Moving Quality Beyond the Factory Floor with Holistic Improvement

Humankind has been focused on quality and quality improvement for centuries, and much progress has been made in virtually every arena of society. With some exceptions, quality of life is better than it has ever been. But more progress is needed and possible as customers demand better quality, better service, and lower prices. The use of Lean Six Sigma and other quality improvement approaches has shown us that quality improvement is profitable and can significantly improve an organization’s bottom line. Individual quality methods may come and go, but improvement will never go out of style.

These are the ideas presented in ASQ’s 2015 Future of Quality Report: Quality Throughout, which spotlights major issues — which lead to major opportunities — and how a focus on quality can provide critical guidance to exploit them.

Arguably, quality improvement has been most successful in manufacturing operations. The question is how to expand this quality improvement approach beyond the factory floor to the entire organization. This is critical as an organization’s performance is a function of the entire organization. Even in a manufacturing plant, there are many non-manufacturing processes needed to ensure the plant functions properly.

It is generally agreed that there is as much improvement potential and bottom line impact outside of manufacturing as there is in manufacturing. While the cost of quality is generally in the 20%-30% range in manufacturing, it can reach as high as 40%-50% in financial and administrative processes. It’s clear that there are a number of opportunities for major improvement and that a ‘one size fits all’ approach doesn’t work as there isn’t a silver bullet that will make all quality problems go away.

Instead, a holistic approach to broad-based quality improvement is the most viable way to build and sustain a successful quality culture. This “tool-agnostic’ approach integrates multiple methods that fit the specific problem at hand. First, we need to define a holistic approach and then show how it can make an organization’s improvement initiatives more effective.

Big Picture Thinking

Looking at the big picture is an effective way to expand quality improvement across the organization, ultimately leading to continuous improvement and quality culture. Peter Drucker points out that “only the overall review of the entire business as an economic system can give real knowledge.”

In other words, a company must view its organization as a system that can be studied and improved. Systemwide improvement must provide diverse tools to improve any aspect of the business, at any location around the world, in any culture, in any business function. Integrating multiple approaches that have proven effective with specific types of problems will increase chances for success.

Holistic improvement is defined as:

“An improvement system that can successfully create and sustain significant improvements of any type, in any culture for any business.”

The characteristics of holistic improvement are summarized in Table 1. These characteristics show that a holistic approach is more than a single methodology for conducting improvement projects. The type of culture (business and ethnic), function, leadership, management systems, and other key elements of the business must be taken into account when choosing specific tools and methods.

Table 1. Characteristics of Holistic Improvement

- Applies in all areas of the business – all functions, all processes

- Applies in all cultures, providing a common language and tool set

- Can address all measures of performance

- Quality, cost, delivery and customer satisfaction

- Addresses all aspects of process management

- Process design/redesign, improvement and control

- Addresses all types of improvement

- Streamlining, waste and cycle time reduction, quality improvement, process robustness, etc.

- Includes management systems for improvement

- Plans, goals, budgets, and management reviews

- Focuses on developing an improvement culture

- Uses improvement as a leadership development tool

These improvement methods integrate a variety of individual tools and approaches such as lean enterprise, Six Sigma, “workout,” TRIZ (the theory of inventive problem solving), and the theory of constraints, to name just a few. Project identification and selection becomes a critical step in diagnosing the problem and determining the solution. The organization’s improvement system must be robust enough to handle any problem the organization encounters in the course of its improvement work and clearly requires integration of multiple methodologies for success.

Strategic Areas that Impact Holistic Improvement

According to ASQ’s 2015 Future of Quality Report, there are some strategic areas in the 21st century that can significantly affect the impact of holistic improvement, including: leadership by top management, strategic thinking, addressing mission critical projects, use of Big Data and focusing on process and product robustness to reduce the effects of human error.

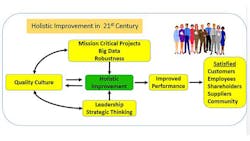

The following strategic focus items (Figure 1) work synergistically to build the quality culture needed to drive and sustain holistic improvement and improve performance that benefits all stakeholders.

Make Leadership a Priority

CEOs and top executives need to take the lead in supporting quality improvement initiatives as successful holistic change requires strong leaders to help employees move from one paradigm to another way of working. All the major quality leaders, including Deming, Juran and Feigenbaum have pointed out that quality is the responsibility of top management and CEOs like Jack Welch at GE, Chad Holliday at DuPont and Jim McNerney at Boeing have demonstrated that this approach leads to performance excellence.Strengthen Strategic Thinking

Strategic thinking is a critical aspect of leadership as it is examines the big picture, and determines an overall strategy or approach that leads to success. A lot of miscellaneous successful projects may not be as impactful as a few, carefully chosen, strategic projects. Strategic thinking is about planning, and it is central to the effective deployment of holistic improvement and creating a sustainable quality culture. Unfortunately, to-date many manufacturing organizations limit their thinking to guiding improvement initiatives in operations instead of looking at how quality methods could benefit all areas of the organization.

Create a Clear Quality Vision & Culture

A recent ASQ/Forbes Insights “Culture of Quality” white paper finds that most executives realize that a quality culture is needed to engage an organization in the pursuit of holistic quality improvement and to sustain that pursuit over time. Some tangible examples of strong cultures include DuPont’s safety culture, 3M’s focus on innovation and The Walt Disney Company’s focus on guest experience.

However, there are many companies who are still struggling with their culture and with articulating their quality vision.

In fact, the ASQ report finds that only 60% of executives say their quality vision -- the business case showing how the pursuit of quality advances an organization's objectives and elicits buy-in from senior executives -- is clearly stated. Half admit it is not understood throughout the organization and only one-third view their quality vision as compelling.

Solve Mission Critical Problems

Organizations can use a holistic approach to attack a large problem by launching multiple, coordinated improvement projects, each using different tools based on the attributes of the problem on which they are focused. In contrast, most individual improvement methods, such as Six Sigma and lean, tend to miss the large, so-called “mission critical” problems that the organization faces.

These problems typically take a large amount of time and effort to identify and solve because they show up as large, complex and unstructured. They are too big to be solved by one improvement project. For a variety of reasons, including fear of failure, management may overlook such complex problems for “lower hanging fruit” where success is almost guaranteed.

This approach can lead to winning the battles but losing the war, as a successful series of minor projects does not bring the breakthrough improvements that senior leaders expect.

Use Big Data to Help Solve Previously Unsolvable Problems

Big Data offers the opportunity for quality professionals and others to solve problems previously thought to be unsolvable. While much progress has been made in areas such as medical research and Internet marketing, one overlooked area is the design and improvement of products, services and process quality. Customer surveys can help us better understand customer needs and experiences. Collecting and integrating manufacturing data with customer data can help improve products and processes. However, most Big Data problems are large, complex and unstructured, and therefore require a more strategic and holistic approach than simply running sophisticated algorithms on the data.

Focus on Product and Process Robustness to Reduce Human Errors

Recent world disasters make it clear that improvement initiatives need to pay closer attention to human error, which is better characterized as human variation. Humans are arguably the largest source of variation on the planet. Airplane crashes, train derailments, chemical plant explosions and the like continue to happen, even when we know how to prevent them. Unfortunately, knowledgeable humans don’t always do what they have the knowledge to do.

One opportunity is greater use of concepts, methods and tools of robustness to create products, manufacturing processes and human work processes that can remain effective despite human variation. Some examples include:

- User-friendly IT and software that are robust to lack of computer literacy

- Home use medical instruments (e.g.; glucose measurement) that are easy to use despite lack of patient skill

- Pharmaceutical tablet design that minimizes patient medication errors

- Auto bumpers that are not damaged by low-speed collisions.

Improvement professionals need to do more to mitigate human variation; a major need and opportunity is to create products and processes that perform well even when faced with lack of human attention, experience and expertise. Again, holistic improvement can help quite a bit.

Improvement Never Goes Out of Style

Industry has reaped great benefit from improvement initiatives that to date have been isolated in a part of the organization; often in manufacturing. Not only must organizations look for improvement beyond the factory floor, but they must also be more strategic than restricting their efforts to the most recently publicized tool, i.e., the latest management fad or bandwagon.

The natural result will be greater enhancement of corporate performance, as well as satisfied stakeholders including customers, employees, stockholders, suppliers and the community in general. Along the way a quality culture will develop that will sustain the improvement efforts over time and continually bring significant benefits to the performance of the organization.

Ronald D. Snee is Founder and President of Snee Associates, LLC, a firm dedicated to the successful implementation of process and organizational improvement initiatives. He was employed at the DuPont Company for 24 years prior to pursuing a consulting career Ron also serves as Adjunct Professor in the Pharmaceutical graduate programs at Temple University School of Pharmacy and Rutgers University Pharmaceutical Engineering. He received his BA from Washington and Jefferson College and MS and PhD degrees from Rutgers University. He is an academician in the International Academy for Quality and Fellow of the American Society of Quality, American Statistical Association, and American Association for the Advancement of Science. Ron’s work has been awarded ASQ's Shewhart and Grant Medals, ASA's Deming Lecture Award as well as more than 20 other awards and honors. He has co-authored three books with Roger Hoerl on Statistical Thinking and Six Sigma.

Roger W. Hoerl is the Brate-Peschel Assistant Professor of Statistics at Union College in Schenectady, NY. Prior to this assignment Roger headed the Applied Statistics Lab at GE Global Research, which supports new product and service development across the GE businesses. Dr. Hoerl has been named a Fellow of the American Statistical Association and the American Society for Quality, and has been elected to the International Statistical Institute and the International Academy for Quality. He has received the Brumbaugh and Hunter Awards, as well as the Shewhart Medal from the American Society for Quality, and the Founders Award from the American Statistical Association. In 2006 he received the Coolidge Fellowship from GE Global Research, honoring one scientist a year from among the four global GE Research and Development sites for lifetime technical achievement. He used his six-month Coolidge sabbatical to study the global HIV/AIDS pandemic, spending a month traveling through Africa in 2007.