Today’s manufacturers have need to look for ways to do more with less to stay competitive. Many have realized that viewing data about the business via a data analytics tool (known as “analytics”) offers them another way to discover hidden opportunities to drive even more efficiency. The challenge has been unlocking this data throughout the organization.

However, some manufacturers still have data locked in siloed or outdated systems and the idea of “upgrading” these systems seems insurmountable. Capital investments are targeted at machines that speed or enhance production, not necessarily business systems. The key to modernizing these systems however is not to follow the typical “rip and replace” approach because production still needs to happen. Manufacturers need to take a practical approach and focus on areas of the business that include automating manual processes or reducing errors.

A critical shift in thinking is realizing that times have changed—and cloud is the norm. By its nature, cloud manufacturing makes digital transformation affordable, scalable, and yes, secure. It sets the business up for a single digital system of record, eliminating silos and enables you to unlock data from all areas of your business.

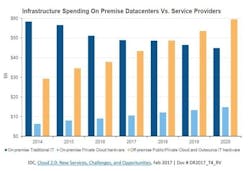

More manufacturers are modernizing and digitizing the systems that run their businesses with the cloud than ever before. IDC showed that cloud will exceed on-premise installed datacenter space by 2020. And, that roughly two-thirds of infrastructure spend by 2020 will be on cloud. This means that more processes, solutions and companies are going to run their business from the cloud.

Those manufacturers who have invested in a cloud enterprise resource planning (ERP) and manufacturing execution system (MES) solution that enables them to “turn on” operational analytics as a component of their system on record have a head start. They can integrate operational analytics more deeply to machines and enable access to non-data scientists so operations managers, quality managers, and plant managers can leverage dashboards to drive efficiency like management does on the business side today.

As the use of business analytics continues to mature, more manufacturing companies will be able to tap into the data generated by machines, sensors, and tools to augment and accelerate shop floor decisions on production, process, efficiency, quality, safety, etc. Their ability to give every plant manager, operations leader, and machine operator the contextual insights to augment and accelerate decision making will create the habits necessary for their enterprises to not only delivery business agility and responsiveness, but also to leverage future manufacturing innovation.

For more insights, download the Plex 4th Annual State of Manufacturing Technology Report.

Sponsored By: