To put it mildly, today's ERP is not what it was a decade ago. In terms of mobility, speed and actionable intelligence, technology was in its infancy at the turn of the century.

However, Andy Vabulas, CEO of Georgia-based business solutions provider I.B.I.S. Inc., says many companies are still using those primitive tools in the heart of their advanced production.

"The last time a lot of people refreshed their system was the year 2000," he explains. "The world has completely changed technology-wise in that timeframe."

For companies coming back into the market for an update from those green screens of the past century, they find a dizzying field of options before them.

Far from the simple data feeders of yesteryear, ERP systems now tout a complex array of mobile options, public and private cloud solutions, business intelligence access with dashboards, interactive displays and many other features.

Understanding this new field and finding a place to start an update project begins with one word: customization.

Miller St. Nazianz Inc.

Nazianz, Wis.-based large tractor sprayer manufacturer Miller St. Nazianz Inc. provides a perfect example of this new need for customization.

Miller St. Nazianz's products have selected options for every order depending on crops, environment and particular dealer needs, says Michael Krahn, IT director at Miller. This means that every new order has the possibility of different configurations that pull parts from different suppliers and require different manufacturing processes to complete.

A lean company, Miller St. Nazianz employs an automated process for improved efficiency all the way from order to delivery, including everything from supplier coordination to electronic kanbans.

To do this, the company depends totally on their ERP package, IFS Solutions.

"Our ERP helps us manage all of the different custom options that can go onto our machines as dealers place orders," says Krahn. "It helps manage the options as it goes into production and allows us to not only manage it as its being produced . . . but that same option data is also used for planning with our suppliers."

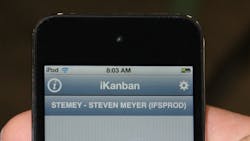

To help on the production side, the company even teamed up with a partner of its ERP vendor, IFS, to create a customized mobile app, iKanban, as part of its intensive lean initiatives.

"There is no way we could manage all this without our ERP package," Krahn says.

Customization and Responsibility

The point here is to illustrate one thing: Miller St. Nazianz requires a specific ERP system with functionality that no other user could possibly require, making it impossible to purchase an off-the-shelf system or to piece together the functionality from multiple vendors.

The only way to serve advanced companies like this today is to give them the freedom to build their own high tech solutions.

With this new focus, the pressure is off the vendors to create the perfect product, just the perfect array of functions. The task of putting together an appropriate configuration now falls on the shoulders of the users. Specifically, it falls on the shoulders of the top executives at those companies.

"CEOs, CFOs, CIOs, COOs, all the C-level guys, they need to know what their ERP strategy is," says I.B.I.S.'s Vabulas. "Good C-level people should have strategic business goals and make sure that their ERP systems will support them."

"I believe that in the end, taking this technology, you can program your business model for success and you can set the way you want the business to run," he says. "You set your system up the way you know you want it to be the most profitable."

About the Author

Travis M. Hessman

Editor-in-Chief

Travis Hessman is the editor-in-chief and senior content director for IndustryWeek and New Equipment Digest. He began his career as an intern at IndustryWeek in 2001 and later served as IW's technology and innovation editor. Today, he combines his experience as an educator, a writer, and a journalist to help address some of the most significant challenges in the manufacturing industry, with a particular focus on leadership, training, and the technologies of smart manufacturing.