Finding the Middle Ground in Supplier Negotiations

In my previous articles I’ve advanced the argument that leverage should not be used as a primary strategy for managing non-commodity type suppliers. If that’s the case, what strategy should be used? After all, there will always be differences between an OEM’s organizational goals and those of their suppliers and, because of this, points of contention will come up. So the question then becomes, “How do you resolve these issues if you aren’t going to apply an imposition of will strategy, i.e., leverage?”

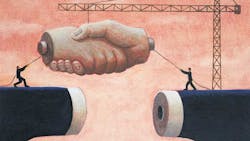

Outside of leverage, the key to issue resolution lies in “increasing the size of the pie.” A proven strategy for doing this is called “Finding the Middle Ground.” I’ve often said—and believe—that there is always middle ground, as long as both sides want to find it.

Applying leverage in negotiations results in a zero-sum outcome where one side wins and the other side loses. This typically means that the winner ends up with somewhat more than 50% of their hoped-for result and the loser gets somewhat less than 50% since, just as in sports competitions where the potential results are win-lose, lose-win and tie, the use of leverage doesn’t allow for combined outcomes above 100%. Zero-sum outcomes not only create a relational imbalance, they create hard feelings. People who lose in one negotiation often do their best to turn the tables the next time such that they win—and you lose.

Creating Middle Ground increases the size of the pie, thereby allowing both sides to realize more than 50% of their hoped-for result and yielding a combined total result greater than 100%. Sure, in the end it’s likely that one side will end up with a higher percentage of what they hoped-for. But, for instance, one side getting 80% and the other 70%—totaling over 100%—rarely creates the type of friction that results from zero-sum negotiating.

Middle Ground is difficult to find when all you are talking about is piece price, which is often the case with commodities. On the other hand, an effective way to create Middle Ground is to consider Total Cost. In using this approach, piece price is just one factor to be considered in the overall negotiations. This very point was brought up in an economic white paper recently released by the U.S. Department of Commerce, titled “Supply Chain Innovation: Strengthening America’s Small Manufacturers.” Specifically in that report the point is made that: “Consideration of this broader set of costs encourages suppliers to innovate to find new ways to maximize value for the supply chain as a whole.”

So what types of things can contribute to Total Cost, thus increasing the size of the pie? Here are some examples;

Process Capability. Many companies still rely on Receiving Inspection to ensure supplier quality. Suppliers can often statistically document that their production processes will produce part features “on target and in control,” i.e., to spec. Transfer of the responsibility for quality assurance back to the supplier can usually be done without any additional risk of non-conformance. Doing this will reduce and/or eliminate the OEM Receiving Inspection costs. It also has the potential to reduce OEM Receiving costs. When either of these things happens, this increases the size of the pie.

Increased Delivery Frequencies. Efficient suppliers can run lower lot sizes without a cost penalty. Lower lot sizes along with more frequent—and predictable—deliveries allow for reduced inventories, both in finished goods at the supplier and in raw material at their OEM customers and also reduce material handling. When this occurs without significantly increasing transportation charges—as can be the case with milk-run replenishment strategies—it increases the size of the pie.

Supplier Development. OEMs often have manufacturing expertise and resources that suppliers can only dream about. An instance of this might be in the area of manufacturing modeling software. When it makes economic sense, OEM support of supplier manufacturing improvement efforts can lead to cost reductions, lead-time reductions and freed-up capacity, etc., leading to an increase in the size of the pie.

Returnable Containers. For parts delivered on a regular, recurring basis, returnable containers can represent a cost reduction opportunity. When properly designed, returnable containers also provide for significantly reduced customer material handling both in shipping, receiving and production. After recouping the initial investment required to bring them on, the use of returnable containers will increase the size of the pie.

I could go on and on. The only limits to coming up with cost reduction opportunities like the ones outlined above are business savvy and imagination— the point being that when there are more possible financial impacts than piece price alone, there is more benefit to share.

So what can get in the way of Finding the Middle Ground? In my experience this occurs most frequently when one side can’t get out of their normal leveraging mindset where getting 100% of their hoped-for outcomes is the only acceptable goal. What, you may ask, is wrong with this? After all, isn’t getting everything you can for your company a good thing?

In and of itself, it probably is. But business success should be evaluated over the long haul and using leverage in individual negotiation events with the hope of delivering on a 100% goal will likely mean that over time you will end up getting a significantly lower overall percentage of what you are looking for in terms of financial benefit. And when you think about it, how often have you successfully negotiated for all that you had hoped for, i.e., 100%? In my experience 80% is usually considered a wildly successful negotiating outcome, even when you have significant leverage behind you.

Other things that can get in the way of Finding the Middle Ground are performance metrics that don’t reflect Total Cost. If you are measured only on Material Variance—piece price—the incentive to find an optimal Total Cost solution can be lacking. On the other hand, with a little persistence and creativity, Total Cost impacts can usually be translated into standard account exhibits. It just takes a little effort.

I contend that in the long run using a strategy that increases available benefit such that 70% or 80% outcomes for both sides are routine will end up delivering more than you would have gotten had you applied leverage. My experience is that once you and your negotiating partner get used to this collaborative type of “dance,” the outcomes for both sides start trending upwards.

To demonstrate what is probably the worst-case scenario of what happens when one side or the other adopts an “all or nothing” position you only need to look at what’s happening in Washington, D.C., and many states legislatures these days. Not a lot of Middle Ground collaboration is going on, at least from what I can tell. Would the kind of performance our politicians are delivering be acceptable in business? Not in the businesses I’ve operated in. The better and more productive alternative—both in business and politics—is to collaborate on Finding the Middle Ground.

In the next article I’ll discuss one of my favorite topics—business consultants—and how they work (and don’t work) in the supply management arena.

About the Author

Paul Ericksen

Executive Level Consultant; IndustryWeek Supply Chain Advisor

Paul D. Ericksen has 40 years of experience in industry, primarily in supply management at two large original equipment manufacturers. At the second he was chief procurement officer. He then went on to head up a large multi-year supply chain flexibility initiative funded by the U.S. Department of Defense. He presently is an executive level consultant in both manufacturing and supply chain, counting Fortune 100 companies among his clientele. His articles on supply management issues have been published in Industrial Engineering, APICS, Purchasing Today, Target and other periodicals.