tapped the immediate opportunities.

2. If mid-term elections shift control of the U.S. House and Senate, resulting in reduced business optimism.

Likely to help reshoring and FDI:

1. How corporate cash flow from repatriation and tax cuts are utilized. Investment, training and hiring are helpful. Stock buybacks are much less so.

2. Continued decline in the USD due to ballooning budget deficits, despite rising interest rates.

3. World growth as strong as the U.S. This should make other markets more attractive for offshore suppliers, leaving domestic suppliers with less import competition.

4. Continued increases in usage of TCO (Total Cost of Ownership) instead of price in making sourcing decisions.

5. Continued reductions in regulations.

6. Continued improvement in skilled workforce programs.

7. Environmental consciousness. Domestic supply chains are more transparent than offshore and less polluting, cutting the world’s environmental impact by up to 50%, depending on the product. Sustainability will continue to increase as a corporate strategy and will help drive reshoring and FDI.

8. Recent increases in U.S. investment, which could lead to greater productivity and innovation.

Ambiguous

1. Higher interest rates, which tend to raise the value of the USD (unfavorable) but will surely increase the carrying cost of inventory (favorable), which is increased by offshoring.

2. Possible actions on NAFTA, tariffs, trade with China, etc. Likely to be medium-to-long-term favorable for reshoring and FDI but could be temporarily disruptive.

3. Oil prices. Higher prices increase freight costs (favorable).

There is probably a 12-month lag time between the announcement or implementation of policy changes and a significant response in the trends.

The best guess forecast is that 2018 reshoring and FDI will be flat to slightly up vs. 2017’s record level of 171,000 mfg. jobs announced. Our skilled workforce supply is not yet ready to support a much higher rate of increase.

This data should motivate companies to reevaluate their sourcing and siting decisions and make better decisions that consider all of the cost, risk and strategic impacts involved. Policymakers can use the continued successes as proof that it is feasible to bring millions of jobs back, if they implement local and national strategies to improve competitiveness.

Continuation of the trend depends on companies reevaluating their offshoring. The Reshoring Initiative offers many tools and resources, which can be found at www.reshorenow.org.

About the Author

Harry Moser

Founder

Harry Moser, founder of the Reshoring Initiative, grew up experiencing the glory of U.S. manufacturing. With more than 45 years of manufacturing experience (most recently 25 years as president, chairman and then chairman emeritus of GF AgieCharmilles), Moser is a leading industry spokesman for reshoring and for developing the skilled manufacturing workforce required by reshoring.

The not-for-profit Reshoring Initiative ‘s Mission is to bring back U.S., and more generally North American, manufacturing jobs by helping companies see that, increasingly, they will be more profitable if they produce and source in or near their market.

Millar Kelley

Millar Kelley is a research analyst for Reshore Now.