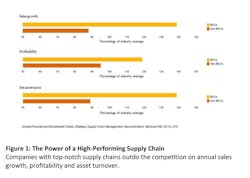

Leading companies around the world have a powerful weapon in their arsenal: a supply chain that ensures products and services are delivered to customers whenever and wherever promised. According to research by PwC’s Performance Measurement Group (PMG), companies with high-performing supply chains not only outdo the competition on key operational metrics; they also perform better on key financial metrics, including annual sales growth, profitability, and asset turnover (Figure 1). These companies exhibit superior performance on five key supply chain metrics:

1. delivery against customer request date,

2. speed of response to changes in demand,

3. total supply chain management costs,

4. total inventory on hand,

5. cash-to-cash cycle time.

What are these companies doing that others aren’t? Needless to say, their supply chains are geared to maximize cost savings and working capital efficiency, but that’s mere table stakes in today’s challenging business environment. Our research reveals that, regardless of industry, exceptional companies demand more. They take counterintuitive approaches to the way they design, operate and improve their supply chains—approaches that help them develop new sources of competitive advantage and grow the top line.

Designing the Supply Chain: Configuring the Asset Footprint

An efficient asset footprint—that is, the location and size of hard assets such as factories and warehouses, and soft assets such as order desks and purchasing teams —is critical for a well-oiled supply chain. Given the need to optimize inventory, operating expenses and taxes, you might think that the chief goal of the most successful companies is to minimize the number of supply chain assets they have to manage.

Leading companies, however, take a different approach. They begin by determining how much of each asset they need and where they’ll locate them with a view to the needs of their different customer segments. Whether the aim is to meet expectations on delivery speed or customize offerings, the configuration creates real value for the customer—and provides an important source of differentiation from the competition.

A leading manufacturer of computing systems provides an apt example. To meet the needs of its two distinct customer segments, the company set up two different supply chains, each with its own asset network. Enterprise customers—large business and government organizations—usually want computers configured with customized software, and they tend to make large-volume purchases. In-house factories and electronics manufacturing services partners manufacture and assemble products, which are then shipped directly to the customer, by air or sea depending on how quickly they’re needed. Increasingly, though, the computers are being manufactured in plants closer to the customer to shorten delivery times.

The computer maker’s other customer segment—consumers and small and midsize businesses—have different needs. They tend to buy preconfigured computers in small quantities and base their purchase decisions on price and availability; demand, moreover, is seasonal. The company set up its asset network accordingly. Original design manufacturers and in-house facilities in China mass-produce computers in quantities determined by regional demand forecasts. The computers are then shipped by sea to distributors and retail outlets.

Operating the Supply Chain: Establishing Accountability for Performance

Good supply chain performance also requires a relentless focus on results. Most companies obsessively evaluate managers in every area that impact supply chain outcomes, whether it’s purchasing, manufacturing, order fulfillment, sales, or customer service, using function-specific metrics.

By contrast, leading companies do not focus exclusively on functional performance when evaluating their functional managers. Rather, they make managers accountable for supply chain performance as a whole. These companies understand that superior supply chain performance requires cross-functional collaboration across the enterprise: Employees who take customer orders, those who manage supplier relationships, and everyone in between must work closely together.

To promote such collaboration, leading companies identify a small number of measures of overall supply chain performance. These are typically the metrics that matter most to their customers, such as product availability, on-time delivery, or delivery speed. Managers in every relevant function know how the supply chain is performing against these metrics and what each function must do to drive performance.

Take, for example, a division of a large chemical manufacturer. The company has set up measures such as costs, inventory and service delivery. Division managers monitor overall supply chain performance from the customer’s perspective. Information systems provide the newest information on delivery performance on a daily basis. Managers use that full picture to track—and improve—operational performance, with support and guidance from a central performance measurement team.

Improving the Supply Chain: Building the Right Portfolio of Change Initiatives

Given the performance advantage that leaders enjoy, one might think they focus exclusively on continuous improvement efforts, aiming to make current operations ever more efficient.

Top companies do, in fact, undertake such incremental improvements. They excel at these efforts because they consider them a normal responsibility of functional managers. But these companies understand that continuous improvement in itself is insufficient. Supply chain excellence—making changes across the end-to-end supply chain to achieve industry-leading performance—is essential as well.

So the management team oversees an ongoing portfolio of cross-functional supply chain excellence efforts to increase market share, boost margins and improve working capital. Examples include redesigning products to make them easier to order, produce and deliver; deploying a global planning process; or implementing a supply chain for a new channel. The ultimate goal of supply chain excellence efforts is to create ever more value for customers in key target markets.

A large retailer offers a good illustration of a supply chain excellence initiative in action. Known for its customer focus, the company introduced an innovation to improve the online retailing experience. Previously, customers visiting the retailer’s website were only able to see the items that were available in the company’s web warehouse; if the desired product was not available, they would buy it from a competitor. The retailer undertook a supply chain excellence initiative to make the inventory of its brick-and-mortar stores visible online. The result: higher product availability, increased sales and lower inventories. Approaches like this have helped the company grow revenue while enhancing its reputation for an outstanding customer experience.

How Does Your Company Stack Up? Questions for Your Next Meeting

• Are your company’s decisions regarding the supply chain asset footprint driven by the desire to be more efficient or to support the business’s strategic objectives?

• Are you overly focused on functional performance, or do you also use cross-functional metrics that matter to customers?

• Are you fixated on improving your current supply chain, or have you also identified the few critical supply chain excellence initiatives that will drive your strategy forward?

Three Insights

The strategies exceptional companies deploy to design, operate and improve their supply chains suggest three insights critical for aspiring leaders:

• Add complexity where it adds value, but manage it tightly. Success isn’t about removing complexity from your supply chain asset footprint. It’s about putting in place only as many assets as needed to satisfy the specific needs of your customer segments.

• Secure functional performance, but prioritize cross-functional outcomes. Achieving outcomes that matter to the customer, such as delivery cycle times, on-time delivery, and product or service availability, should be the priority. Success here requires collaboration across multiple internal organizations and external partners based on shared objectives.

• Aim for more than continuous improvement. Top-performing companies continually strive for supply chain excellence. They know that industry-leading performance is critical for maximizing value for the customer.

Flouting conventional supply chain practices takes strong leadership and courage. But as leading companies have discovered firsthand, the rewards—including stronger revenues, larger profit margins and better asset turnover—are well worth the effort.

Joseph Roussel is a partner with PwC based in France, focused on strategy and operations. He advises companies on transforming their global operations and regularly leads executive education sessions in operations innovation and transformation. He recently co-authored a book, Strategic Supply Chain Management: The Five Disciplines for Top Performance, Second Edition. He can be reached at [email protected].